Method for fixing curtain wall keel on I-shaped steel web

A fixing method and technology of I-beam, applied in the direction of wall, building material processing, building components, etc., can solve problems such as disadvantage, the main keel of the curtain wall cannot be installed normally, affecting the project schedule and construction period, etc., and achieve the effect of simple and practical process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

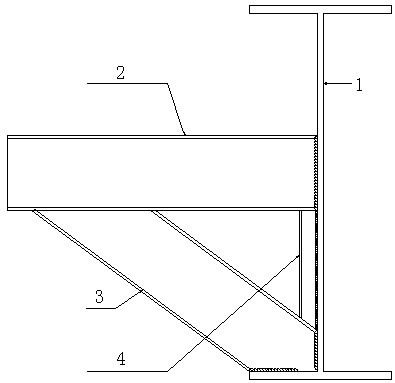

[0016] Such as figure 1 Shown: A method for fixing the curtain wall keel on the I-shaped steel web. When the I-beam or H-shaped steel is used at the position where the main keel of the curtain wall takes root, there is no external sealing plate method, which leads to the failure of the normal installation of the main keel of the curtain wall and affects the project. The schedule and construction period are especially suitable for the section form where the main keel of the curtain wall is rooted with I-beam or H-beam.

[0017] It is a treatment method to take remedial measures by taking advantage of the lack of the outer sealing plate of the I-beam or H-beam that has been installed, resulting in the inability to install the curtain wall column, and affecting the project schedule.

[0018] To remedy the missing side sealing plate of the I-beam or H-beam that has been installed, first calculate the web and curtain wall rear rooting cantilever corbels and reinforced connectors, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com