Small-sized mobile loading vehicle on rail

A rail and vehicle-carrying technology, which is applied to railway car body components, railway vehicle shape measuring devices, railway auxiliary equipment, etc., can solve the problems of high cost and large mobile loading car body, and achieve cost reduction, easy installation and transportation, The effect of changing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

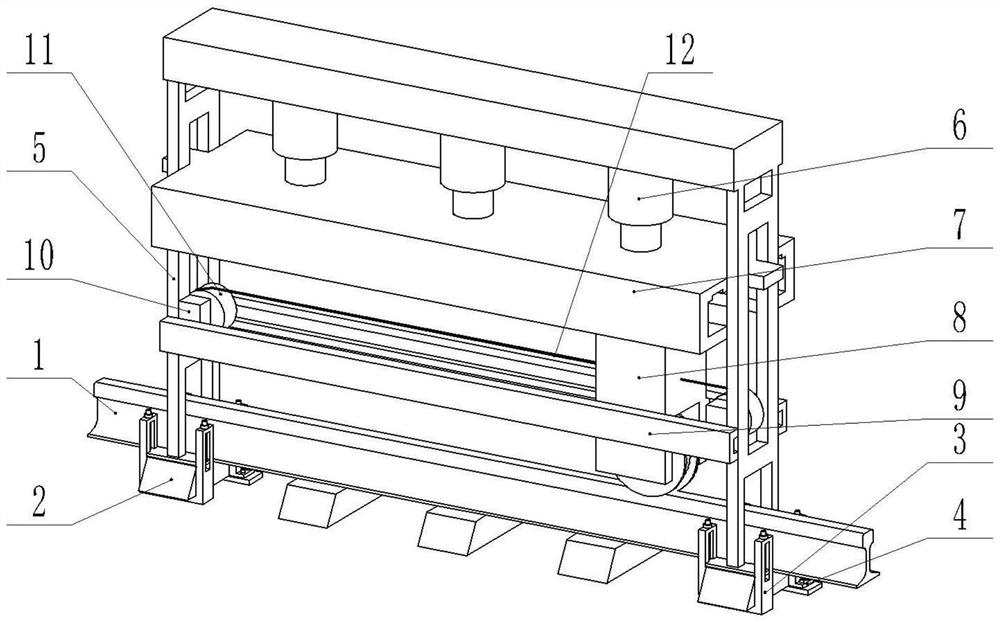

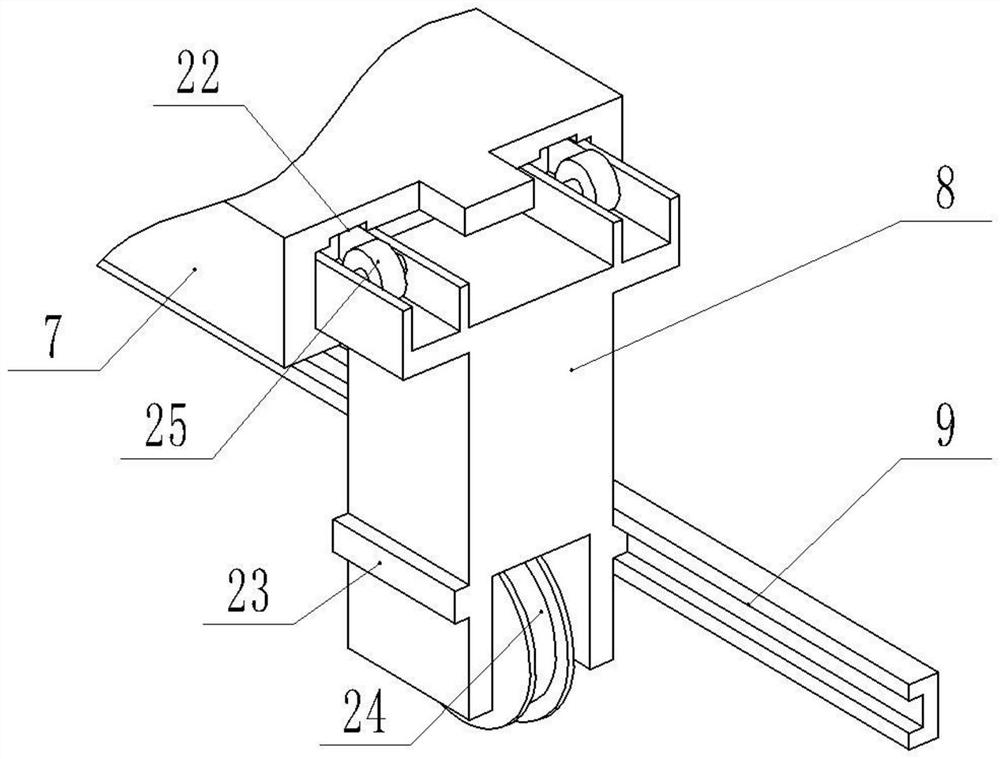

[0024] A small rail 1 mobile loading car, such as Figure 1-Figure 5 As shown, it includes frame 5, hydraulic device 6, up track 7 and wheel simulator 8.

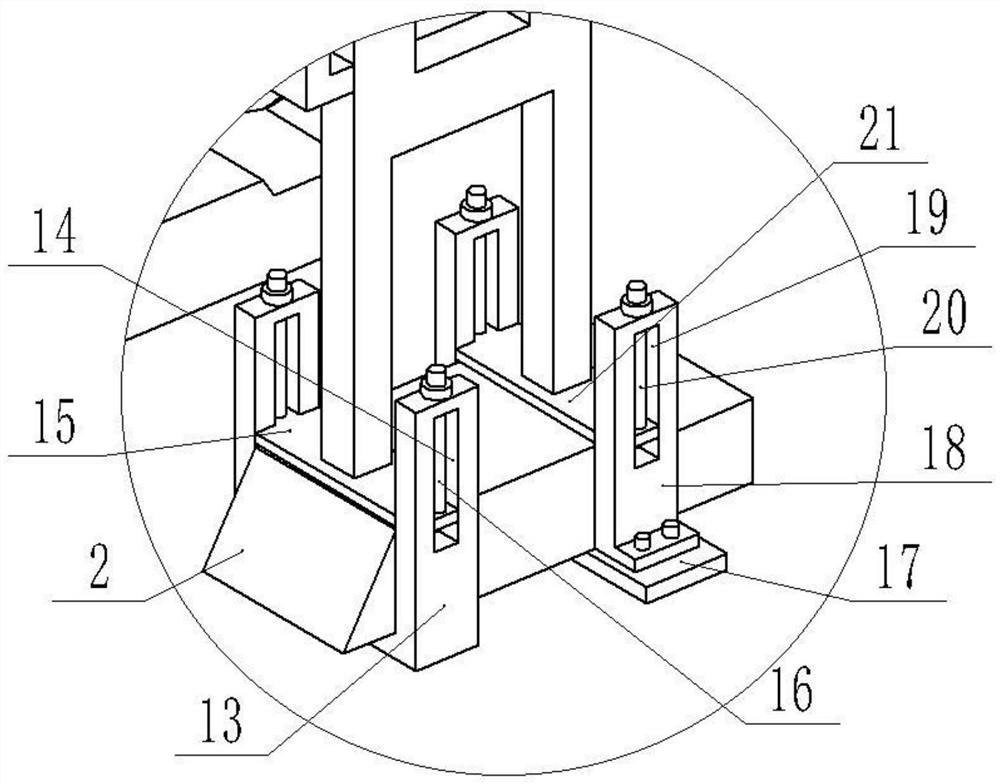

[0025] The frame 5 is in the shape of a gantry frame as a whole, and the frame 5 has two ends in total, and the two ends are respectively concrete two vertical frame bodies 27, and adopt a horizontal frame body 28 to connect between the vertical frame bodies 27. The bottom of the vertical frame body 27 is fixedly provided with an outer fixed foot 3 and an inner fixed foot 4, the outer fixed foot 3 includes a U-shaped first base 13 and a first fixed plate 15, and the upper end of the first base 13 is provided with a first slide Slot 14, the upper end of the first chute 14 is provided with a first screw hole, the first screw hole is threaded with a first fixing stud 16, and the two ends of the first fixing plate 15 are slidably arranged on the two first chute 14 Among them, the first fixing stud 16 can abut against the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com