Steam explosion device for plant fiber processing

A technology of steam explosion device and plant fiber, which is applied in the field of steam explosion, can solve the problem that the steam explosion device is difficult to achieve rapid blasting, and achieve the effect of improving equipment safety and operability, improving replaceability, and improving roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

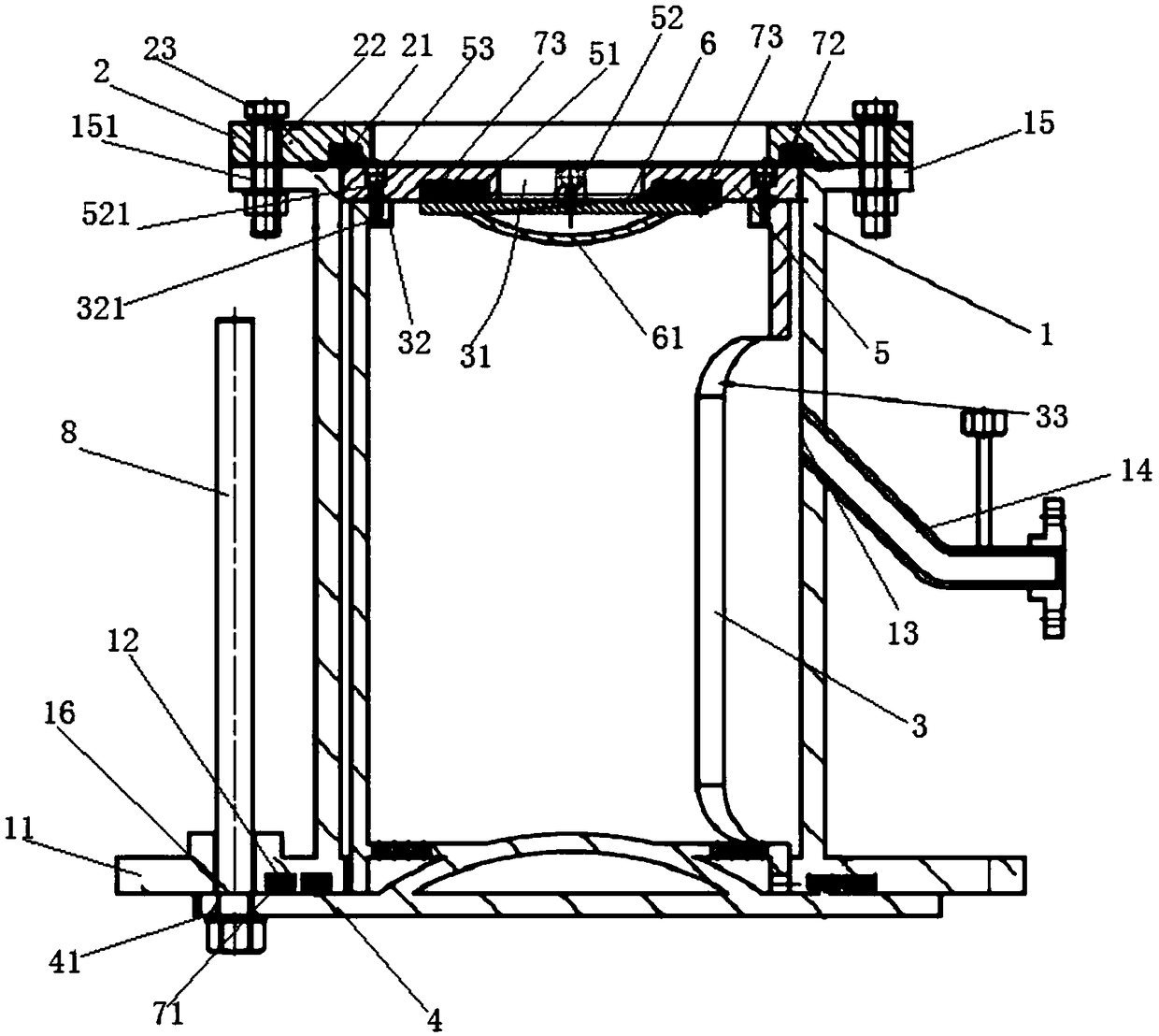

[0031] see figure 1 , a steam explosion device for plant fiber processing provided by the present invention, the steam explosion device includes: an outer warehouse 1, shaped as a tube body, placed vertically, the outer wall of the lower opening end of the outer warehouse 1 is along the outer circumferential direction of the outer warehouse An annular lower connecting portion 11 is protrudingly provided, and at least one annular first sealing groove 12 is provided along the circumferential direction of the annular lower connecting portion at both ends of the lower surface of the annular lower connecting portion 11 close to the lower opening end. An air inlet 13 is provided, and a high-temperature and high-pressure air inlet pipe 14 is inserted into the air inlet 13 to form the passage of high-temperature and high-pressure gas; an annular cover plate 2 is provided on the upper opening end of the outer warehouse 1 and connected The warehouse 1 forms a detachable connection, the ...

Embodiment 2

[0038] The outer wall of the upper opening end of the outer warehouse 1 protrudes along the outer circumference of the outer warehouse 1 with an annular upper connecting portion 15, and the two ends of the annular upper connecting portion 15 are respectively provided with an upper connecting hole 151, correspondingly, the two ends of the annular cover plate 2 are respectively An upper connection through hole 22 corresponding to the upper connection hole 151 is opened, and two fixing members 23 are inserted in the upper connection through hole 22 and the upper connection hole 151 to form a detachable connection between the annular cover plate 2 and the outer warehouse 1 . All the other are with embodiment 1.

Embodiment 3

[0040] The inner wall of the upper port of the inner chamber 3 protrudes along the horizontal direction with an annular protrusion 32, and the two ends of the upper surface of the annular protrusion 32 are respectively provided with a blind installation hole 321 along the vertical direction. Correspondingly, the two ends of the annular bottom plate 5 Mounting holes 521 matching the blind mounting holes 321 are provided respectively, and the fixing rods 53 are inserted into the mounting holes 521 and the blind mounting holes 321 to form a detachable connection between the annular bottom plate 5 and the inner compartment 3 .

[0041] Wherein, the fixing rod 53 is a bolt, and the distance is designed according to the pressure vessel design standard, and the hole distance is less than 4.5 times the diameter of the bolt. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com