Supporting and locking device and supporting equipment of cantilever type lifting stage

A technology of locking device and supporting equipment, which is applied in the field of stage machinery, can solve problems such as sudden drop of stage body, small space, heavy mechanism weight, etc., to eliminate the possibility of overturning, apply to a wide range of sites, and improve work safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

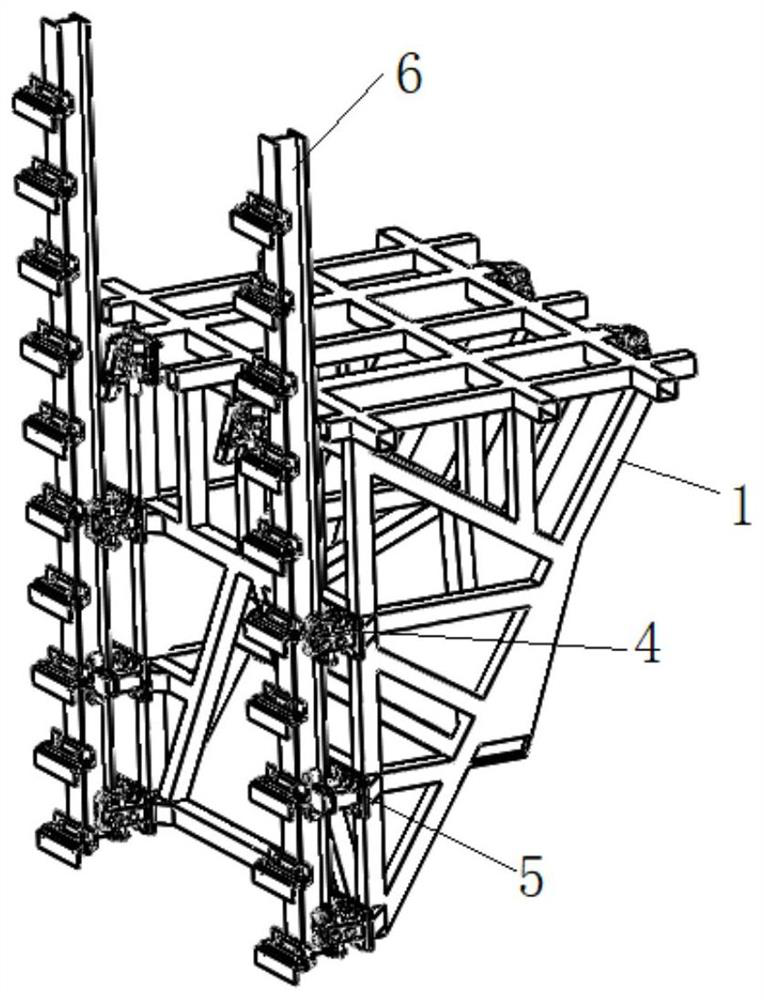

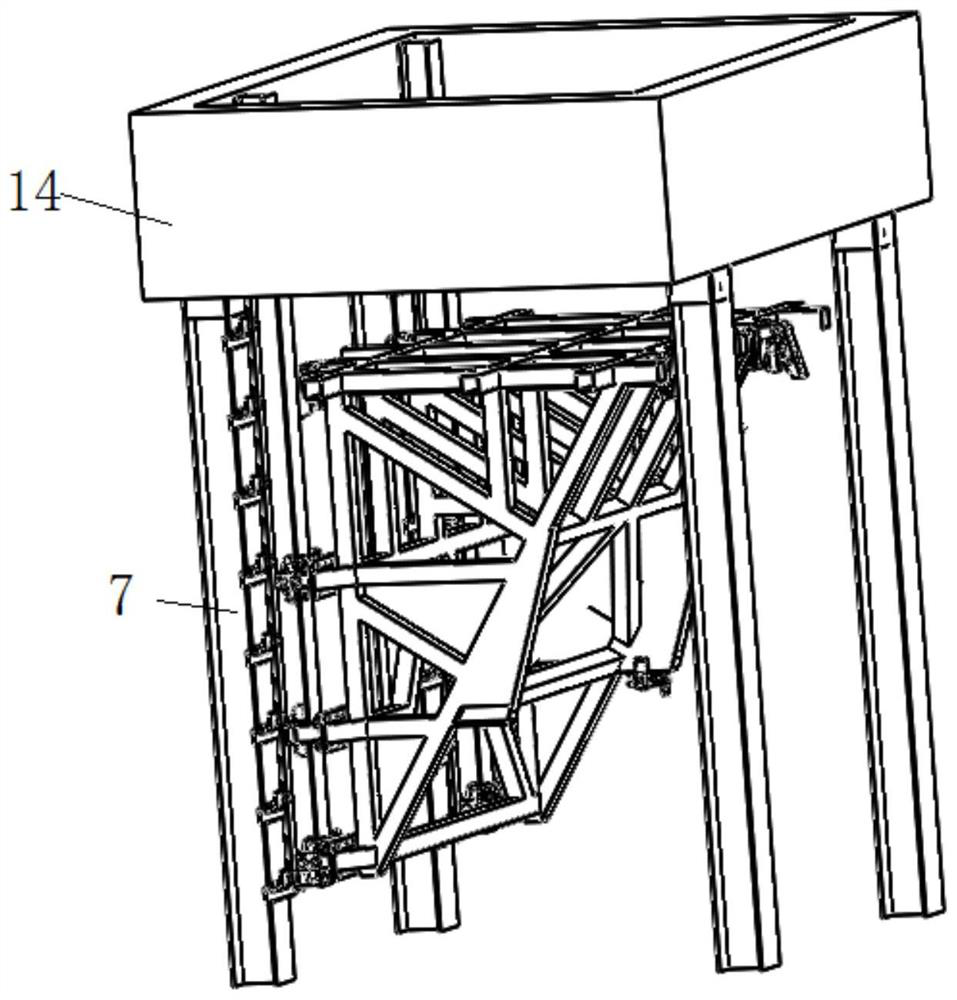

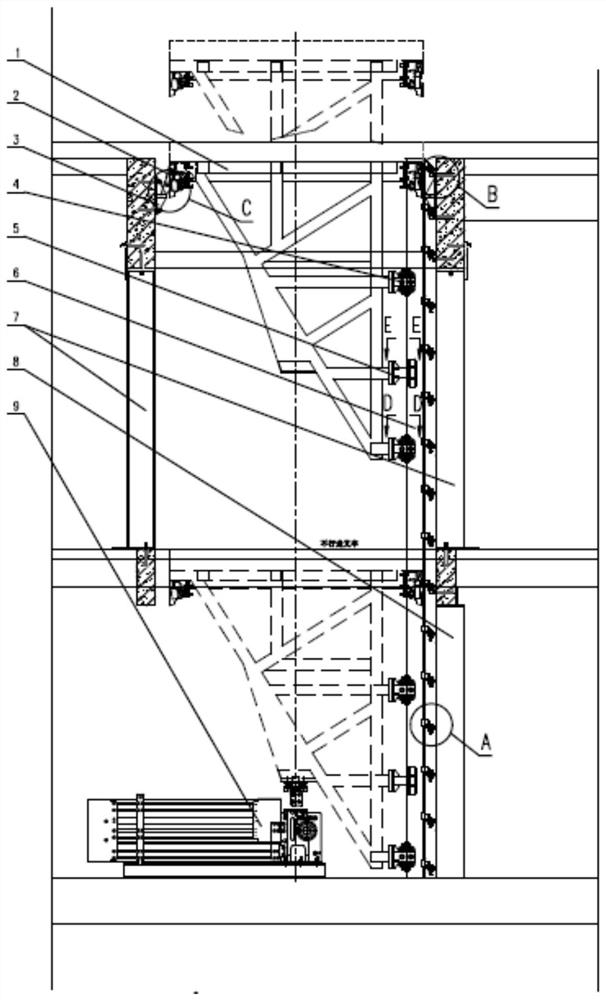

[0082] Such as Figure 1a As shown, it is a partial perspective view of a cantilever lifting stage with a structural support locking device of the present invention, as Figure 1b Shown is a perspective view of the upper part of the structure of the upper steel column of the lifting stage, as shown in Figure 2a, Figure 2b Shown are respectively the front view and the left view of the cantilever lifting stage with the support locking device of the present invention, as image 3 As shown, it is a structural schematic diagram of another structural support locking device of the present invention, as Figure 4 - Figure 8 respectively Figure 2a , Figure 2b Enlarged view of parts A-E in .

[0083] Among them, the support locking device of the cantilever lifting stage of the present invention includes: multiple pairs of movable outrigger mechanisms installed around the body of the cantilever lifting stage; multiple pairs of support seats installed around the building structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com