Valve stress releasing method

A stress release and stress technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as poor pertinence, long time-consuming valve stress, uneven force on equipment, etc., to achieve rapid stress concentration, improve maintenance efficiency, and maintain The effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

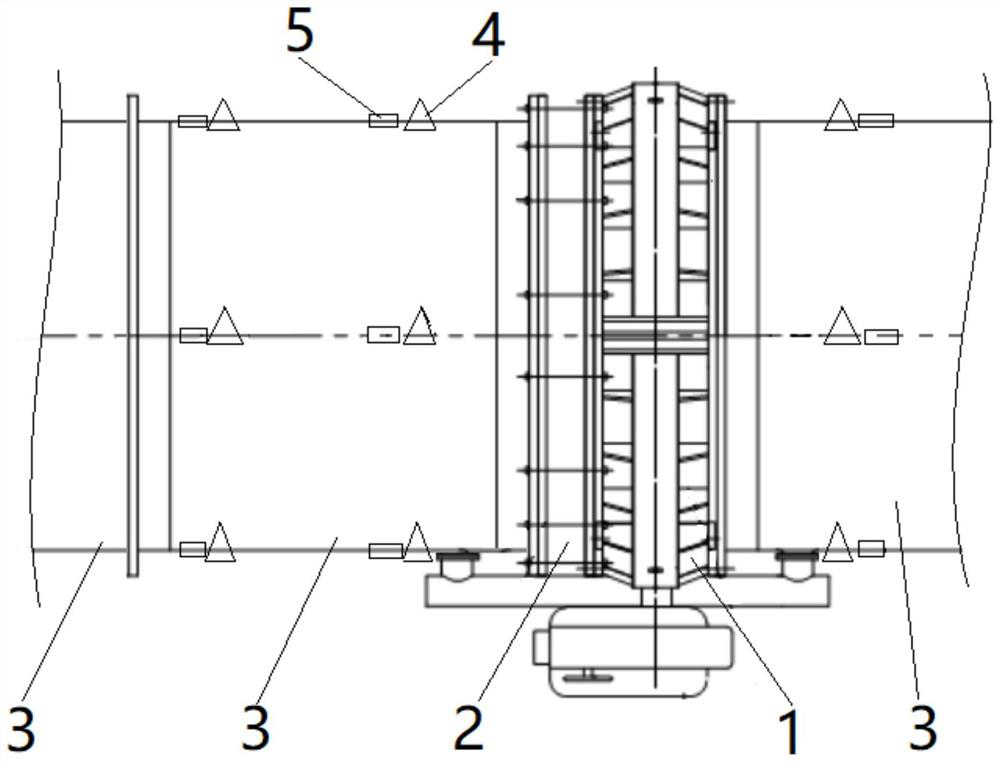

[0033] The delivery pipeline provided in this embodiment, such as figure 1 As shown, it includes: a valve 1, a force transmission expansion joint 2 and a plurality of pipe sections 3; one end of the valve 1 is connected to the force transmission expansion joint 2, and the other end is connected to a pipe section 3. A pipe section 3 is connected to the interface of the force expansion joint 2 away from the end of the valve 1; the other end of the pipe section 3 connected to the force transmission expansion joint 2 is connected to a plurality of pipe sections 3 in sequence, and the pipe section 3 connected to the valve 1 A plurality of pipe sections 3 are sequentially connected at the other end of the pipe section 3 .

Embodiment 2

[0035] The method for releasing the stress of the valve 1 provided in this embodiment includes the following steps:

[0036] S1: Detect the concentricity and coaxiality of the conveying pipeline, analyze the deformation trend of the conveying pipeline, and use the area with the largest deformation tendency as the initial stress release operation area.

[0037] The specific steps of detection and analysis of concentricity and coaxiality are as follows:

[0038] a. The conveying pipeline is arranged with four measuring lines in the axial direction, and the four measuring lines are all located on the outer circumference of the conveying pipeline, and the azimuth angle between two adjacent measuring lines is 90°; on the same measuring line, the conveying pipeline There are at least two measuring points 4 on each part.

[0039] b. Take the leftmost pipe section 3 of the conveying pipeline as the starting end, and take the axis of the pipe section 3 as the reference axis; use the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com