Backward centrifugal fan efficiency-increasing wheel disc and backward centrifugal fan

A centrifugal fan and roulette technology, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as the inability to meet the application scenarios of static pressure efficiency, and achieve strong performance, low power consumption, and static pressure efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

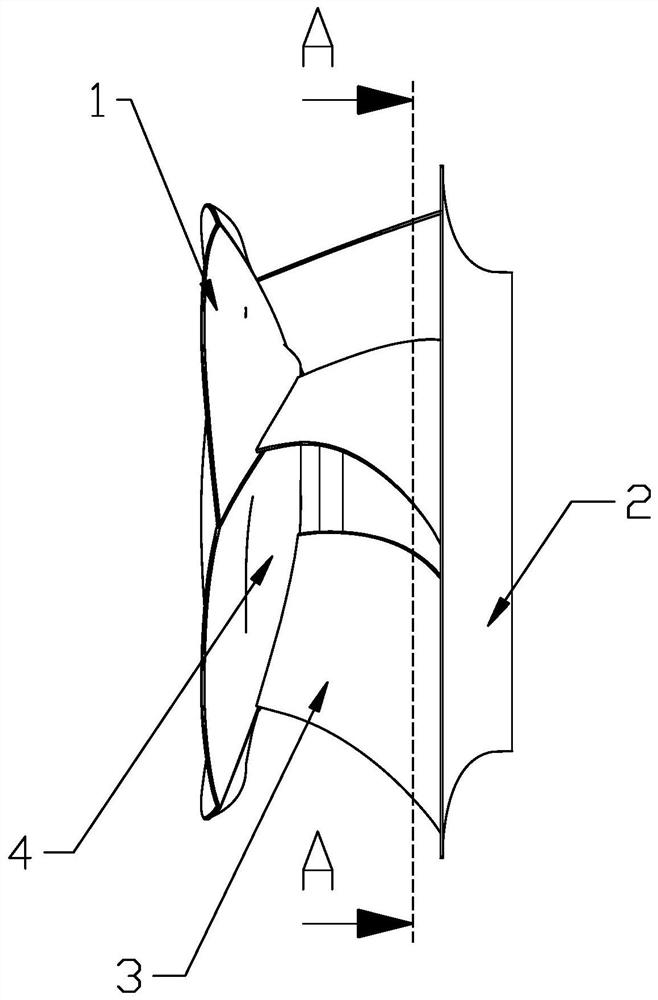

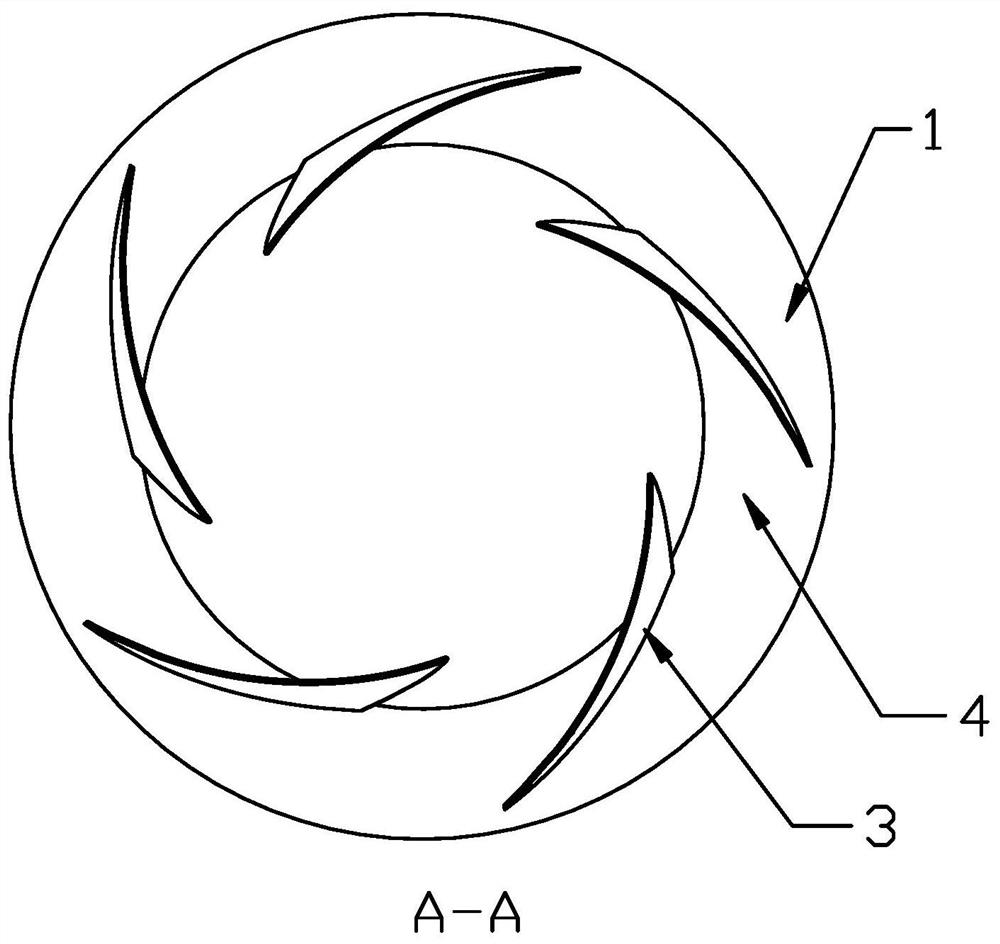

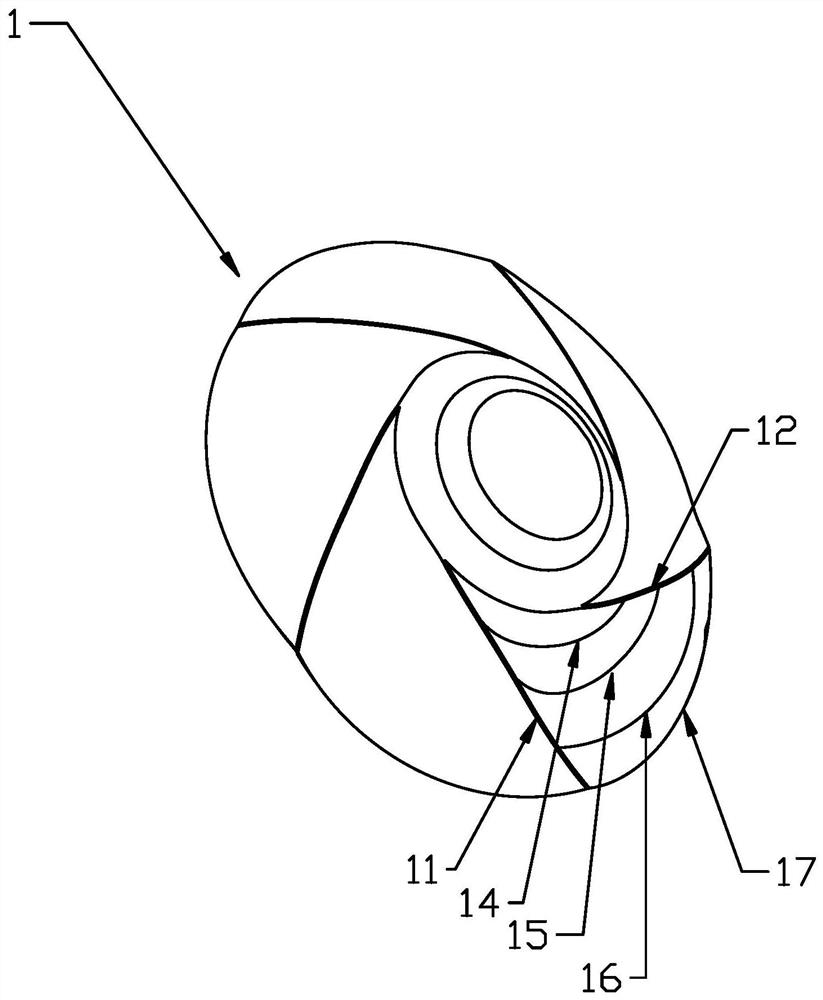

[0034] Such as figure 1 As shown, a backward centrifugal fan efficiency raising wheel 1, the wheel 1 is used to provide installation positions for the blades 3 of the centrifugal fan, and every two adjacent blades 3 are in contact with the surface of the wheel 1 and the wheel cover 2 Meridian flow channels 4 are formed between them, and the roulette 1 includes several meridian surfaces 41, and each meridian surface 41 corresponds to a meridian flow channel 4, that is, several meridian flow channels 4 divide the roulette 1 into several meridian planes 41, such as image 3 As shown, the meridian surface 41 includes a first radial profile 11, a second radial profile 12 and several circumferential profiles, the first radial profile 11 and the second radial profile 12 are any The extension line of the intersection line between two adjacent blades 3 in a meridian channel 4 and the installation position of the wheel disk 1, the first radial profile 11 and the second radial profile 1...

Embodiment 2

[0048] This embodiment only describes the differences from the above-mentioned embodiments. In this embodiment, along the radial direction, the circumferential profiles include four concave circumferential profiles and one convex circumferential profile 16, along the From the starting point to the end point of the first radial profile line 11, the circumferential profile line sequentially includes a first concave circumferential profile line 14, a second concave circumferential profile line 15, an upward convex circumferential profile line 16, The third concave circumferential profile line 17, the fourth concave circumferential profile line, the convex circumferential profile line 16 is set on the second concave circumferential profile line 15, the third concave circumferential profile line 17 , the fourth concave circumferential profile is located on the circumferential edge of the wheel 1 .

Embodiment 3

[0050] This embodiment only describes the differences from the above-mentioned embodiments. In this embodiment, along the radial direction, the circumferential profiles include four concave circumferential profiles and two convex circumferential profiles 16, Along the direction from the starting point to the end point of the first radial profile line 11, the circumferential profile line sequentially includes a first concave circumferential profile line 14, a second concave circumferential profile line 15, a first convex circumferential profile line line 16, the third concave circumferential profile line 17, the second upward convex circumferential profile line 16, the fourth concave circumferential profile line, the fourth concave circumferential profile line is located on the periphery of the wheel disc 1 towards the edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com