Auxiliary support for fire-fighting assembly assembling and assembling method thereof

A technology of auxiliary brackets and components, applied in fire rescue and other directions, can solve the problems of many operation steps, bending over or squatting down, inconvenient use, etc., to avoid contact with the ground, reduce operation steps, and reduce moisture erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

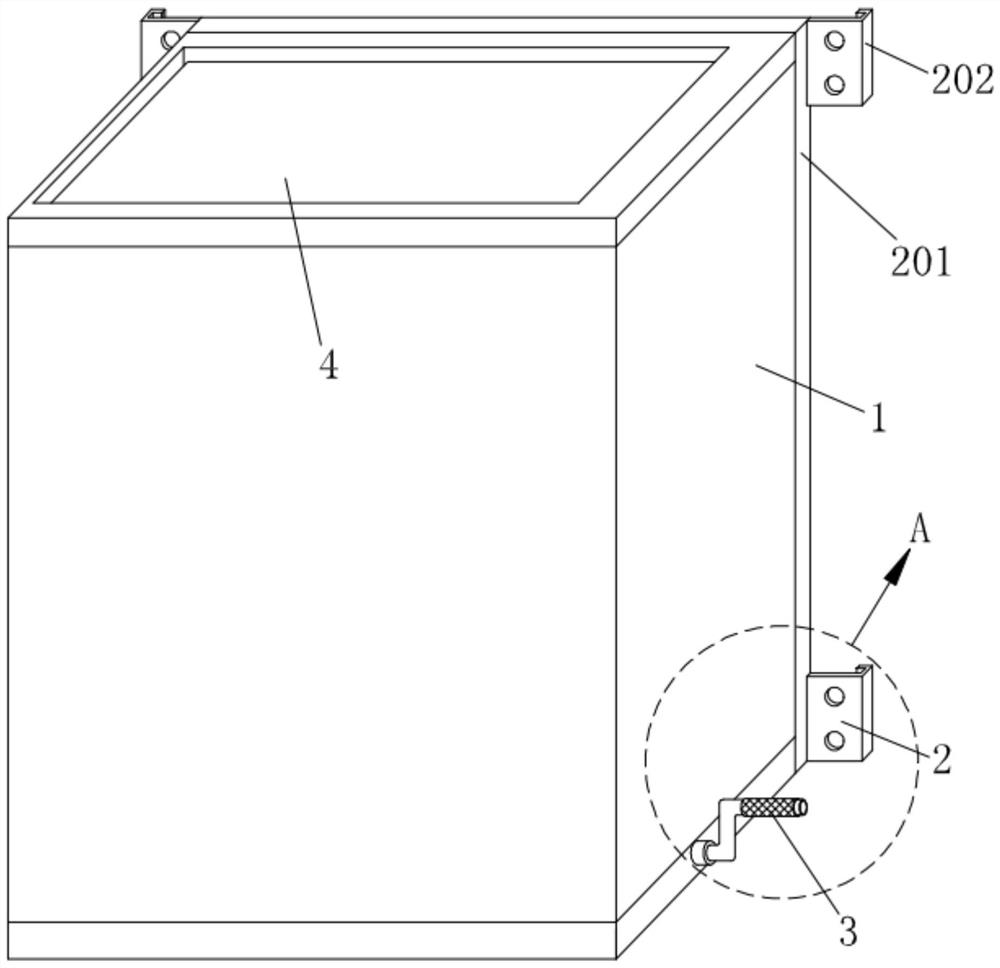

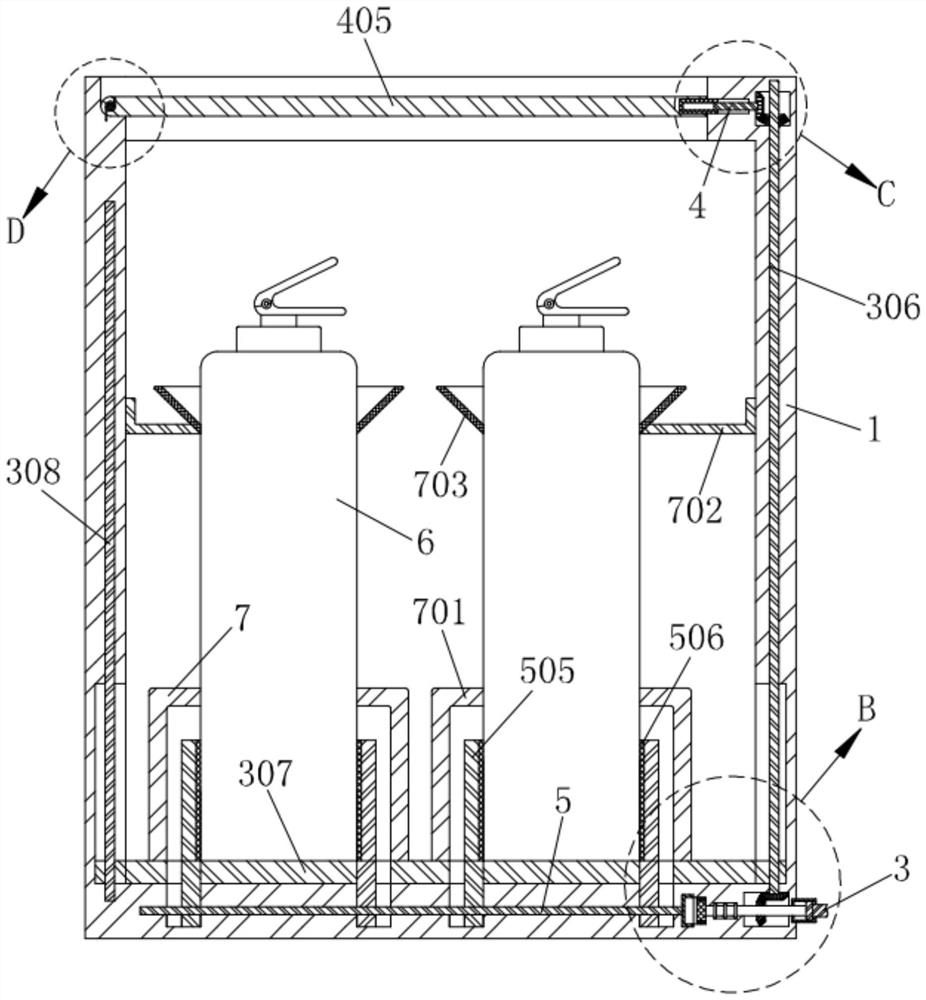

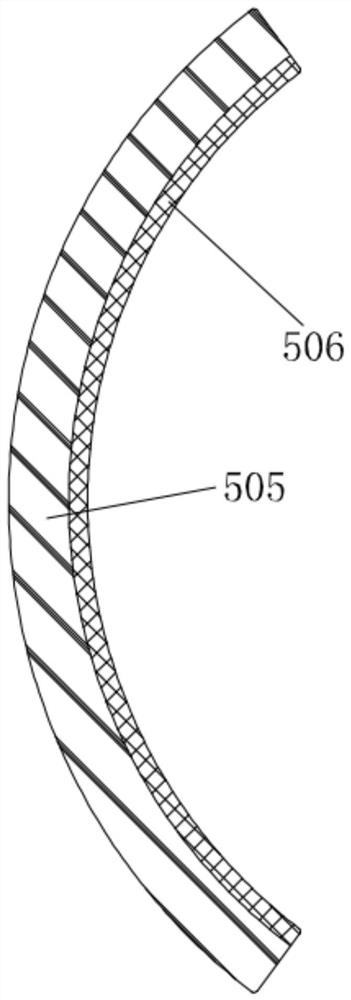

[0031] Such as Figure 1-Figure 8 As shown, an auxiliary bracket for assembly of a fire-fighting component according to the present invention includes a frame body 1, and the frame body 1 is provided with a mounting mechanism 2, and the frame body 1 is provided with an adjustment mechanism 3, and the frame body 1 is provided with an opening and closing mechanism 4, the frame body 1 is provided with a limit mechanism 5, the adjustment mechanism 3 is provided with a fire extinguisher body 6, and the frame body 1 is provided with a guide mechanism 7;

[0032] The adjustment mechanism 3 includes a handle 302, the frame body 1 is provided with a handle 302, the handle 302 is fixedly connected with a connecting rod 303, and the connecting rod 303 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com