Method for increasing ingredient adding speed of electromagnetic chuck

An electromagnetic sucker and speed technology, which is applied in the field of batching control and electrical control in the foundry industry, can solve the problems of difficult control of the proportion of waiting time, poor charging and demagnetization effects, and low work efficiency, and achieve the effect of shortening the invalid waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

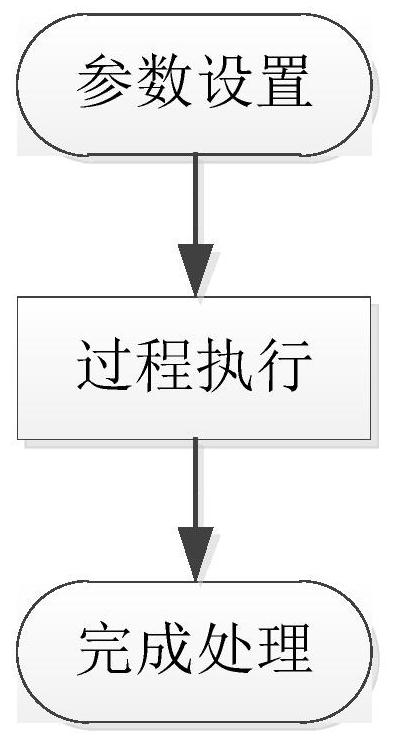

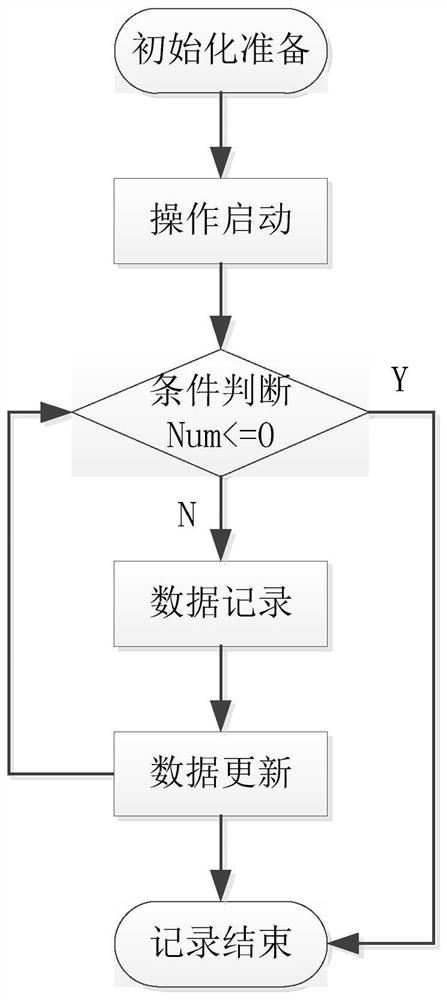

[0041] Such as figure 1 As shown, the method of speeding up the feeding speed of the electromagnetic chuck includes:

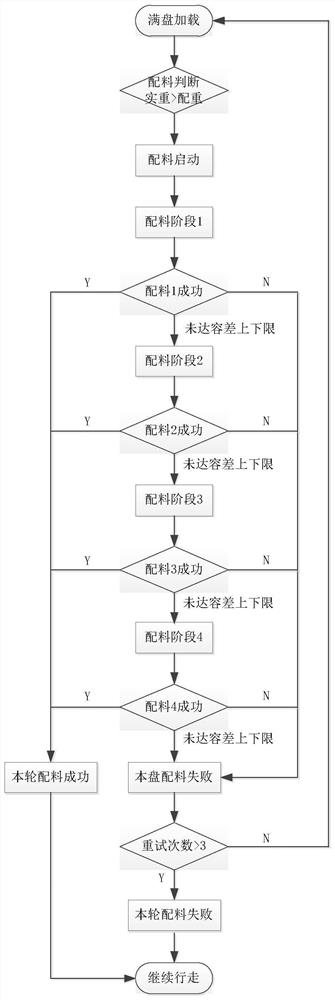

[0042] 1) Full disk loading: According to the set batching parameters, the electromagnetic chuck walks to the raw material area, absorbs the raw materials with full excitation voltage, and moves to the safe walking position;

[0043] 2) Batching judgment: If the suction amount of the raw material absorbed by the current tray exceeds the remaining weight and tolerance of the raw material, it will enter the final tray batching. At this time, the batching amount is the remaining weight of the raw material, otherwise the normal full tray is filled ;

[0044] 3) The last plate ingredient: load the variable used to control the amount of material absorbed by the electromagnetic chuck, and set the state of the electromagnetic chuck to Busy (1) in the task, and use the variable of the amount of material absorbed by the electromagnetic chuck to control and adjust the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com