Automatic refueling machine

A fuel dispenser and automatic technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of increasing staff input, prolonging the refueling time of car owners and customers, and reducing staff input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The application will be described in further detail below in conjunction with the accompanying drawings.

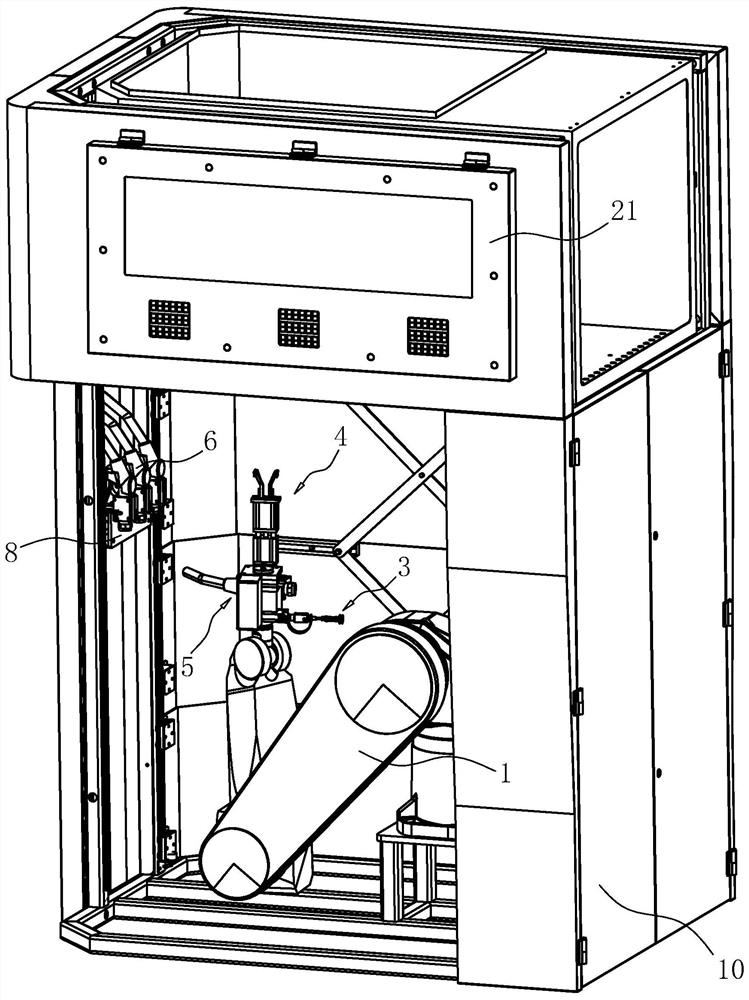

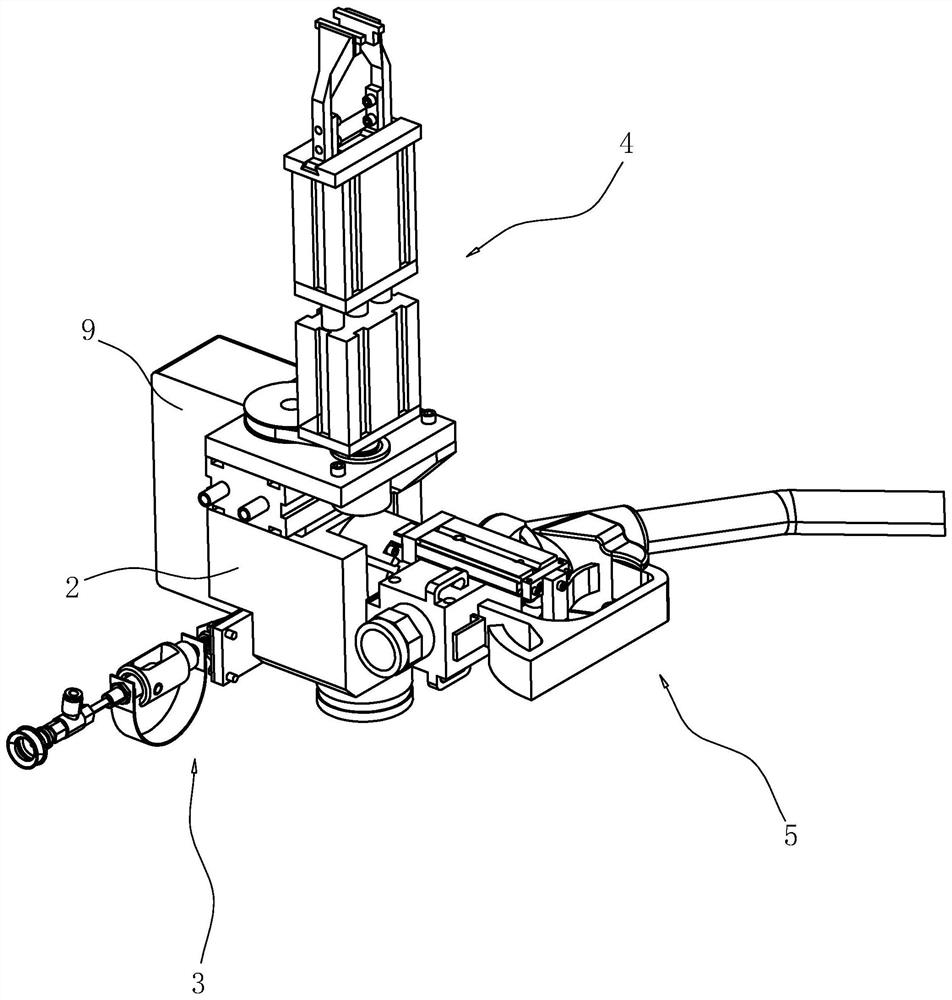

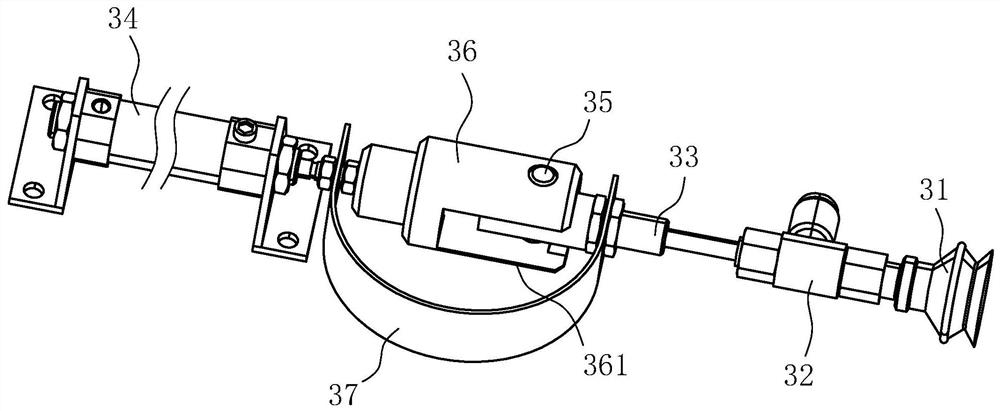

[0044] refer to figure 1 , the application provides an automatic refueling machine, including a mechanical arm 1 and a refueling robot terminal assembly arranged at the end of the mechanical arm 1. The mechanical arm 1 can be a four-axis, five-axis or six-axis mechanical arm 1, and of course A mechanical arm 1 with more or fewer joints can be used, subject to the precise positioning of the end of the mechanical arm 1 at any point in space. In this embodiment, a six-axis mechanical arm 1 is used; the mechanical arm 1 and The outer cover of the terminal assembly of the refueling robot is provided with a telescopic door assembly. Two oil guns 6 respectively connected with different oil sources; specifically, the end assembly of the refueling robot includes an outer cover opening and closing mechanism 3 for opening or fastening the outer cover of the fuel tank, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com