Stamping car door zero-surface-difference B column section and top section structure

A section and door technology, which is applied to the top section structure and the zero-surface difference B-pillar section of the stamped car door, can solve the problems of increasing the drag coefficient of the whole vehicle, complicated manufacturing process, and unsightly appearance, and achieves a reduction in the difficulty factor of process realization, Low sliding resistance and light weight effect of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

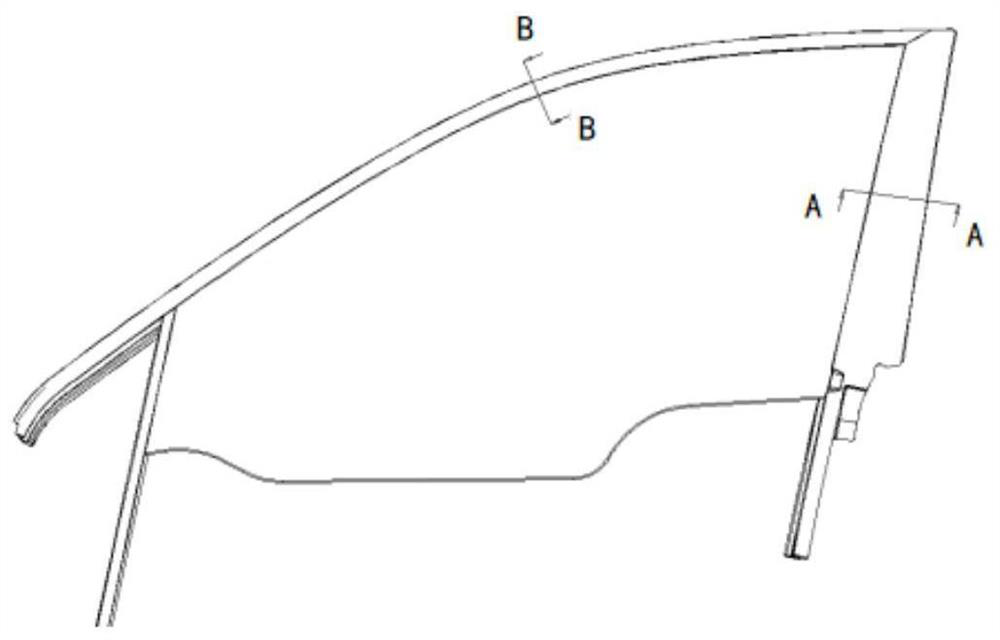

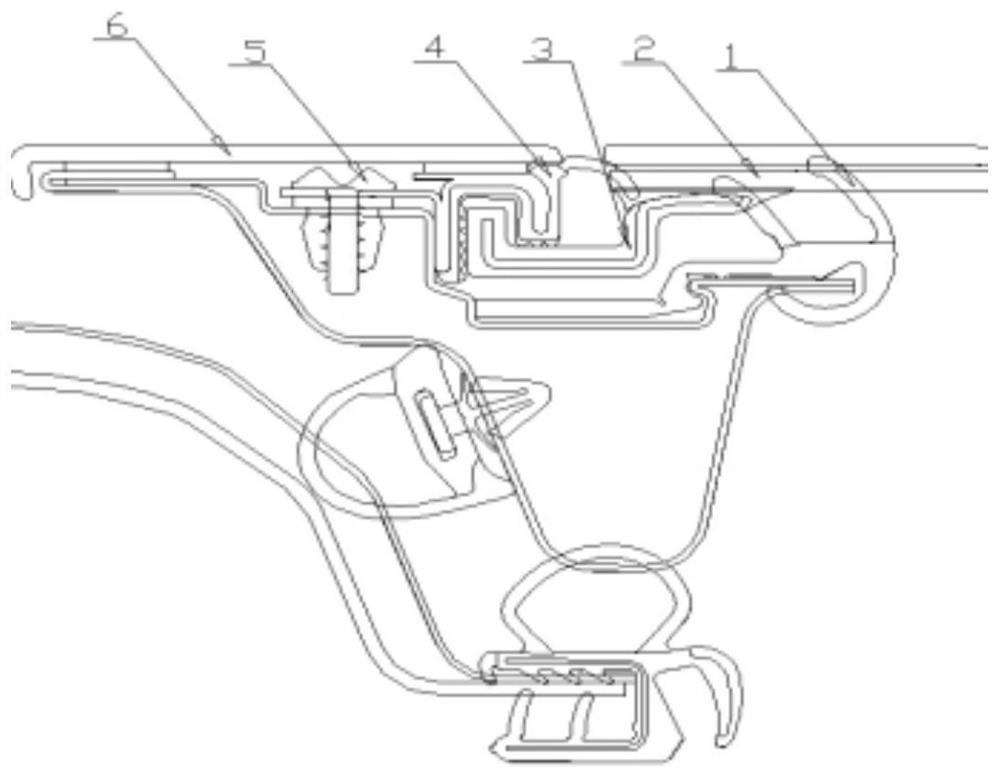

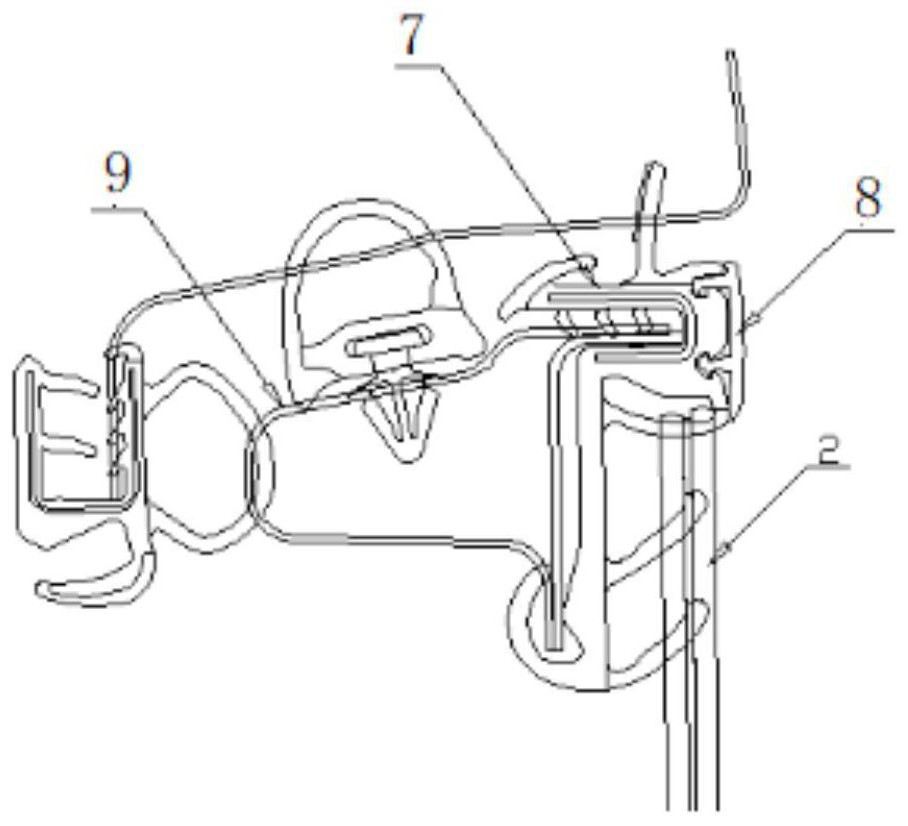

[0021] Please refer to Figure 1 to Figure 3 , a new type of stamped car door zero-surface difference B-pillar seal section and top seal strip section structure of the present invention, which is used to seal the lift glass of the car door, figure 2 On the structure of the sealing strip, there is a slider 3 parallel to the direction of the door lifting glass. The slider 3 is embedded in the sliding rail sealing strip 4. One side of the slider is connected to the glass 2 and drives the lifting glass. On the sliding rail sealing strip 4 and the sealing strip 1 of the glass run groove, the appearance surface of the glass 2 and the B-pillar trim is flush to form zero surface difference, the surface difference of the Y direction of the top section of the glass 2 is less than 3mm, the X and Y directions of the slider and the sealing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com