Method and device for catalytic cracking of heavy oil

A heavy oil catalysis and catalyst technology, which is applied in the field of catalytic cracking, can solve the problems of high regenerator coking temperature and excess heat removal of regenerator, and achieve the effects of reducing dry gas and coke yield, reducing residence time and promoting contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] This example illustrates but is not limited to the situation that the method provided by the present invention is used to carry out the catalytic reaction of heavy oil to produce clean products.

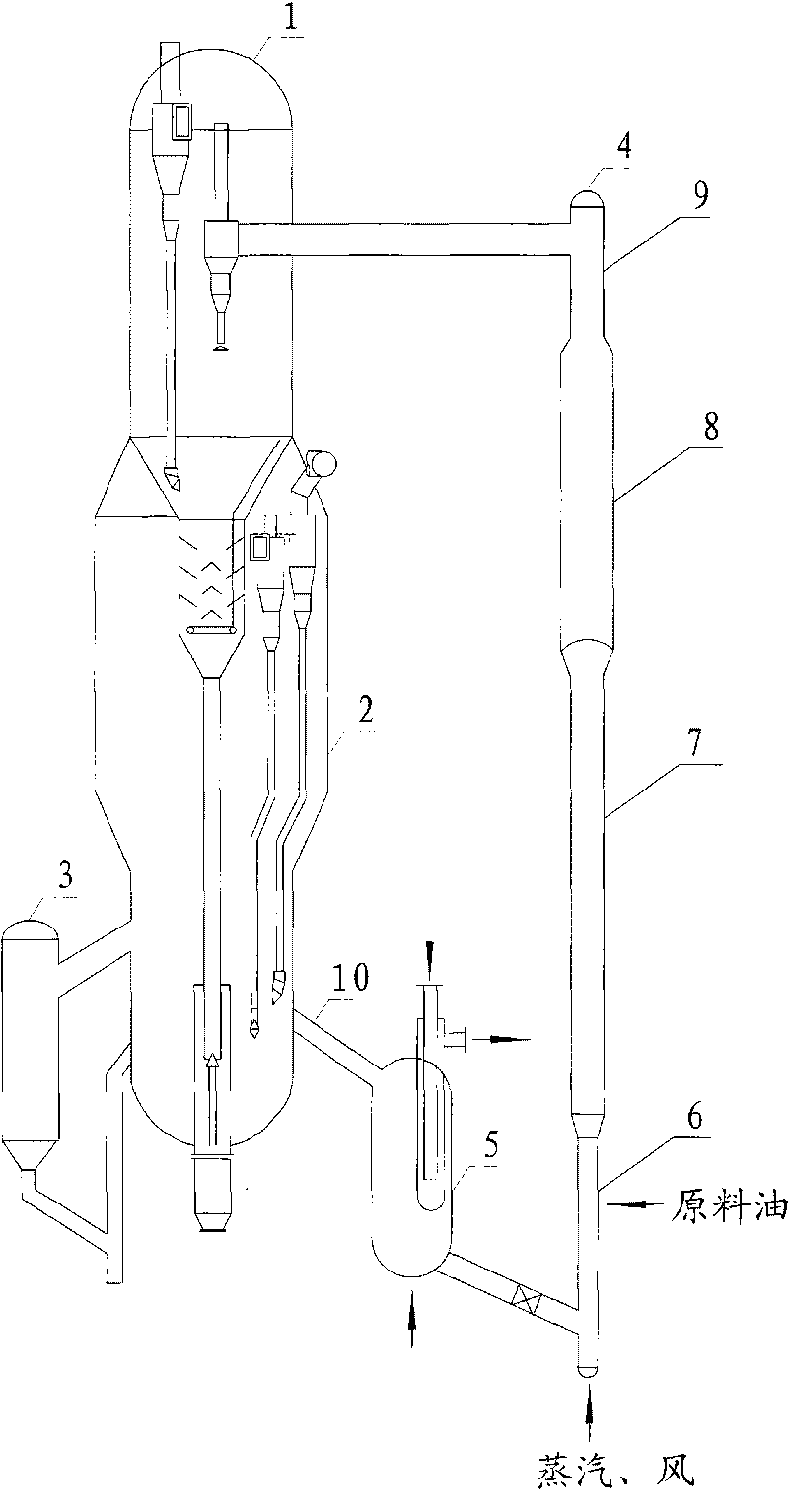

[0041] as attached figure 2 As shown, the raw oil pipeline is injected into the first reaction zone 7 of the different-diameter riser reactor 4, and contacts and reacts with the cold catalyst lifted by water vapor in the lower part of the first reaction zone 7. The cold catalyst is regenerated from The device 2 cools down through the external heat extractor 5 of the regeneration inclined tube and enters the bottom of the riser reactor 4. The weight ratio of catalyst and raw oil in the first reaction zone 7 is 8:1, the residence time of the raw material oil in the first reaction zone 7 is 1 second, the temperature in the first reaction zone 7 is 526 ° C, and the oil mixture continues to go up into the first reaction zone. The second reaction zone 8, the bed density of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com