Concrete aggregate containing high-titanium blast furnace slag and preparation method thereof

A concrete aggregate and blast furnace slag technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor performance of concrete aggregate, achieve poor performance and improve crack resistance And compressive performance, improve the effect of compressive capacity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

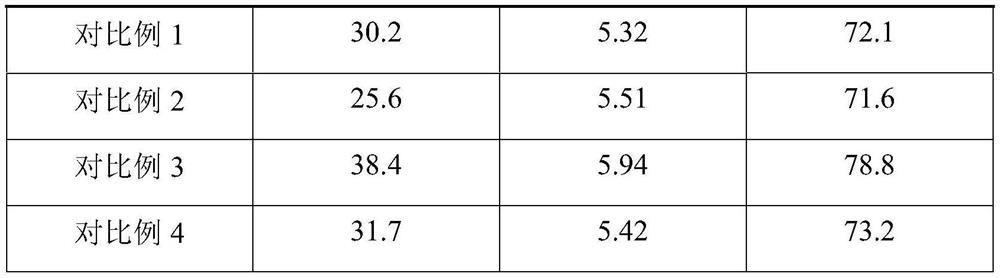

Examples

Embodiment 1

[0022] A concrete aggregate containing high titanium type blast furnace slag comprises the following components in parts by weight: 100 parts of high titanium type blast furnace slag aggregate, 50 parts of recycled concrete aggregate, 10 parts of modified straw fiber and 20 parts of seaweed fiber.

[0023] Among them, the high-titanium blast furnace slag aggregate is prepared by the following method: slowly cooling the high-titanium blast furnace slag, removing iron, crushing to less than 40mm, and then secondary crushing to less than 20mm, and then undergoing plasticity and sieving in turn to obtain Aggregate with a particle size of 5-15mm is the high-titanium blast furnace slag aggregate.

[0024] Concrete recycled aggregates are prepared by the following method: crush waste concrete, ball mill, screen out aggregates with a particle size of 5-15 mm, and then soak them in water and 10 wt% hydrochloric acid solution for 5 hours, take them out and wash them in medium Dry at 40°...

Embodiment 2

[0028] A concrete aggregate containing high titanium blast furnace slag comprises the following components in parts by weight: 300 parts of high titanium blast furnace slag, 180 parts of recycled concrete aggregate, 13 parts of modified straw fiber and 25 parts of seaweed fiber.

[0029] Among them, the high-titanium blast furnace slag aggregate is prepared by the following method: slowly cooling the high-titanium blast furnace slag, removing iron, crushing to less than 40mm, and then secondary crushing to less than 20mm, and then undergoing plasticity and sieving in turn to obtain Aggregate with a particle size of 5-15mm is the high-titanium blast furnace slag aggregate.

[0030] Concrete recycled aggregate is prepared by the following method: the waste concrete is crushed and then ball-milled, the aggregate with a particle size of 5-15mm is screened out, and then soaked in water and 13wt% hydrochloric acid solution for 6 hours, taken out and washed with water until medium Dr...

Embodiment 3

[0034] A concrete aggregate containing high titanium blast furnace slag comprises the following components in parts by weight: 500 parts of high titanium blast furnace slag aggregate, 300 parts of recycled concrete aggregate, 15 parts of modified straw fiber and 30 parts of seaweed fiber.

[0035] Among them, the high-titanium blast furnace slag aggregate is prepared by the following method: slowly cooling the high-titanium blast furnace slag, removing iron, crushing to less than 40mm, and then secondary crushing to less than 20mm, and then undergoing plasticity and sieving in turn to obtain Aggregate with a particle size of 5-15mm is the high-titanium blast furnace slag aggregate.

[0036] Concrete recycled aggregates are prepared by the following method: crush waste concrete and ball mill, screen out aggregates with a particle size of 5-15mm, then soak them in water and 15wt% hydrochloric acid solution for 7 hours, take them out and wash them in medium Dry at 50°C, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap