Tray loading and tray dividing material conveying machine

A tray-carrying and tray-distributing technology, which is applied in the direction of conveyor objects, transportation and packaging, object stacking, etc., can solve the problem that tray tray positioning and tray separation cannot be realized, so as to save manpower, improve work efficiency, and reduce manpower The effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

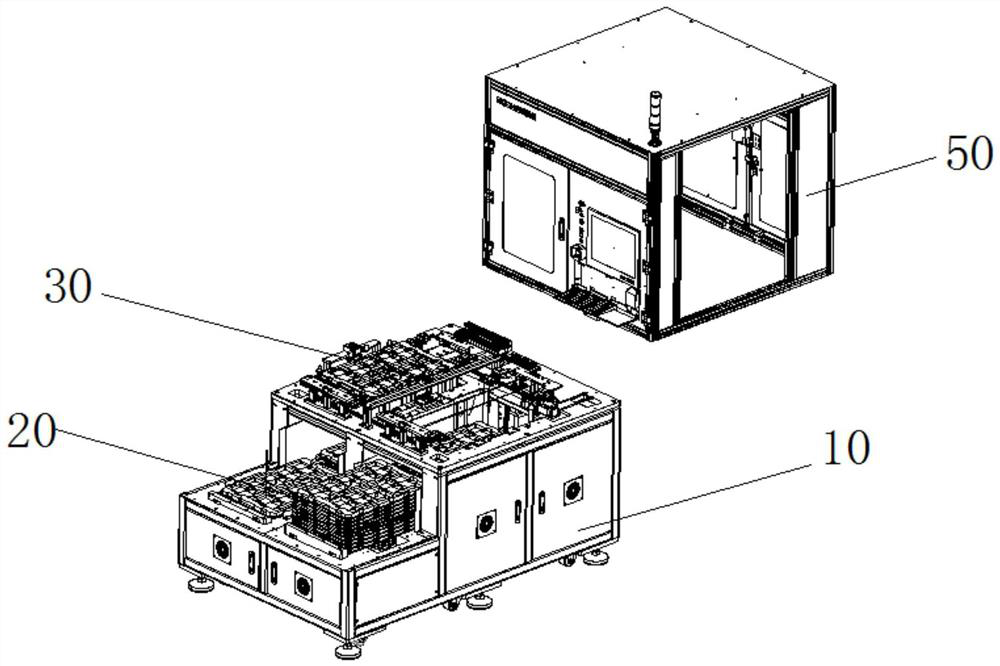

[0041] refer to figure 1 and figure 2 Shown, a kind of tray-loading machine of the present invention comprises:

[0042] A machine platform assembly, the said machine platform assembly 10 includes an upper-level machine platform 11 and a lower-level machine platform 12 arranged in layers;

[0043] The assembly line transmission component 20 is set on the lower machine platform 12, and is used for the transportation of empty stacked trays and single trays loaded with materials, including two parallel loading lines and unloading lines with the same extension direction;

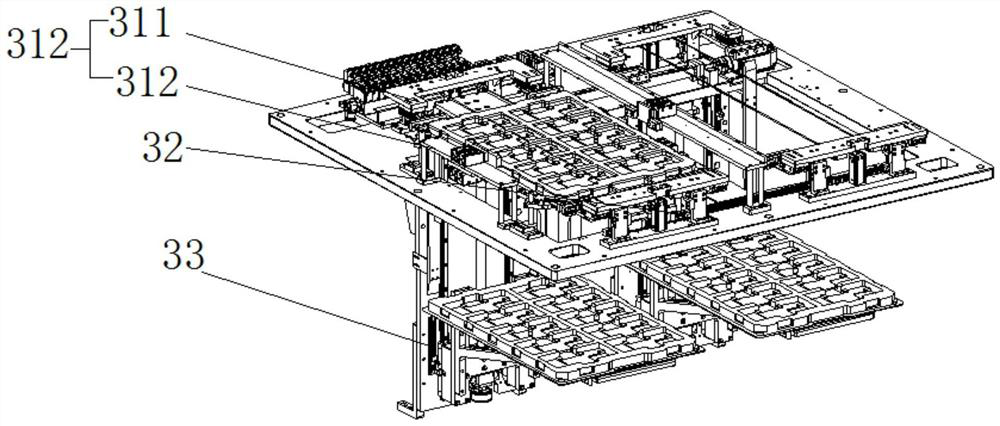

[0044] Disc handling assembly 30, comprising:

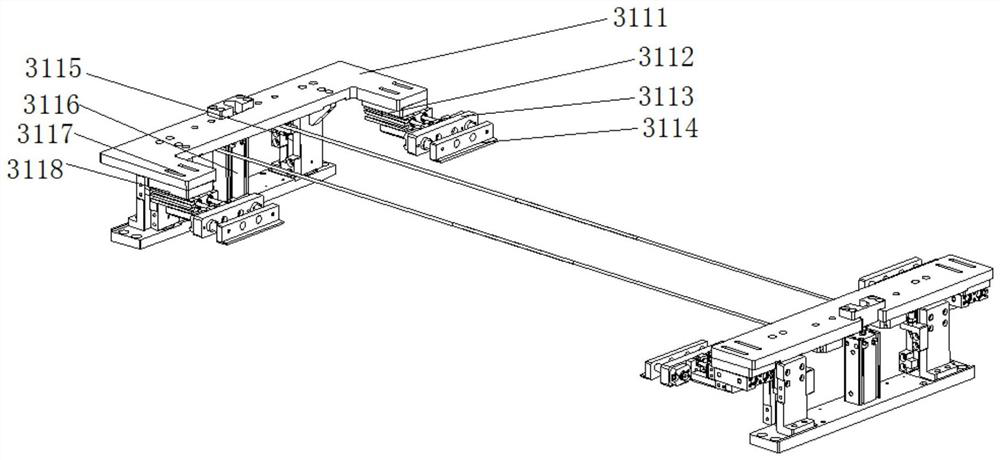

[0045] The disc dividing device 31 is arranged on the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com