High-speed plow body curved surface parameterization design method based on horizontal straight element line method

A parametric design, plough body surface technology, applied in the field of agricultural machinery, can solve the problems of cumbersome guide curve formation process, reduce the design efficiency of the plough body, etc., to achieve the effect of improving design efficiency, reducing design time, and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

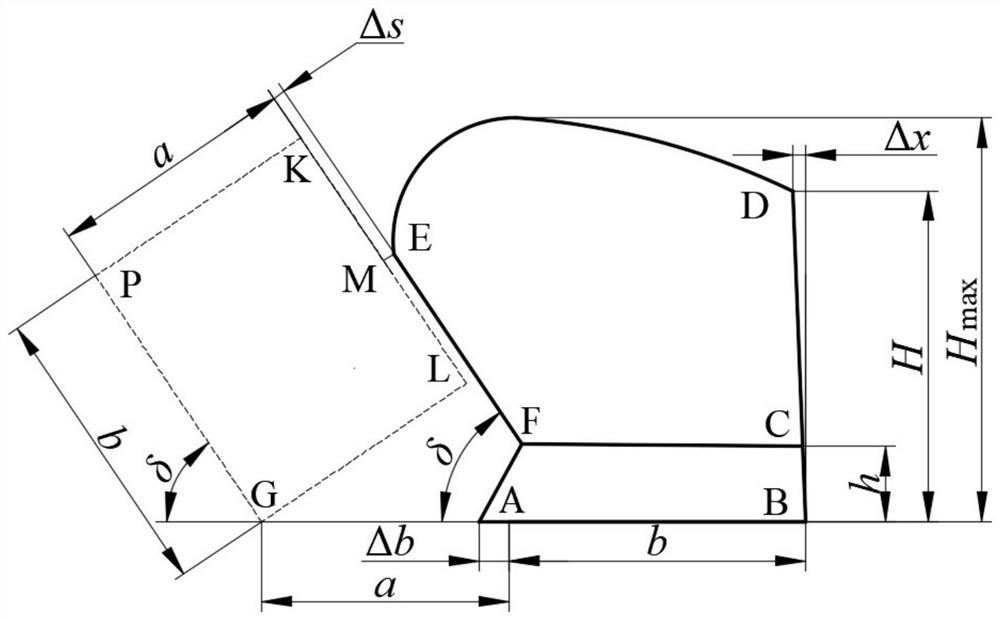

[0156] The plow body surface of the high-speed plow is designed with the plowing depth a=350mm and the plowing width b=420mm.

[0157] Based on the plowing depth and plowing width of the plow body surface of the high-speed plow, the parameters of the plow body surface of this type of high-speed plow are calculated, as shown in Table 2 and Table 3.

[0158] Table 2 Surface parameters of high-speed plow body

[0159]

[0160]

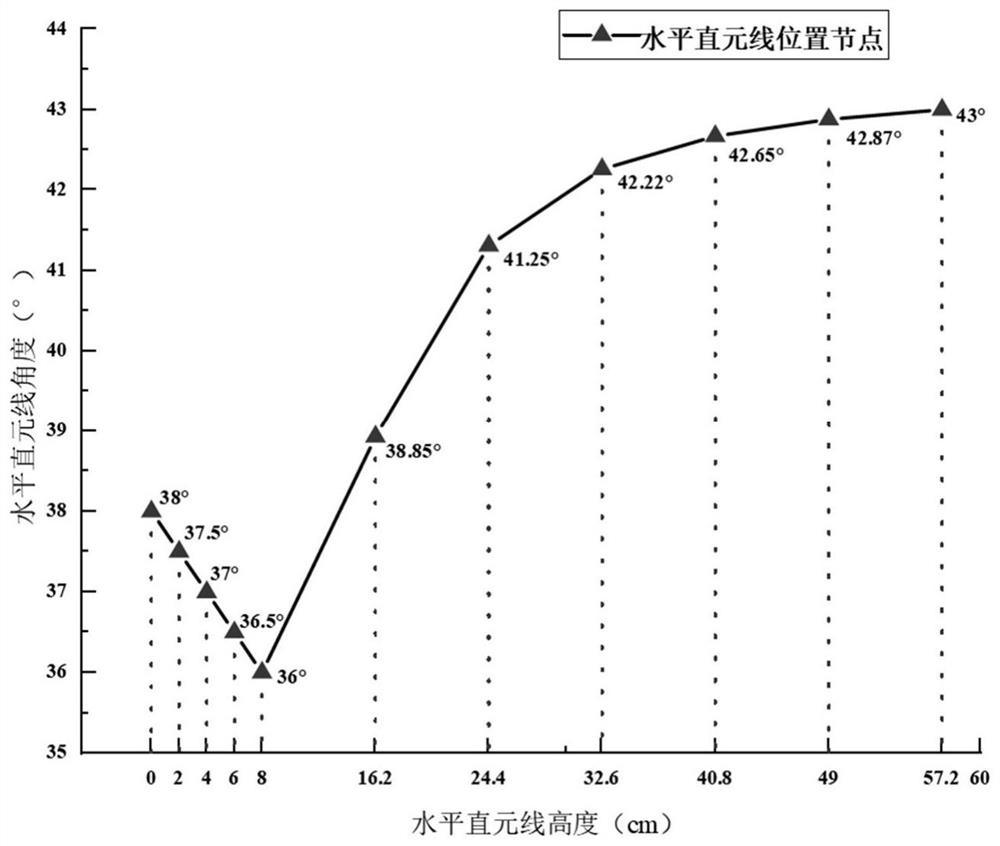

[0161] Table 3 Corresponding angles of straight element lines at different heights of the guide curve

[0162]

[0163] Draw the data in Table 3 into a diagram of the change law of element line angle, the result is as follows image 3 shown.

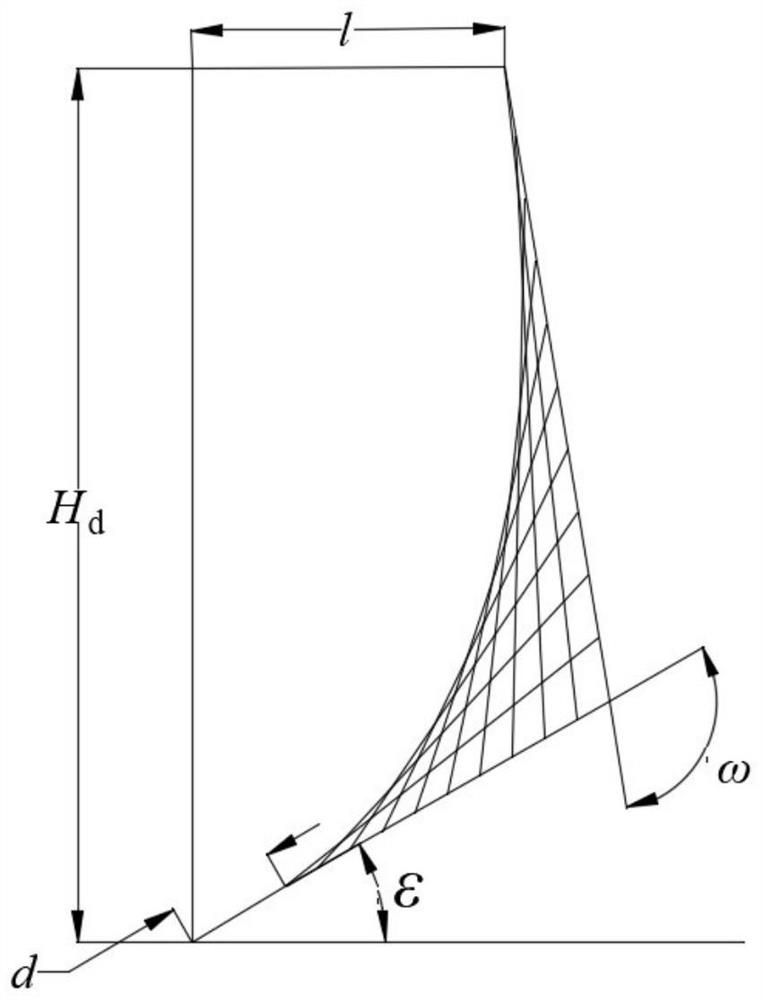

[0164] In conjunction with each parameter of high-speed plow plow body curved surface in table 2 and table 3, utilize three-dimensional software to draw the concrete steps of high-speed plow plow body curved surface as follows: (note utilizes above-mentioned parameter to utilize any three-dimensional desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com