Mold with good injection molding effect and anti-overflow device for injection mold

An injection mold and anti-overflow technology, which is applied in the field of injection molds, can solve the problems of material heating, affecting the injection molding effect, and the injection speed does not change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

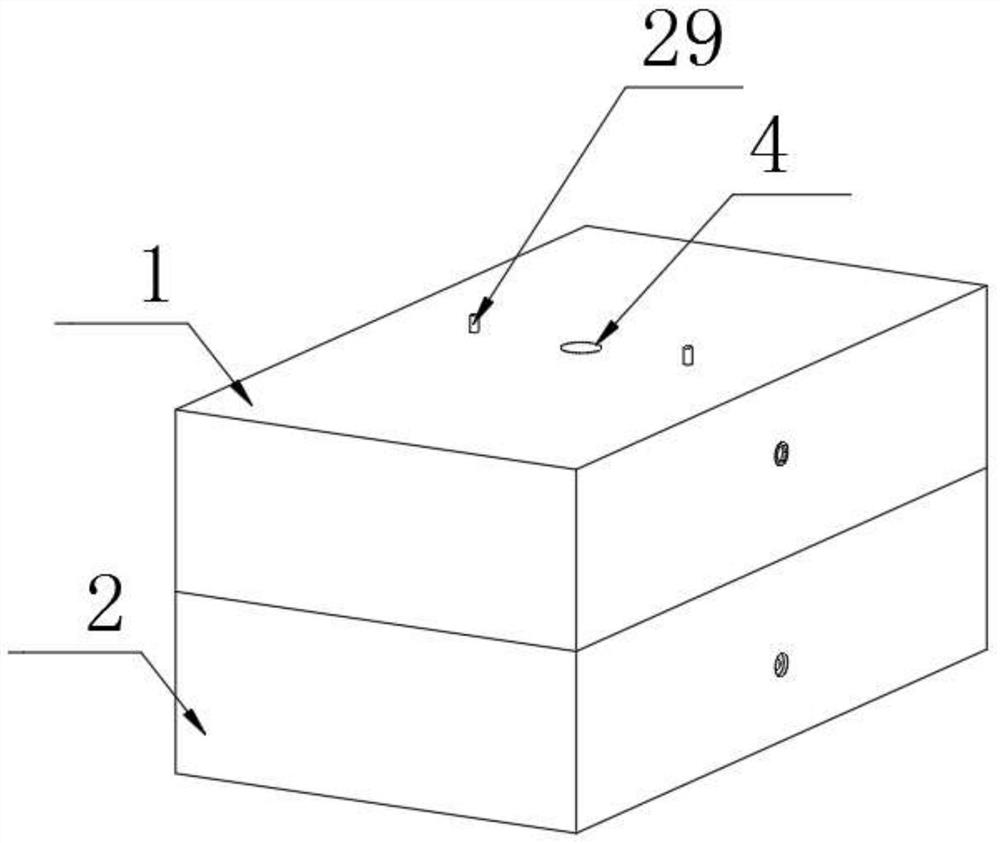

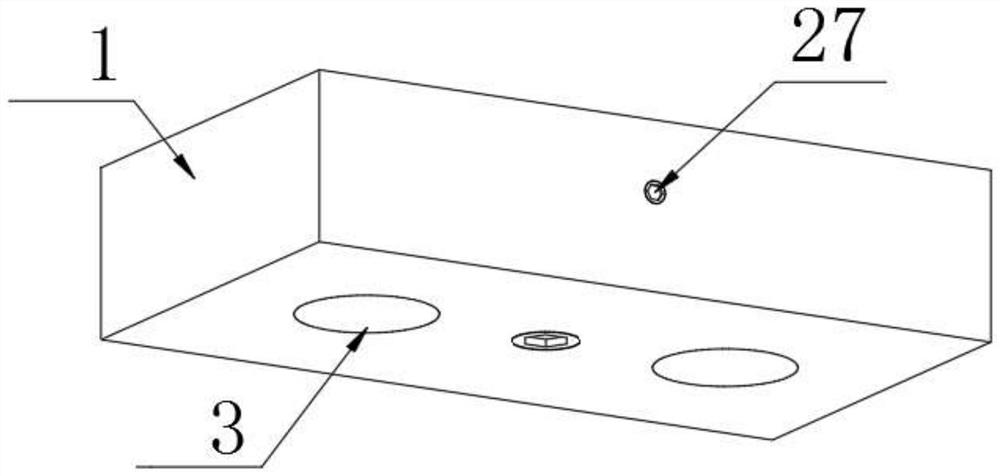

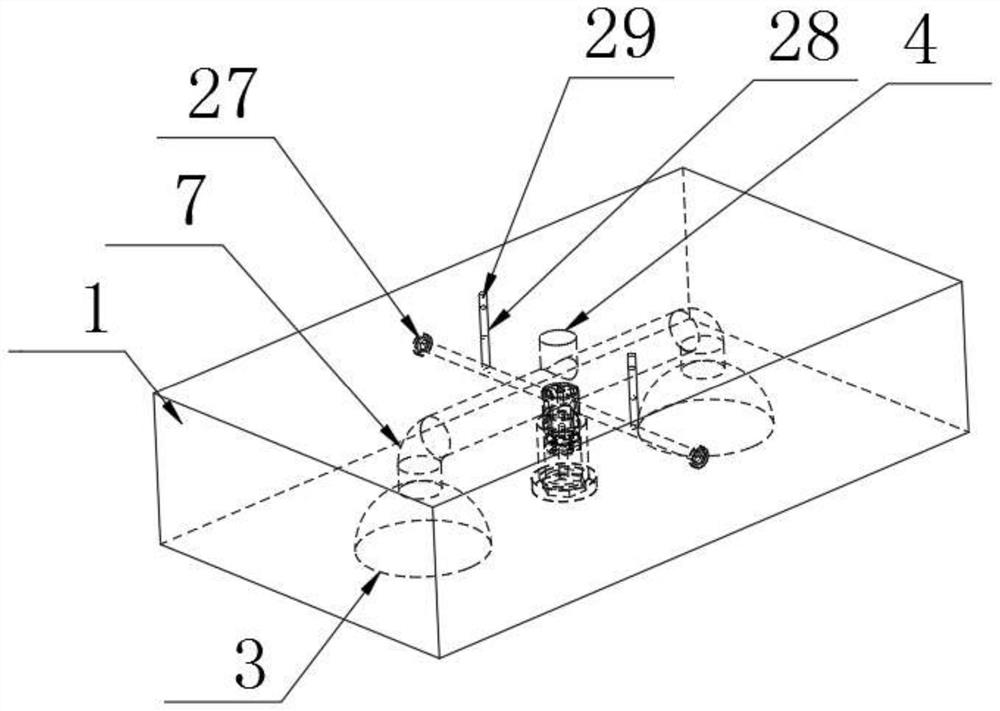

[0038]Embodiment 1, a mold with good injection molding effect, including an upper mold 1 and a lower mold 2, the opposite sides of the upper mold 1 and the lower mold 2 are provided with an injection cavity 3, and also includes the above-mentioned anti-overflow for the injection mold Device 30, the top of the upper mold 1 is provided with a main flow channel 4, the top of the main flow channel 4 is set as an input end 5, the bottom end of the main flow channel 4 is set as an output end 6, and the bottom of the main flow channel 4 is provided with an auxiliary The runner 7 communicates with the secondary runner 7. The secondary runner 7 is arranged on the top of the injection cavity 3 and communicates with the injection cavity 3. The inner walls of the main channel 4 and the secondary runner 7 are inlaid with heating coils 8 , the overflow prevention device 30 for the injection mold is arranged inside the upper mold 1 .

[0039] When in use, the upper mold 1 is driven downward ...

Embodiment 2

[0040] Example 2, such as Figure 1-5 and Figure 9 As shown, the inside of the upper mold 1 is located at the bottom of the secondary channel 7 and is provided with a flow control mechanism that controls the opening size of the output end 6 of the main channel 4. The flow control mechanism is connected to the heating coil 8 on the inner wall of the secondary channel 7, thereby passing The heat of the secondary channel 7 causes the flow control mechanism to expand with heat and contract with cold, and then adjust the opening size of the output end 6 of the main channel 4 to adjust the flow rate of the material entering the secondary channel 7 through the main channel 4, thereby adjusting the flow rate of the material in the secondary channel. 7 The internal flow rate, when the temperature is high, the intersecting part of the flow control mechanism and the main channel 4 is smaller, so that the output end 6 of the main channel 4 has a larger opening, and the material flows fas...

Embodiment 3

[0041] Example 3, such as Figure 2-4 and Figure 6-11 As shown, the flow control mechanism includes a first accommodating chamber 9 and a second accommodating chamber 10, the first accommodating chamber 9 is arranged at the bottom of the second accommodating chamber 10, the first accommodating chamber 9 and the second accommodating chamber Support rods 11 are fixedly connected between the chambers 10, a partition 12 is provided on the top of the first storage chamber 9, and a through groove 13 is provided on the partition 12, and a port 14 is provided on the first storage cavity 9. The top of the accommodation chamber 9 is provided with a sealing cloth 15, the sealing cloth 15 is made of rubber material, the sealing cloth 15 is arranged at the port 14, and a support plate 16 is arranged between the sealing cloth 15 and the partition plate 12, and the support plate 16 and The inner wall of the first storage chamber 9 is fixedly connected, and the center of the sealing cloth 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com