Insert tool

A plug-in, tool technology, applied in the direction of manufacturing tools, impact tools, light impact tools, etc., can solve the problems of drilling tool staining, high cost of drilling tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

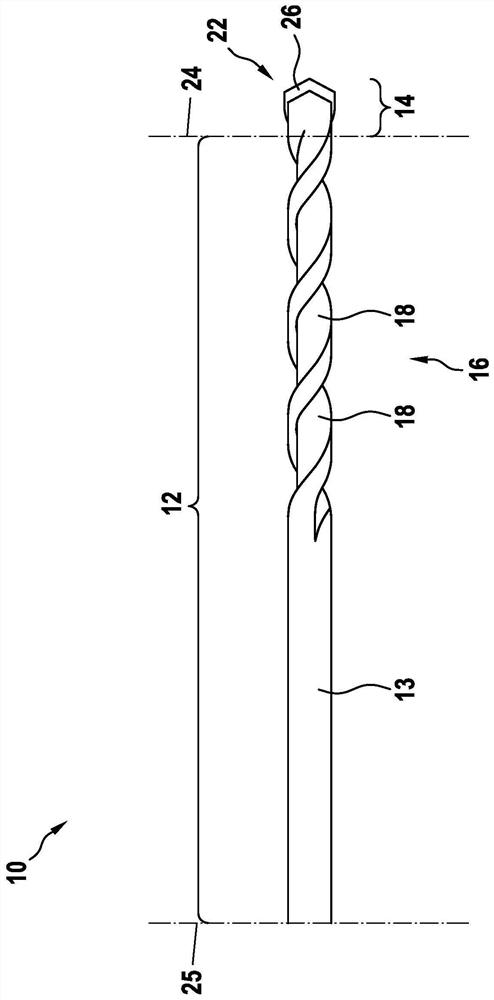

[0028] exist figure 1 A side view of the base module 10 is shown in . The base module 10 is provided for a plug-in tool 100 configured, for example, as a rock drill 102 (see Figure 5 ). The base module 10 has a first section 12 and a second section 14 .

[0029] The first section 12 includes a base body 13 and is designed, for example, in one piece. The first section 12 consists, for example, of steel. The first section 12 has a conveying screw 16 which is, for example, double-ended. Accordingly, the conveying screw 16 has two grooves 18 which extend helically around the longitudinal axis 20 of the base module 10 . The conveying screw 16 extends, for example, along approximately 50% of the length of the base module 10 and extends from the middle up to the start of the second section 14. The region of the base body 13 facing away from the second section 14 has a cylindrical peripheral surface without grooves.

[0030] The second section 14 includes a cutting body 22 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com