Device and method for measuring foam size distribution

A size distribution and foam technology, applied in the field of foam testing devices, can solve the problems of testing affecting foam diameter distribution, difficulty in extracting foam images, blurring of foam images, etc. The effect of image size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

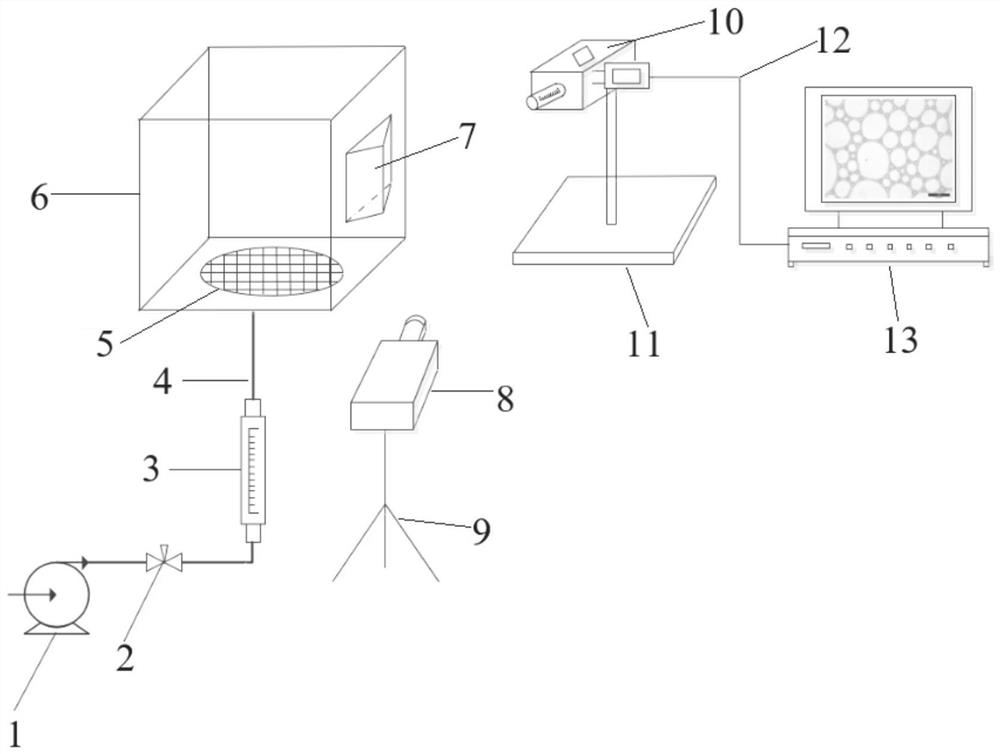

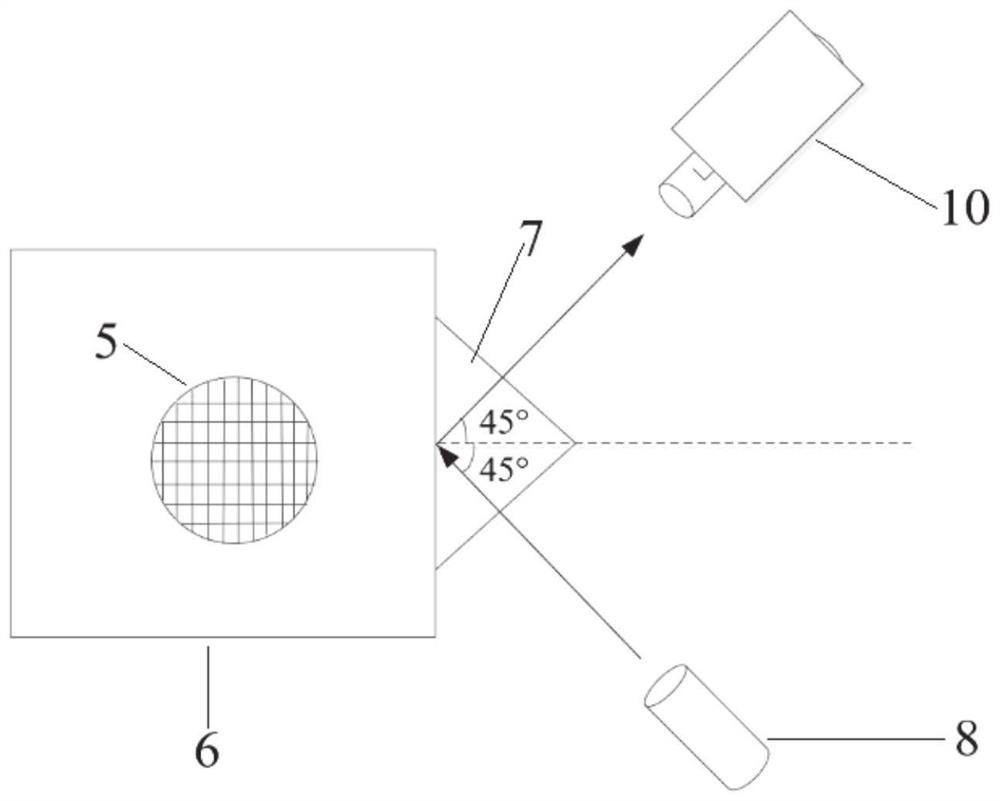

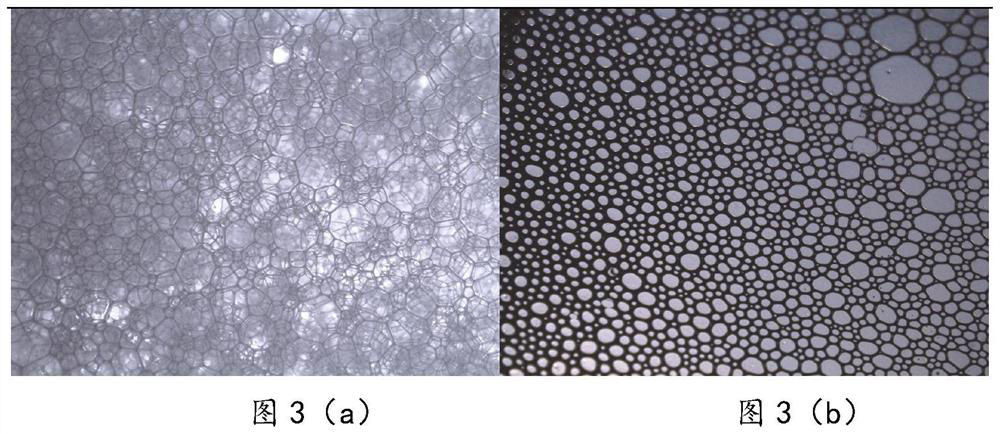

[0039] In a typical embodiment of the present invention, such as Figure 1-Figure 2 As shown, a device for measuring the size distribution of foam is proposed, including a foaming unit for generating foam, a foam collection unit for collecting foam, an optical path conversion unit for light conversion, and an optical imaging unit for optical imaging. An imaging unit and an image acquisition unit.

[0040] Wherein, the lower end of the bubble collection unit is connected to the foaming unit, the optical path conversion unit is arranged on the side of the bubble collection unit, the optical imaging unit is arranged on one side of the optical path conversion unit, and the image acquisition unit is connected to the optical imaging unit.

[0041] Specifically, this embodiment adopts the bubbling method, and the foaming unit is composed of a gas pump 1, a gas phase valve 2, a gas flow meter 3, an air guide tube 4 and an air stone plate 5, and the gas pump 1 passes through the air gu...

Embodiment 2

[0061] In another typical embodiment of the present application, the method for measuring the device for measuring foam size distribution as described in Example 1 is provided, and the specific process is as follows:

[0062] Step 1: Connect the gas pump 1, the gas phase valve 2, and the gas flow meter 3 to the bottom of the gas stone plate 5 through the air guide tube 4;

[0063] Step 2: Pour the configured foam liquid into the transparent glass box 6 from the top, open the gas pump 1 and the gas phase valve 2, control the gas flow, and after a certain height of foam is generated in the transparent glass box 6, turn off the gas pump 1 and the gas phase valve 2. Gas phase valve 2;

[0064] Step 3: Fix the right-angled prism 7 on the surface of the transparent glass box 6, align the fill light 8 with the left side of the right-angled prism 7 along the horizontal 45°, align the lens of the microscope 10 with the right side of the right-angled prism 7 along the horizontal 45°, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com