Steel stair

A technology of stairs and steel plates, which is applied to stairs, ladder-like structures, and pedals, can solve the problems of complex manufacturing process, difficulty in popularizing steel stairs, and thick plates, so as to reduce material costs, facilitate popularization and use, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

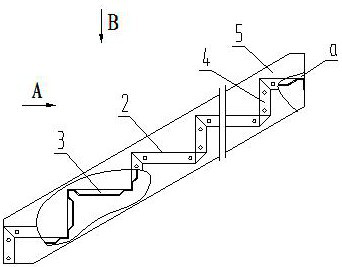

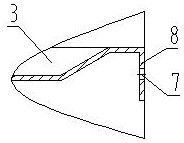

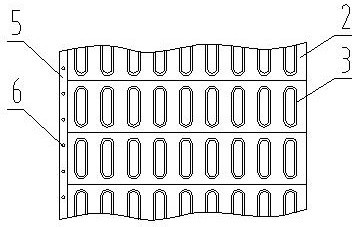

[0025] Such as figure 1 As shown, the present invention is a steel staircase, which consists of steps 2 with a set of regular grooves 3, and the function of the grooves is to increase the rigidity of the steel plate. The length direction of the regular groove 3 is perpendicular to the width direction of the step 2, which can transmit the force applied on the step to the vertical board. The side end of the step 2 has a side sealing plate 4 which can make the side end of the step smooth and increase rigidity at the same time.

Embodiment 2

[0027] For the steel staircase described in embodiment 1, the length of the regular groove 3 is 50-400mm, the width of the regular groove 3 is 15-100mm, and the depth of the regular groove 3 is The fruit is best placed within the range of 2-50mm.

Embodiment 3

[0029] Embodiment 1 or 2 or the steel staircase described above, the thickness of the step 2 is 1.2-4.0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com