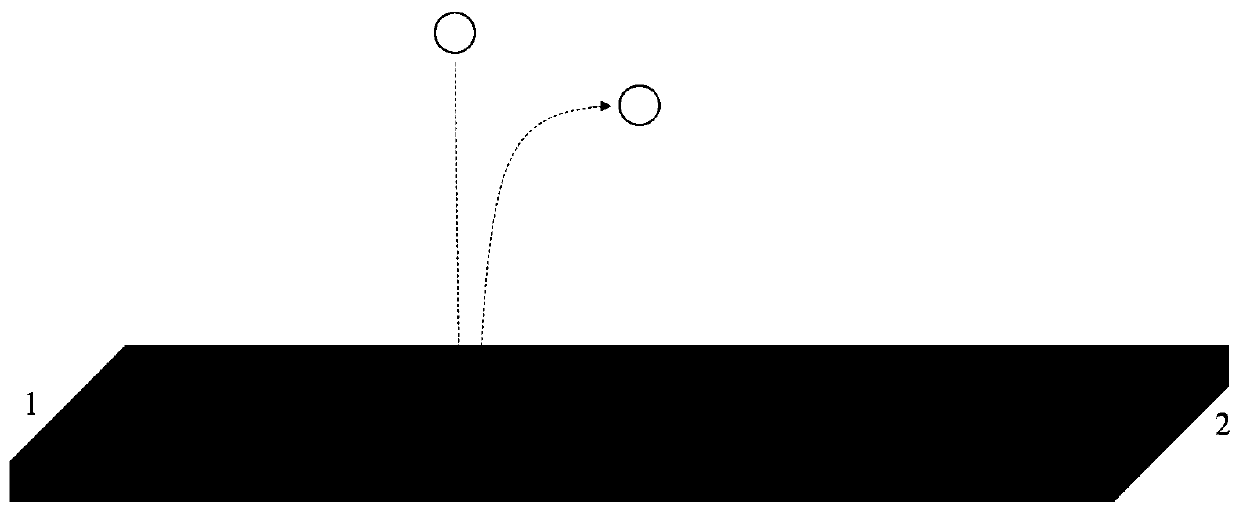

Control method of liquid drop bounce direction based on surface wetting gradient

A control method and droplet technology, which are applied in the process of producing decorative surface effects, manufacturing microstructure devices, gaseous chemical plating, etc., can solve the problems of high cost, unstable performance, and many steps, and achieve low cost. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

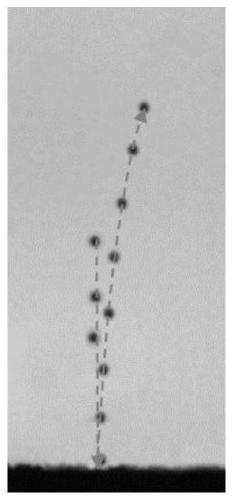

[0032] A control method for controlling the bouncing direction of a droplet based on a surface wetting gradient, comprising the following steps:

[0033] (1) with Ti 6 al 4 V titanium alloy is the base material, and the base material is processed into a sample block with a size of 50mm×10mm×1mm by wire cutting, and then the surface of the sample block is polished with 0~5# metallographic sandpaper until there is no scratch on the naked eye, and then mechanically Polish until there are no scratches under metallographic microscope observation, then use acetone, alcohol and distilled water to ultrasonically clean for 10 minutes, dry to obtain the pretreated sample block, and store it in alcohol for later use;

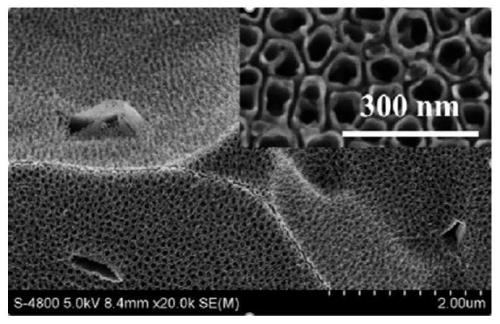

[0034] (2) Use the sandblasting method to construct the primary micron-scale concave-convex structure. The specific process parameters of the sandblasting method are pressure 0.5MPa and sandblasting time 10s; after that, the sample block processed by the sandblasting meth...

Embodiment 2

[0038] A control method for controlling the bouncing direction of a droplet based on a surface wetting gradient, comprising the following steps:

[0039] (1) with Ti 6 al4 V titanium alloy is the base material, and the base material is processed into a sample block with a size of 60mm×10mm×1mm by wire cutting, and then the surface of the sample block is polished with 0~5# metallographic sandpaper until no scratches are observed with the naked eye, and then mechanically polished Until no scratches are observed under the metallographic microscope, then use acetone, alcohol and distilled water to ultrasonically clean for 10 minutes, and dry to obtain the pretreated sample block, which is stored in alcohol for later use;

[0040] (2) Use the sandblasting method to construct the primary micron-scale concave-convex structure. The specific process parameters of the sandblasting method are pressure 0.5MPa and sandblasting time 10s; after that, the sample block processed by the sandbla...

Embodiment 3

[0044] A control method for controlling the bouncing direction of a droplet based on a surface wetting gradient, comprising the following steps:

[0045] (1) Using aluminum alloy as the base metal, use wire cutting to process the base material into a sample block with a size of 100mm×20mm×1mm, and then use 0~5# metallographic sandpaper to polish the surface of the sample block until no scratches are observed with the naked eye, and then Perform mechanical polishing until no scratches are observed under the metallographic microscope, then use acetone, alcohol and distilled water to ultrasonically clean for 10 minutes, and dry to obtain the pretreated sample block, which is stored in alcohol for later use;

[0046] (2) Use the sandblasting method to construct the primary micron-scale concave-convex structure. The specific process parameters of the sandblasting method are pressure 0.5MPa and sandblasting time 10s; after that, the sample block processed by the sandblasting method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com