Maintainable cooling equipment for LED car lamp machining

A technology of LED car lights and cooling equipment, which is applied in lighting and heating equipment, coolers, household refrigeration devices, etc. It can solve the problems of single cooling direction, inconvenient adjustment and use, and inconvenient adjustment and use at the entrance, so as to facilitate disassembly, replacement and maintenance , increase the effect of direction and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

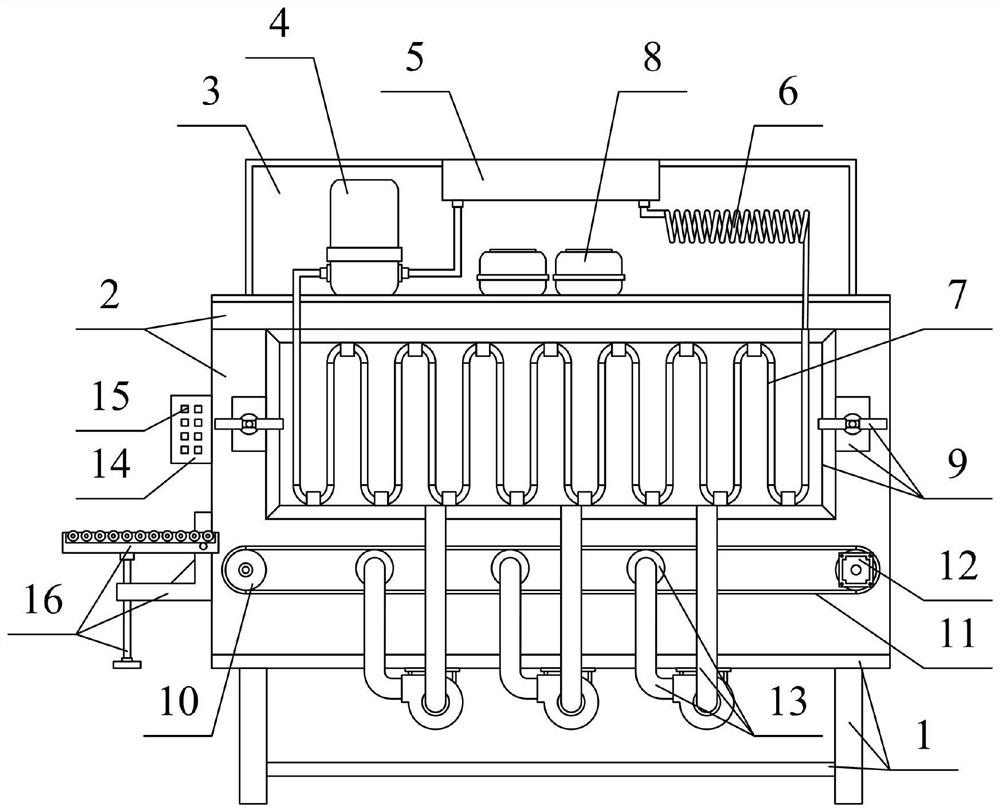

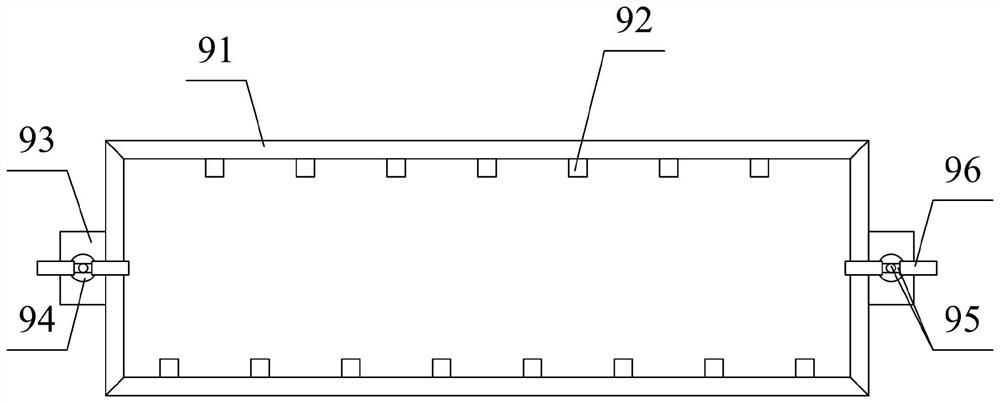

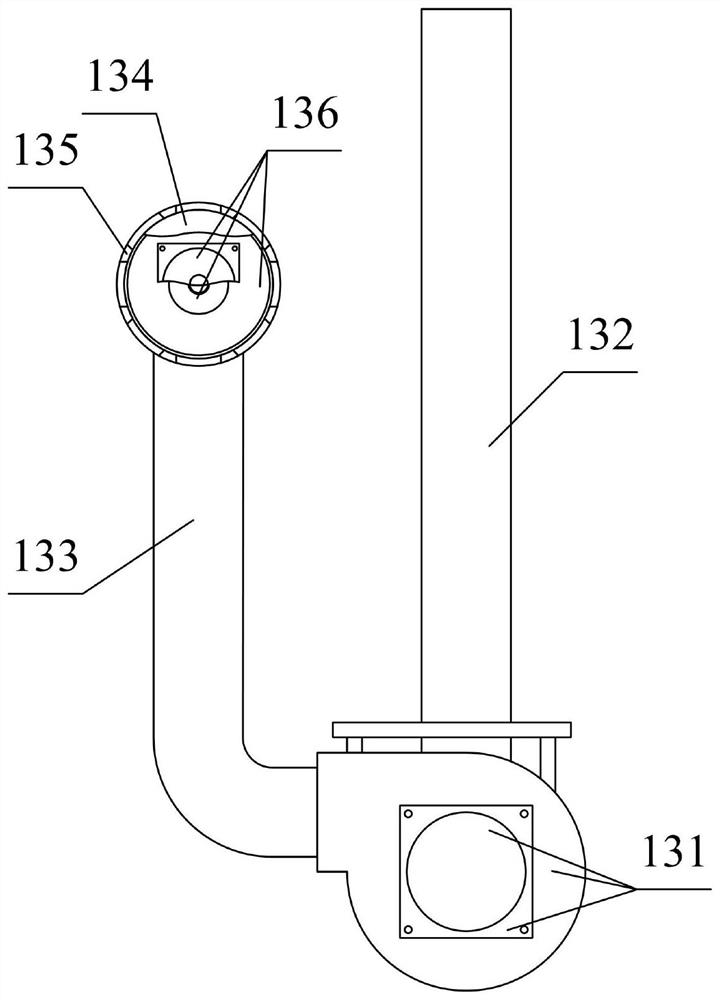

[0038] as attached figure 1As shown, a maintainable cooling device for LED car lamp processing includes a support table 1, a support frame 2, a disassembly cover 3, a compressor 4, a condenser 5, a capillary tube 6, an evaporator 7, a blower fan 8, The movable adjustment frame structure 9, the supporting steel cylinder 10, the conveying mesh belt 11, the conveying motor 12, the wind guide supporting cylinder structure 13, the controller 14, the driving switch 15 and the adjusting feed plate structure 16, the upper end of the support platform 1 The front and rear two bolts are installed with the support frame 2; the bolts of the disassembly cover 3 are installed on the outer side of the upper end of the support frame 2; the bolts of the compressor 4 are installed on the left side of the upper surface of the support frame 2; The condenser 5 bolts are installed in the middle part of the upper side of the disassembly cover 3; one end of the condenser 5 is connected to the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com