Temperature control printing system for rotary screen printing

A rotary screen printing and printing technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of oil seepage, air bubbles on the surface of the ink layer, and unsightly appearance in thermosetting ink printing, so as to reduce excessive residue, Uniform feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

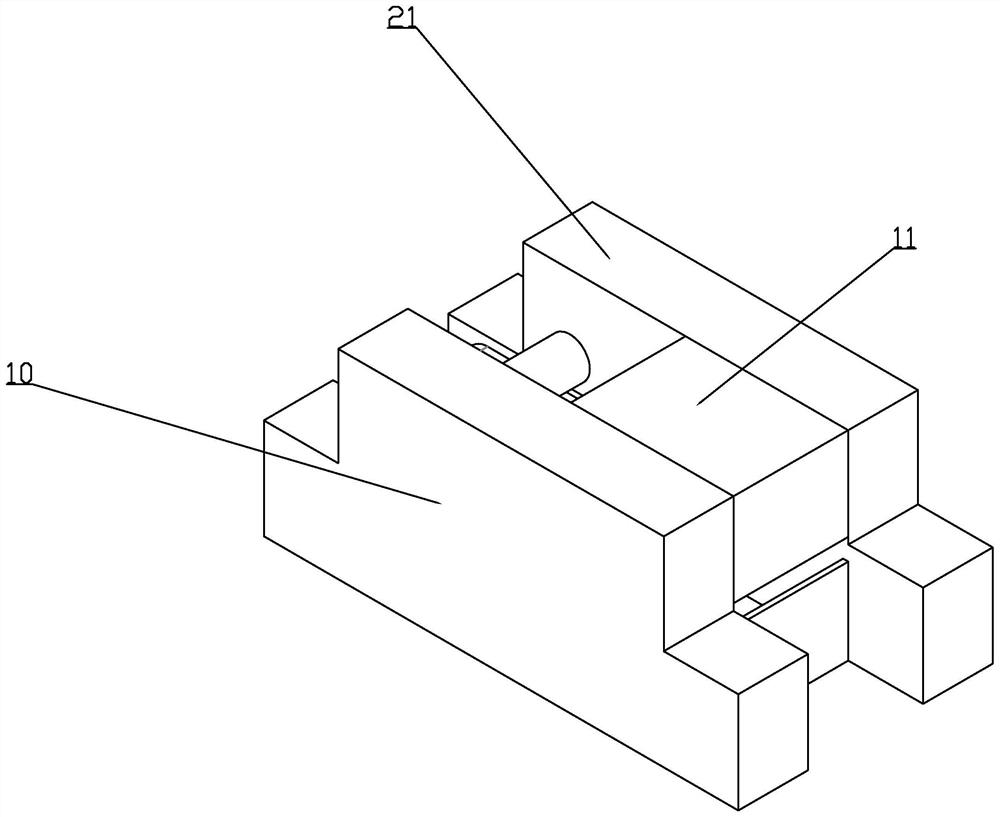

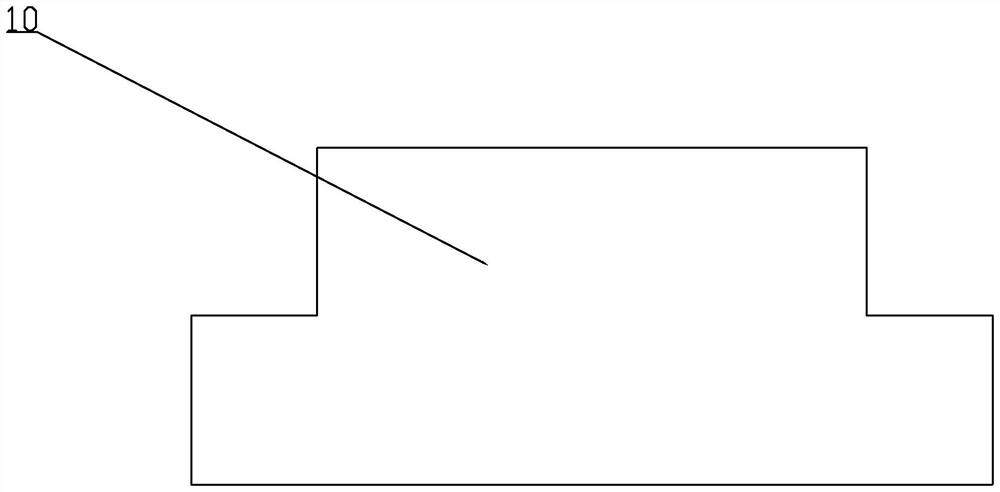

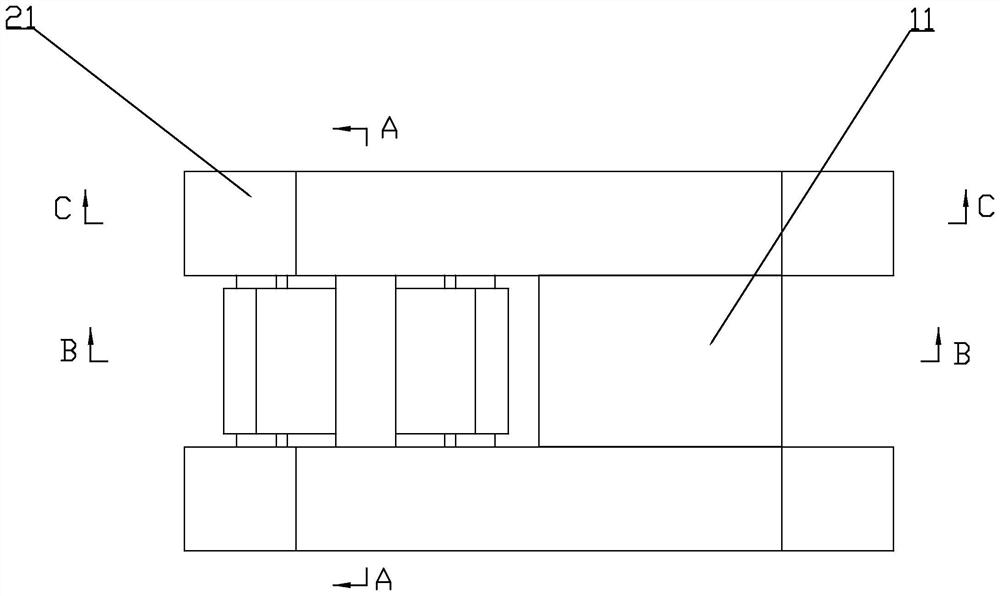

[0025] Such as Figure 1-Figure 9 As shown, a temperature control printing system for rotary screen printing includes a left casing 10, a drying box 11 is fixed on one side of the left casing 10, a right casing 21 is fixed on the other side of the drying box 11, and a left casing On the surface of one end of the body 10 close to the drying box 11, a track housing 12 is fixed away from the drying box 11, and a rotating ring 13 is slidably provided in the track housing 12, and a printing outer cylinder 22 is fixedly installed at one end of the rotating ring 13, and the right housing 21 Slidingly be provided with transmission bull gear 14 in the upper groove, transmission bull gear 14 abuts with motor gear 15, and one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com