Polishing tool

A technology for grinding tools and bottom plates, which is applied in the direction of manufacturing tools, grinding machines, grinding racks, etc., can solve the problems of elevated center of gravity, low service life, easy breakage, etc., to ensure shock resistance and torsion resistance, and complete machine The effect of size reduction and improved control feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be described in detail below in conjunction with the accompanying drawings.

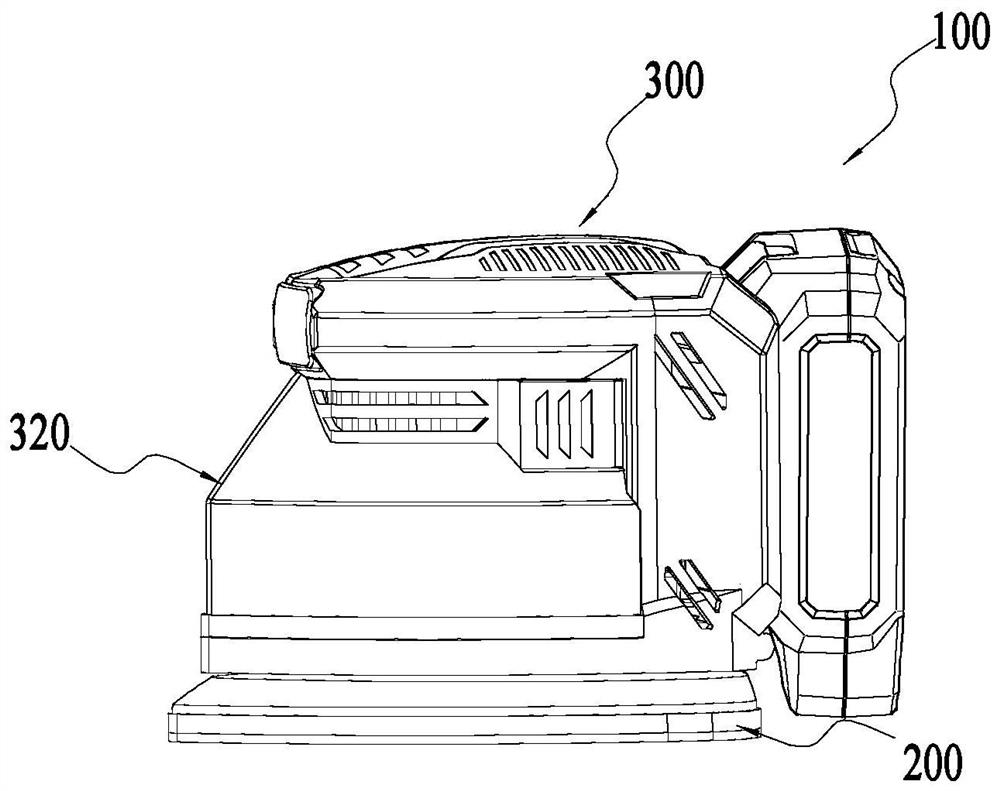

[0093] Such as figure 1 Shown is a grinding tool 100 shown in an embodiment of the present invention. The grinding tool 100 of the embodiment of the present invention is specifically a sander, and more specifically a flat sander that can be held by the user with one or both hands. machine. It can be understood that the grinding tool 100 can be round sand, triangular sand, square sand, special-shaped sand, etc., and only the applicable grinding tools that meet the technical solution of the present invention are within the protection scope of the present invention.

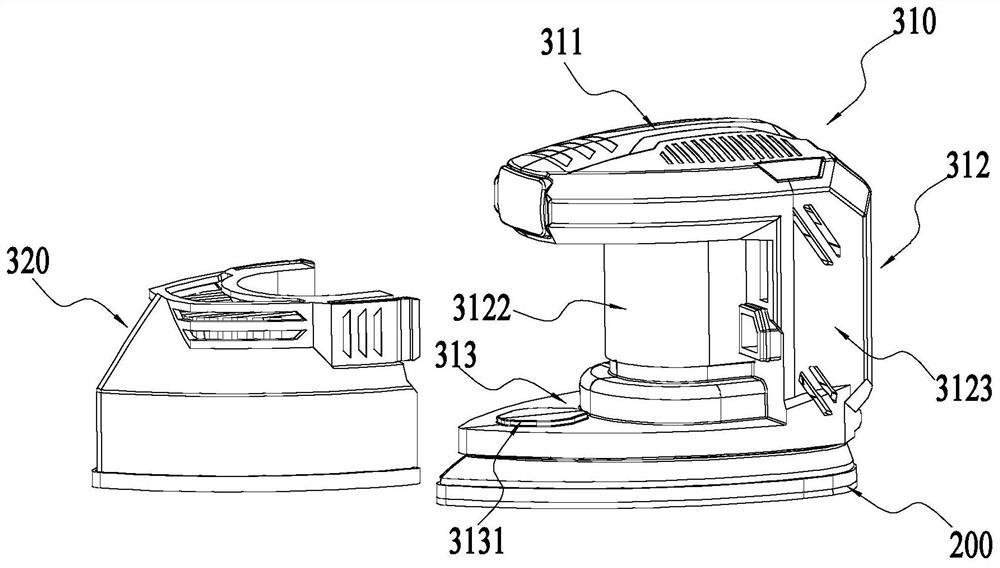

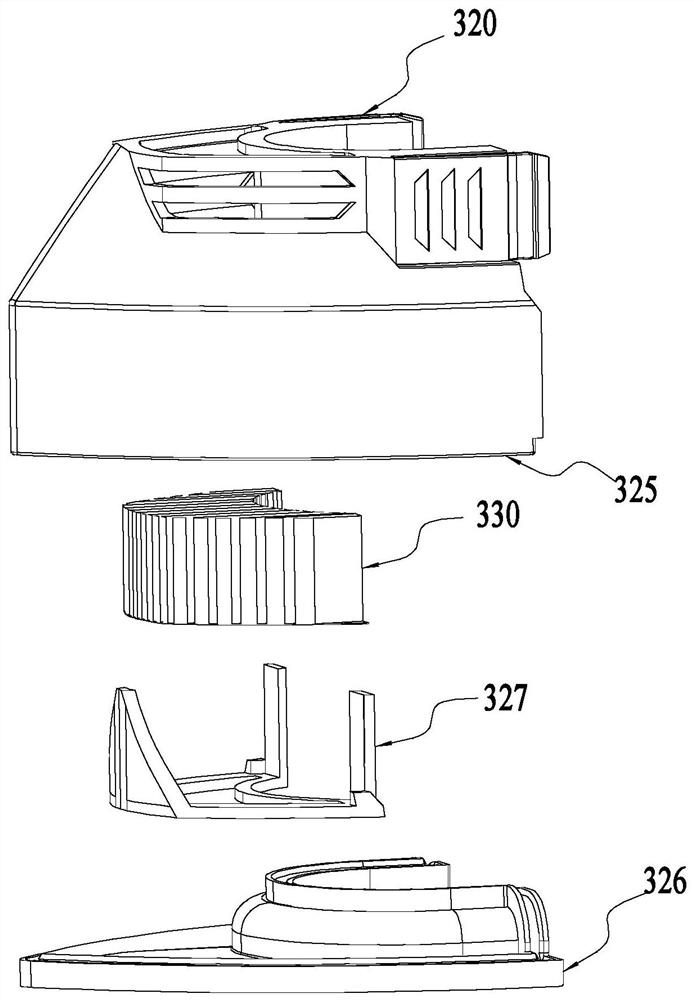

[0094] The grinding tool 100 of the embodiment of the present invention includes a bottom plate assembly 200, a casing assembly 300, a driving mechanism 400, a fan assembly, a dust removal assembly and a power supply. Among them such as figure 2 As shown, the casing assembly includes a body casing 310 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap