Industrial piping cold-drawing device and cold-drawing process

An industrial and clamping device technology, which is applied in the field of industrial piping cold drawing device, can solve the problems affecting the lubrication and cold drawing effect and the generation of impurities, so as to improve the lubrication effect and cleaning effect, reduce the impact and prolong the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

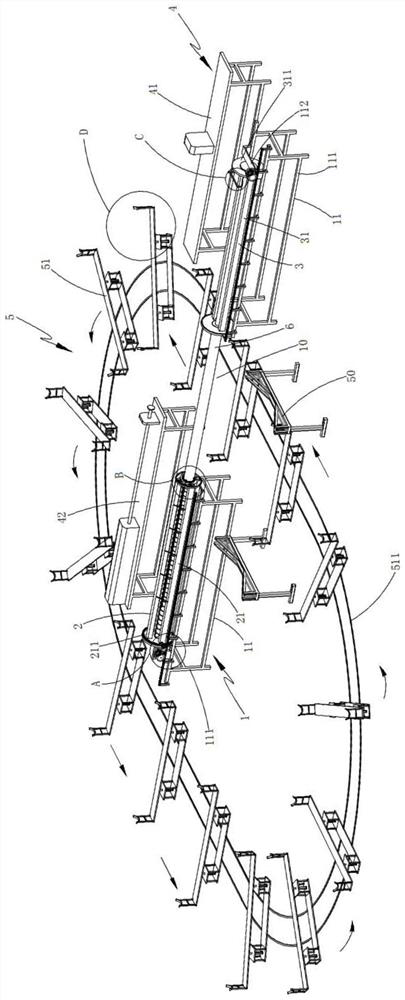

[0058] like figure 1 As shown, an industrial pipe cold drawing device includes:

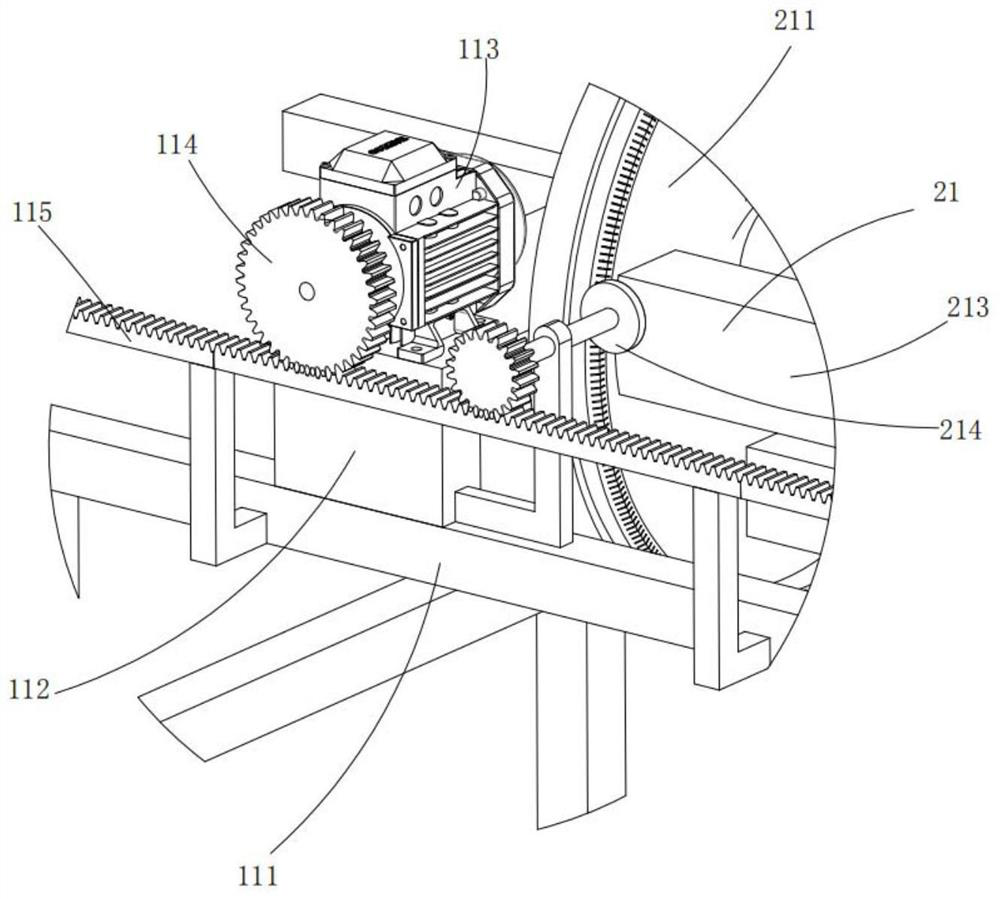

[0059] Clamping device 1, said clamping device 1 includes two moving components 11 arranged on both sides of the clamping station 10 and a positioning component 12 fixed on any one of said moving components 11;

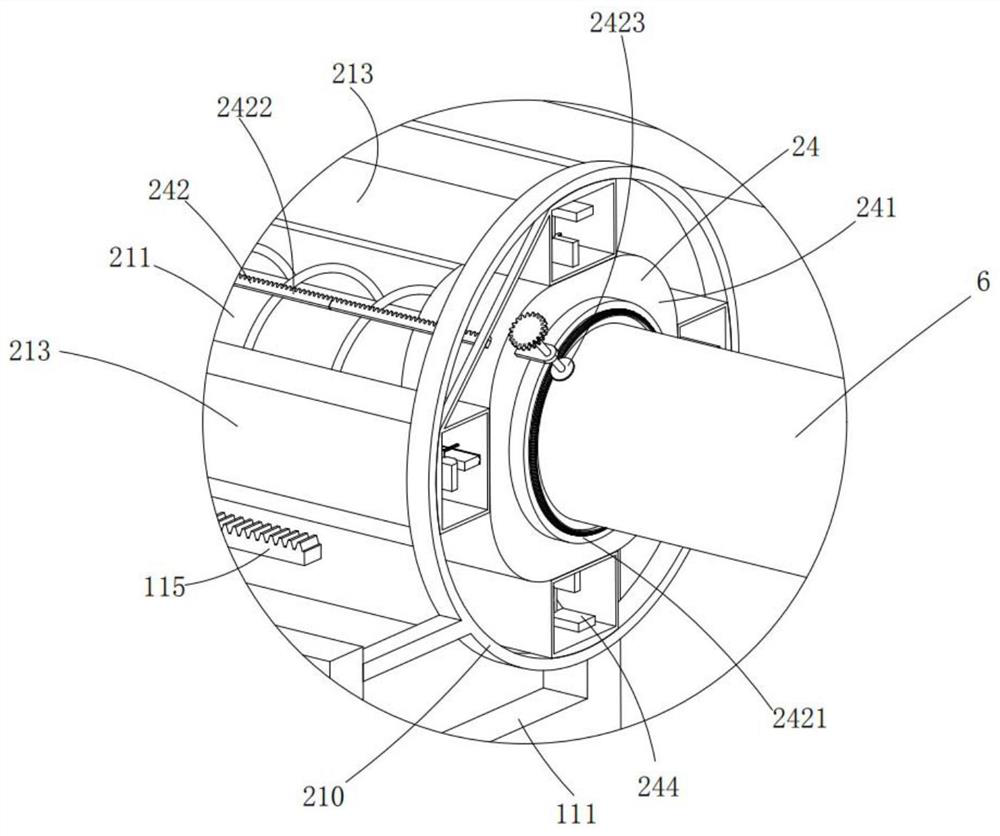

[0060] The lubricating device 2, the lubricating device 2 includes a rotating component 21 that is rotatably mounted on the other moving component 11 relative to the positioning component 12 and is facing the positioning component 12, and is installed at the center of the end of the moving component 11 The internal lubricating assembly 22 at the position, the external lubricating assembly 23 installed on the end of the rotating assembly 21 and arranged around the internal lubricating assembly 22, and the external lubricating assembly 23 which is slidably arranged on the rotating assembly 21 and drives the internal lubricating assembly 22 and the internal lubricating assembly 22. The out...

Embodiment 2

[0086] like Figure 19 As shown, the industrial pipe cold drawing process of the second embodiment of the present invention is described with reference to the first embodiment, which is characterized in that it includes the following steps:

[0087] Step 1: clamping the steel pipe, the feeding assembly 51 sends the steel pipe at the storage area 50 to the clamping station 10, the moving assembly 11 moves forward so that the limit assembly 24 cooperates with the positioning assembly 12 to clamp and fix the steel pipe;

[0088] Step 2: The cleaning assembly moves. After step 1, the moving assembly 11 on the other side sends the cleaning assembly 32 to the end of the steel pipe near the inner lubrication assembly 22 and the outer lubrication assembly 23, and the driving assembly 33 drives the cleaning assembly 32 and the outer lubrication assembly 23. steel pipe contact;

[0089] Step 3: Lubricate the steel pipe. After step 2, the moving assembly 11 cooperates with the conical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com