Anti-overloading mechanism for bending limit of flexible heat preservation and decoration integrated plate

An integrated board, anti-overload technology, applied in the field of flexible thermal insulation and decoration integrated boards, can solve problems such as breakage of thermal insulation boards, and achieve the effects of improving strength, reducing multiple impacts, and facilitating repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

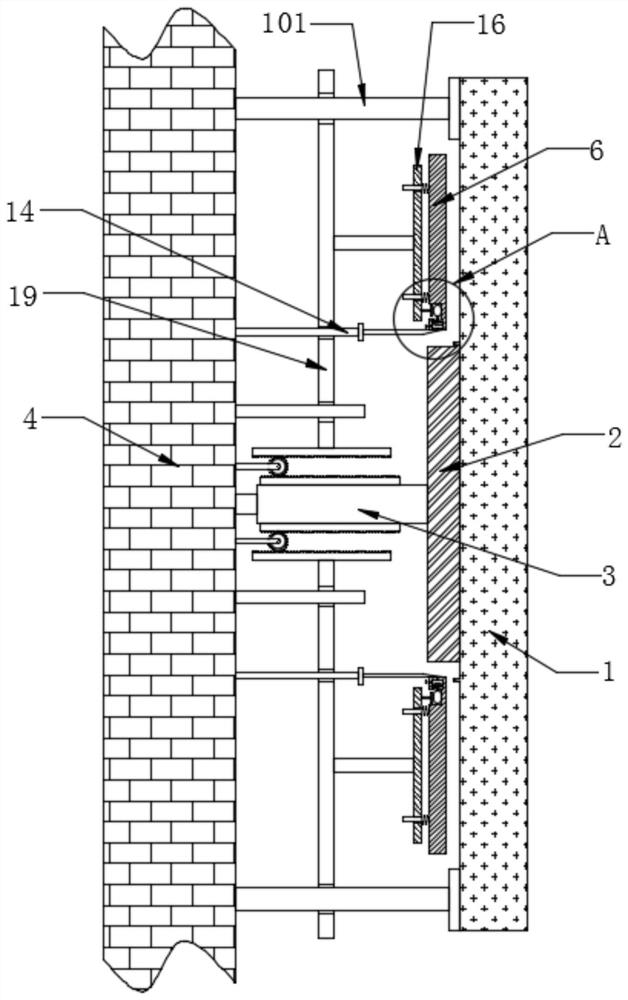

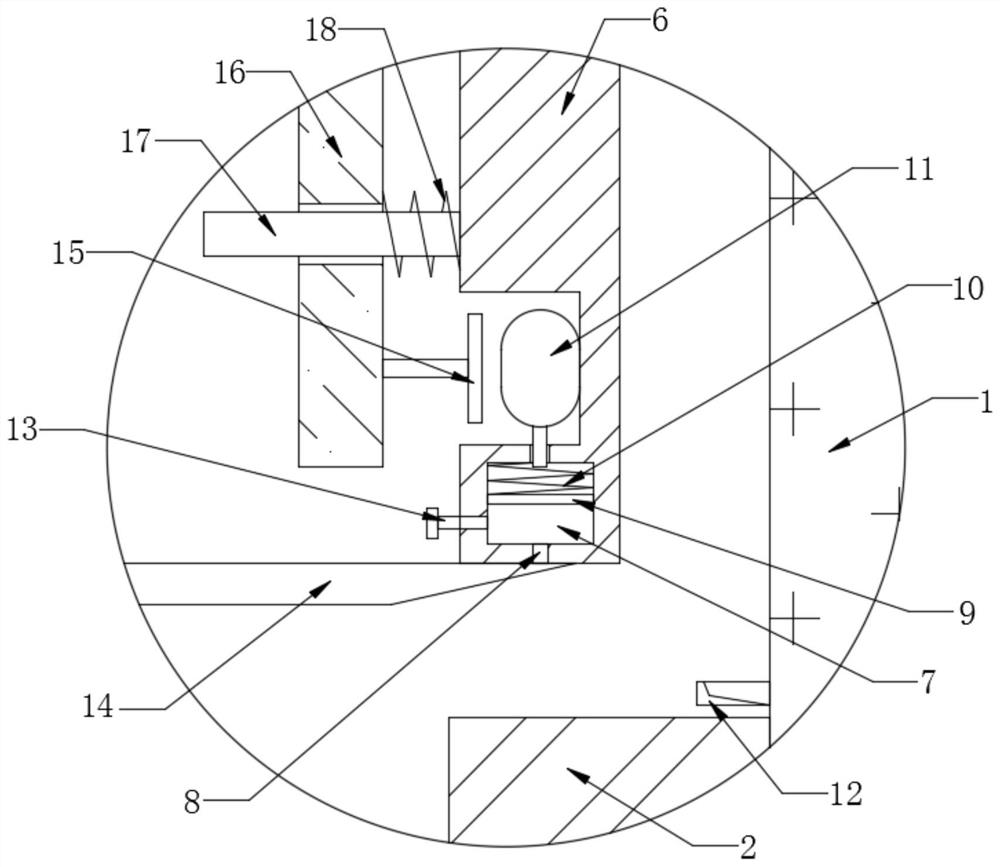

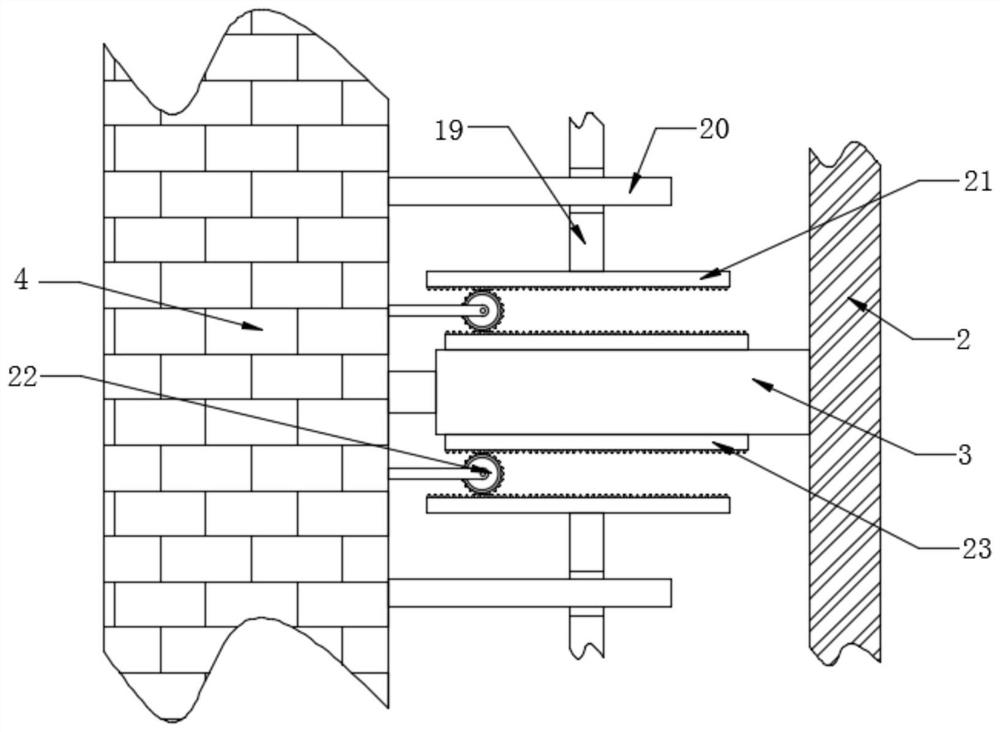

[0030] refer to Figure 1-7 , an anti-overload mechanism for the bending limit of a flexible thermal insulation and decoration integrated panel, comprising a flexible thermal insulation and decoration integrated panel body 1, a middle protective plate 2 is provided in the left middle of the flexible thermal insulation and decoration integrated panel body 1, and the flexible thermal insulation and decoration integrated panel The left end of the body 1 is attached to the middle protective plate 2, and the middle part of the left end of the middle protective plate 2 is fixedly equipped with a telescopic rod 3, and the left end of the telescopic rod 3 is fixedly mounted with a wall 4, and the right end of the wall 4 is fixedly installed with fixed columns on both upper and lower sides 101, the right end of the fixed column 101 is fixedly installed on the body 1 of the flexible thermal insulation and decoration integrated board, the inside of the telescopic rod 3 is provided with a ...

Embodiment 2

[0033] refer to Figure 1-7 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, a viscous glue cavity 7 is opened inside the sides of the side shields 6 that are close to each other, and one end of the side shields 6 that are close to each other corresponds to the viscous glue cavity. The cavity 7 is provided with a glue outlet 8, and the inside of the viscous glue cavity 7 is provided with a rubber extruding piston 9, and the ends of the extruding pistons 9 are fixedly installed with a spring 2 10, and the ends of the spring 2 10 are fixed and installed in the viscous glue cavity. On the inner wall of the cavity 7, the ends of the viscous glue cavity 7 that are far away from each other are connected with an air bag 11, and the air bag 11 is fixedly installed on the side protection plate 6, and the upper and lower sides of the left end of the flexible thermal insulation and decoration integrated board body 1 correspond to the glue outlet 8 An ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com