A multi-well two-phase flow metering skid and its metering method

A metering method and technology of metering skids, which are applied in the direction of testing/calibrating volume flow, volume/mass flow generated by mechanical effects, and detecting dynamic effects of fluid flow, etc., which can solve the problem that the separator occupies a large area and cannot produce a single well. Real-time dynamic monitoring and other issues to achieve the effect of reducing labor costs, reducing inspection and maintenance costs, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

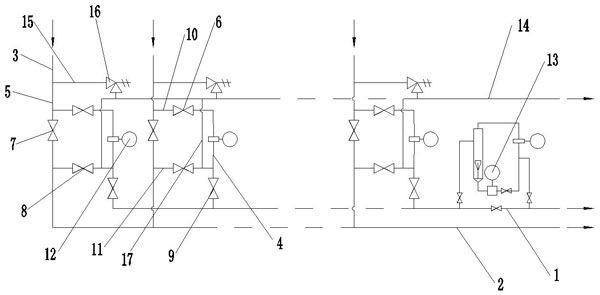

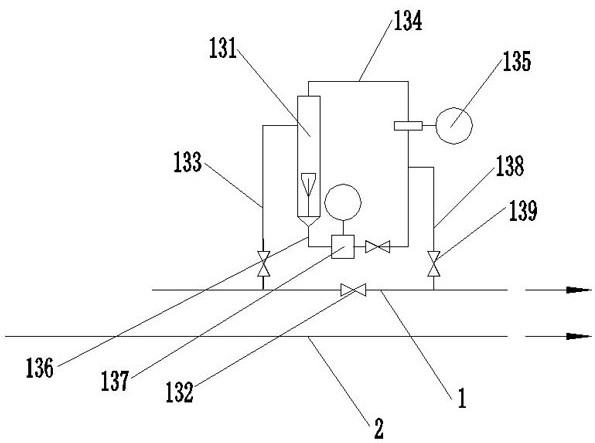

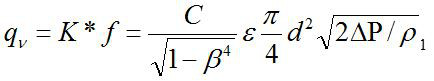

[0057] Such as figure 1 and figure 2 As shown, a multi-well two-phase flow metering skid includes a first production pipeline 1, a second production pipeline 2 and several wellhead connecting pipelines 3 respectively connected to the wellhead, and each of the wellhead connecting pipelines 3 are all communicated with the second production pipeline 2 through the second production connection pipeline 5, each of the second production connection pipelines 5 is provided with a second control valve 7, and each of the second production connection pipelines 5 is respectively provided with a first transition pipeline 10 and a second transition pipeline 11 communicating with the second production connection pipeline 5 from one end close to the wellhead connection pipeline 3 to one end far away from the wellhead connection pipeline 3. A transition line 10 and a second transition line 11 are connected to the second production connection line 5 respectively at both ends of the second cont...

Embodiment 2

[0061] Such as figure 1 and figure 2 As shown, on the basis of the above-mentioned embodiments, a pressure relief pipeline 14 is also included, and the several wellhead connecting pipelines 3 communicate with the pressure relief pipeline 14 through the first pressure relief connecting pipeline 15 .

[0062] In order to ensure the safety of the pipeline, the metering skid is also equipped with a pressure relief pipeline 14, and each wellhead connection pipeline 3 is connected to the pressure relief pipeline 14 through the first pressure relief connection pipeline 15. When the fluid pressure is too large, it can be Perform pressure relief.

Embodiment 3

[0064] Such as figure 1 and figure 2 As shown, on the basis of the above embodiments, each of the pressure relief pipelines 14 is provided with a safety valve 16 .

[0065] A safety valve 16 is provided to automatically open and release pressure when the fluid pressure is too high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com