Umbrella two-way vertical pump device

A vertical pump, umbrella-shaped technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of no rectification measures, large hydraulic loss, etc., and achieve operation management and Ease of maintenance, improved reliability and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

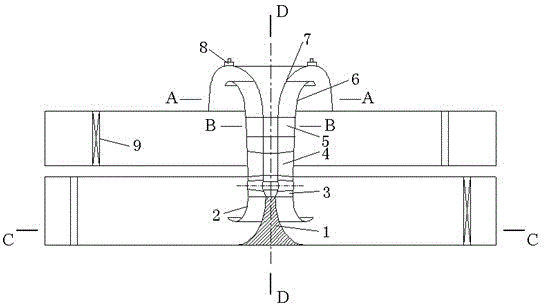

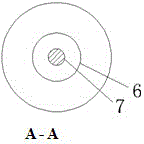

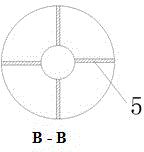

[0029]Umbrella-shaped two-way vertical pump device, consisting of two-way rectangular parallelepiped water inlet channel, rectangular parallelepiped water outlet channel, vortex elimination and anti-vortex cone 1, inlet trumpet tube 2, impeller chamber 3, guide vane body 4, racemic body 5, annular siphon water outlet Structure, rear water guide cone 7, outlet horn tube 6, hump ring shell, etc., vortex elimination and anti-vortex cone is set in the two-way cuboid water inlet flow channel under the inlet horn tube, the inlet of the impeller chamber is connected to the inlet horn tube, and the outlet of the impeller chamber is connected to the guide The leaf body, the racemic body, the rear guide water cone, and the outlet trumpet tube are sequentially arranged on the upper part of the guide vane body. The racemic body is composed of a hub, blades and a shell. The hub of the racemic body is smoothly connected with the hub of the guide vane body and the rear guide water cone respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com