Transfer device for carrying, boxing and stacking production line

A technology of transfer device and stacking production line, which is applied in the field of transfer device in the handling and packing and palletizing production line, which can solve the problems of complicated operation and no weight index detection of packing goods, so as to achieve the effect of ensuring quality and facilitating palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

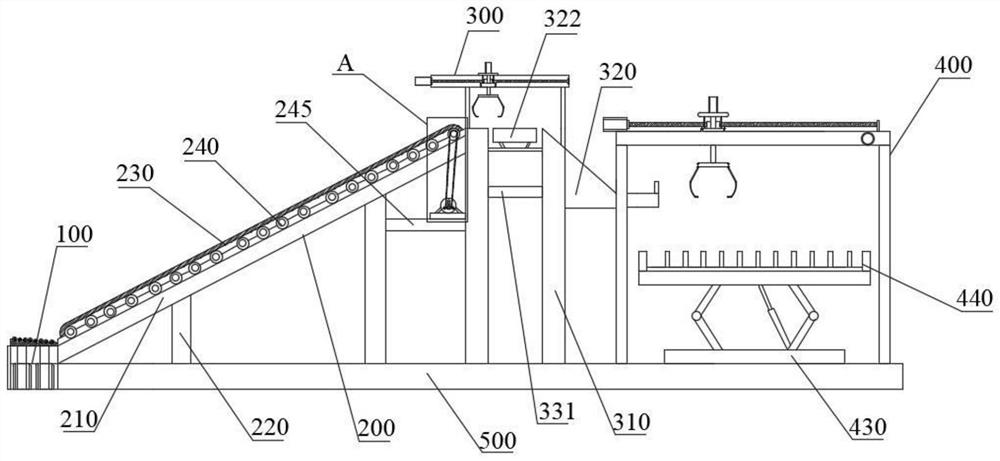

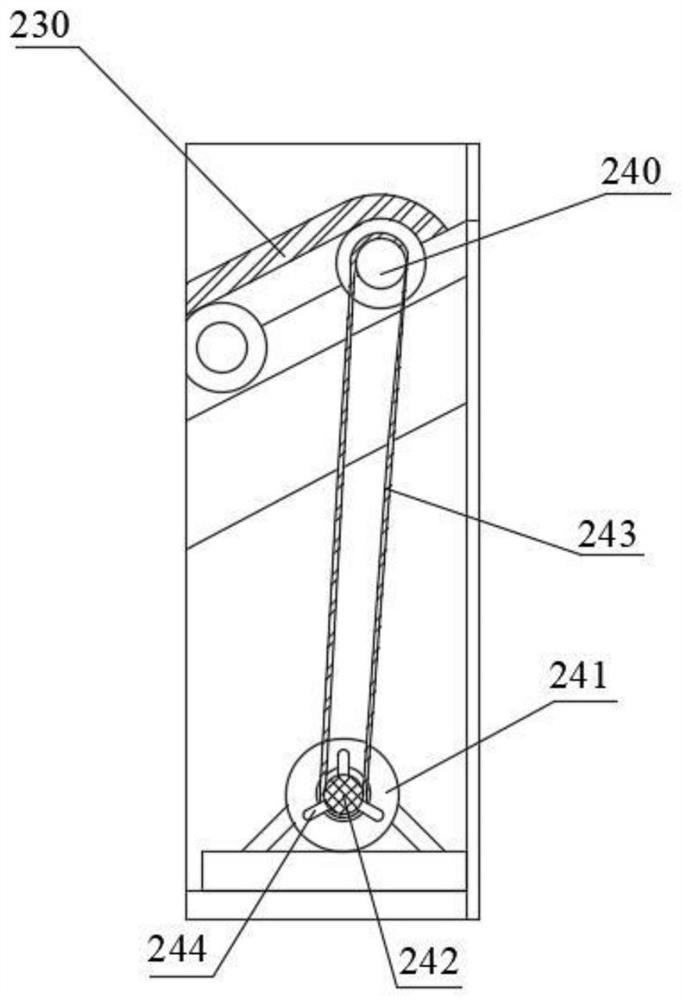

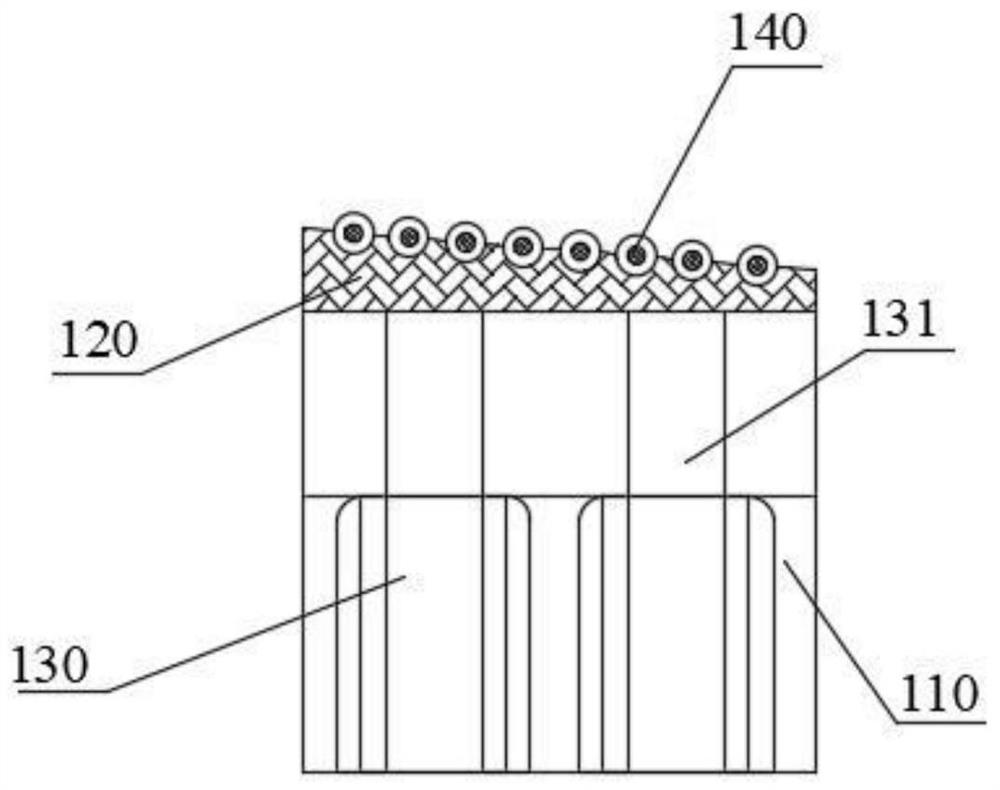

[0032] Such as figure 1As shown, this embodiment provides a transfer device for handling the packing and palletizing production line, including a jacking and feeding mechanism 100, a lifting and conveying mechanism 200, and a transfer weighing mechanism 300 arranged in sequence from one side to the other. , the transfer and palletizing mechanism 400 , the lifting and conveying mechanism 200 , the transfer and weighing mechanism 300 and the transfer and palletizing mechanism 400 are all arranged on the base 500 . The jacking and feeding mechanism 100 is used to lift the packed goods onto the lifting conveying mechanism 200; the lifting conveying mechanism 200 is used to lift and transport the packed goods to the transfer weighing mechanism 300; After the boxed goods are weighed and tested, the boxed goods with unqualified weight are removed, and the boxed goods with qualified weight are transferred to the transfer palletizing mechanism 400; the transfer palletizing mechanism 40...

Embodiment 2

[0039] Such as figure 1 , Figure 4-6 As shown, the difference between the transfer device provided in this embodiment and the case-packing and palletizing production line in Embodiment 1 is that the transfer weighing mechanism 300 includes a mounting column 310, a transfer placement mechanism and a weighing mechanism. The column 310 is correspondingly arranged on the side of the support frame 245 , and the transfer placement mechanism and the weighing mechanism are arranged on the installation column 310 . The transfer placement mechanism includes a support column 311, an installation frame 312 and a first motor 313, the two support columns 311 are located on the two installation columns 310, the installation frame 312 is located on the two support columns 311, and the first motor 313 is located on the installation One side of the frame 312, the first motor 313 is connected with the first lead screw 314 extending into the inner cavity of the installation frame 312, the outer...

Embodiment 3

[0046] Such as figure 1 , Figure 7-8 As shown, the difference between the transfer device provided in this embodiment and the first embodiment is that the transfer and palletizing mechanism 400 includes a bottom mounting frame 410, an X-axis mounting frame 411, and a Y-axis mounting frame. 412, two X-axis mounting frames 411 and two Y-axis mounting frames 412 are located above the bottom mounting frame 410, a sliding table 413 is provided between the two X-axis mounting frames 411, and a second sliding table 413 is provided above the sliding table 413 Both sides of the lead screw 414 and the second lead screw 414 are provided with bearing housings 415 connected with the slide table 413 , and one end of the second lead screw 414 is connected with a third motor 416 . A third lead screw 417 passing through the sliding table 413 is arranged between the two Y-axis mounting frames 412 , and a fourth motor 418 is connected to the end of the third lead screw 417 , and the third lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com