Sliding rail assembly

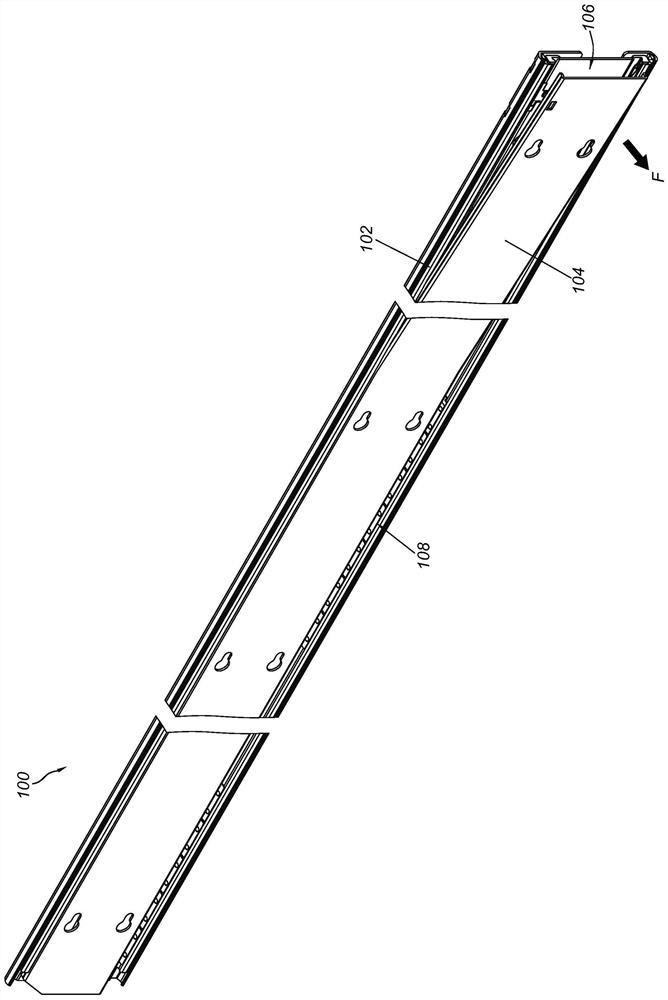

A slide rail assembly and longitudinal technology, which is applied in the field of reliable slide rail assemblies, can solve the problems of detachment, inability to displace the first rail 102, and failure to install the second rail 104 correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

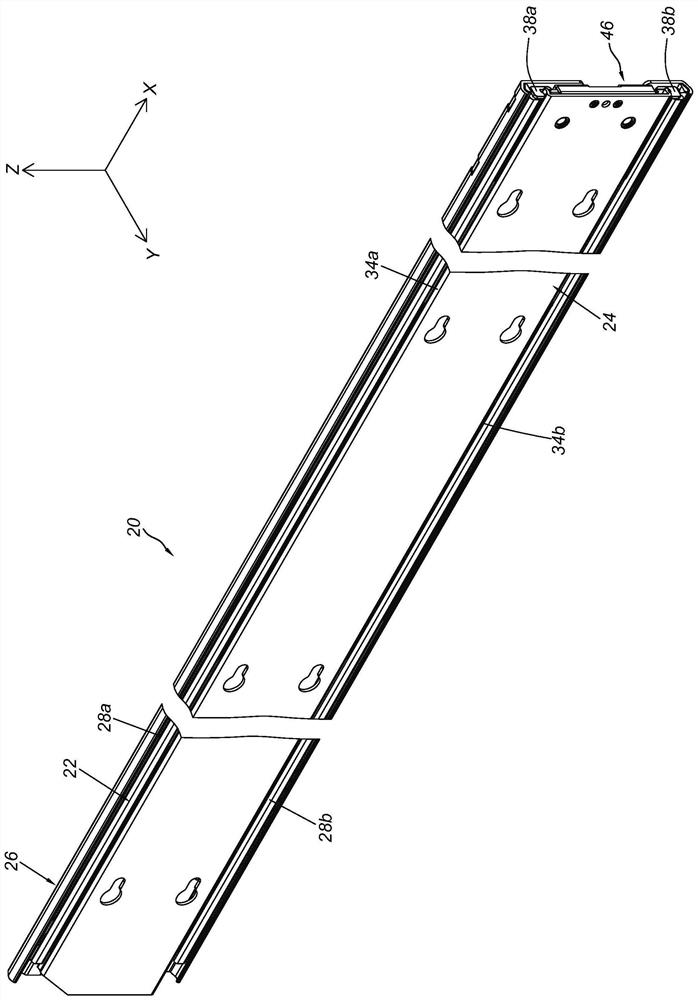

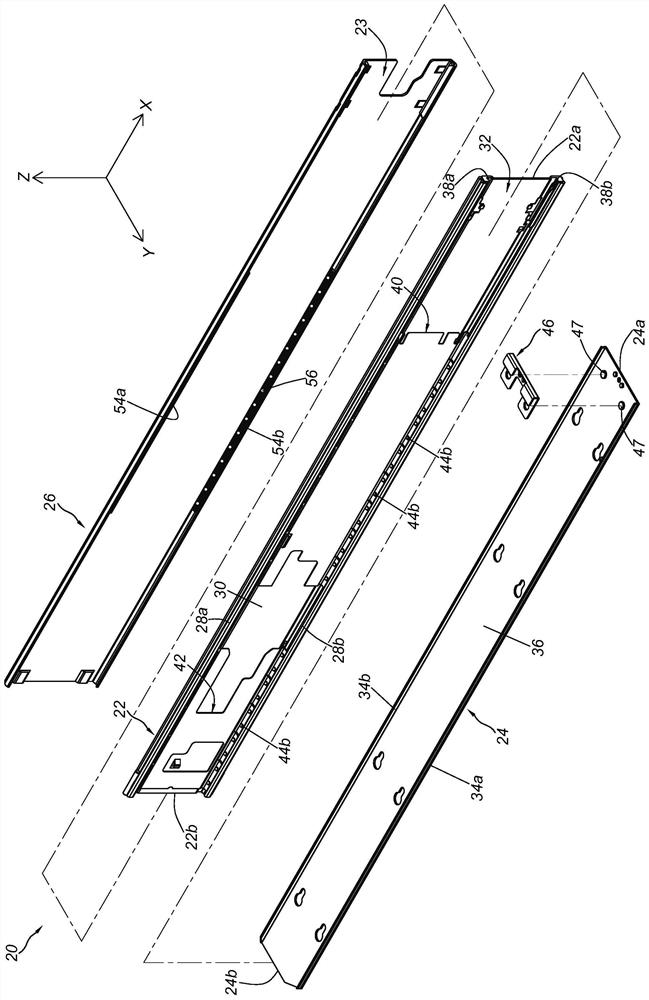

[0022] Such as figure 2 and image 3 As shown, a sliding rail assembly 20 according to the embodiment of the present invention includes a first rail 22 and a second rail 24 . Preferably, a third rail 26 is further included, and the first rail 22 is movably installed between the third rail 26 and the second rail 24 . The first rail 22, the second rail 24, and the third rail 26 are longitudinally displaceable relative to each other. It is worth mentioning that in this embodiment, the X-axis direction is the longitudinal direction (or the length direction of the slide rail), the Y-axis direction is the transverse direction (or the lateral direction of the slide rail), and the Z-axis direction is the vertical direction (or the slide rail direction). height direction).

[0023] The first rail 22 is movably mounted on a channel 23 of the third rail 26 . The first rail 22 has a first end portion 22 a and a second end portion 22 b away from the first end portion 22 a of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com