Intelligent dust suppression system and method

An intelligent, system-controlled technology, applied in loading/unloading, climate sustainability, railway transportation, etc., can solve problems such as high wind power and high cost, and achieve the effect of reducing size, saving energy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

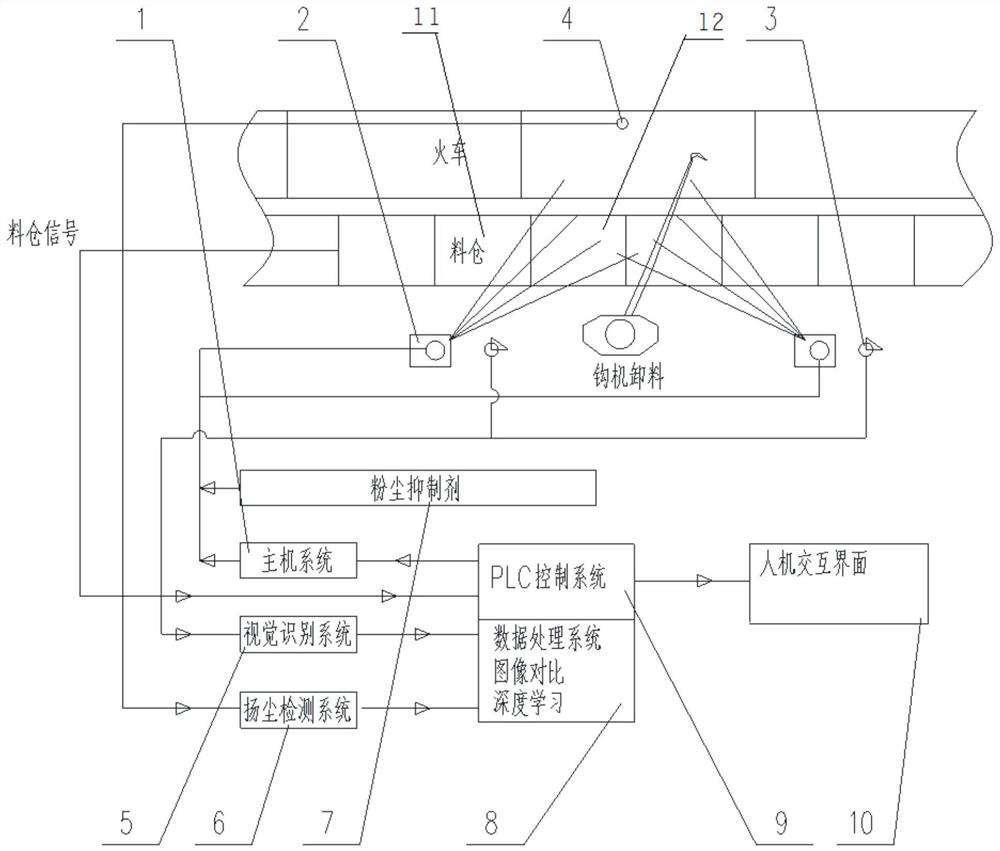

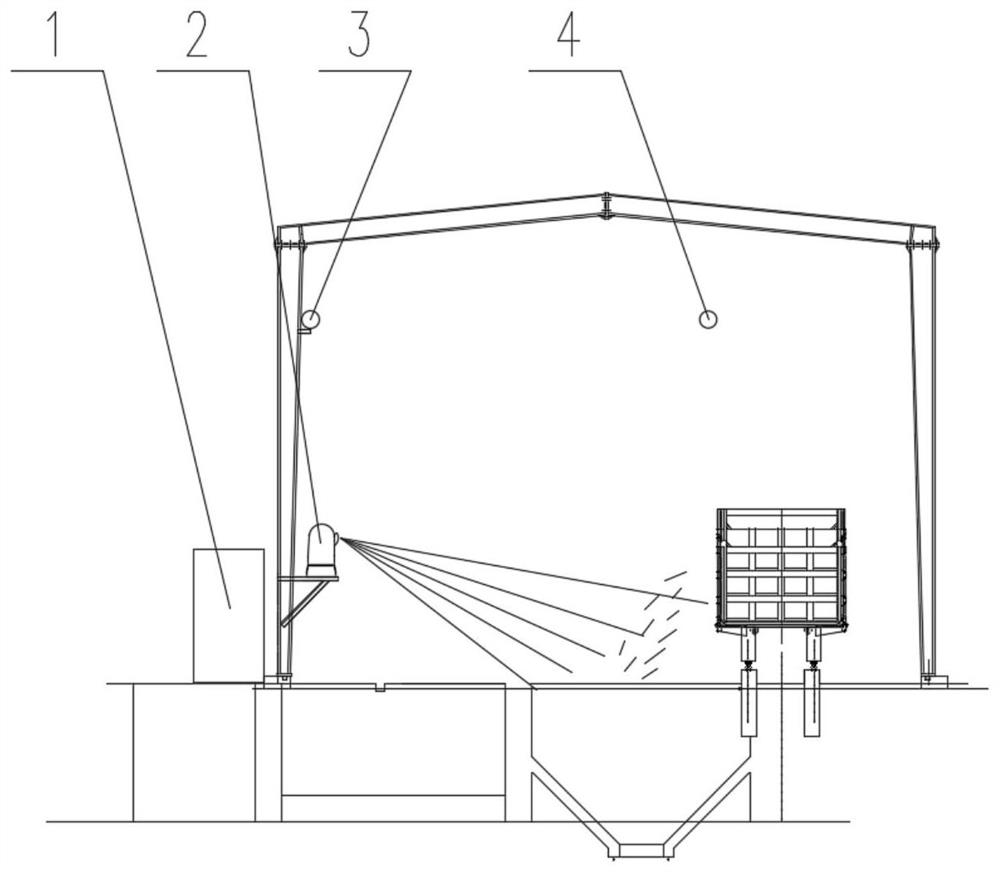

[0052] like Figure 1 - Figure 5 , The present invention provides an intelligent dust suppression system, comprising:

[0053] Dust unloading system for unloading a train compartment for dust suppression hook machine work unloading process;

[0054] Discharge dust suppression system for dust suppression during the work train Open discharge of the material;

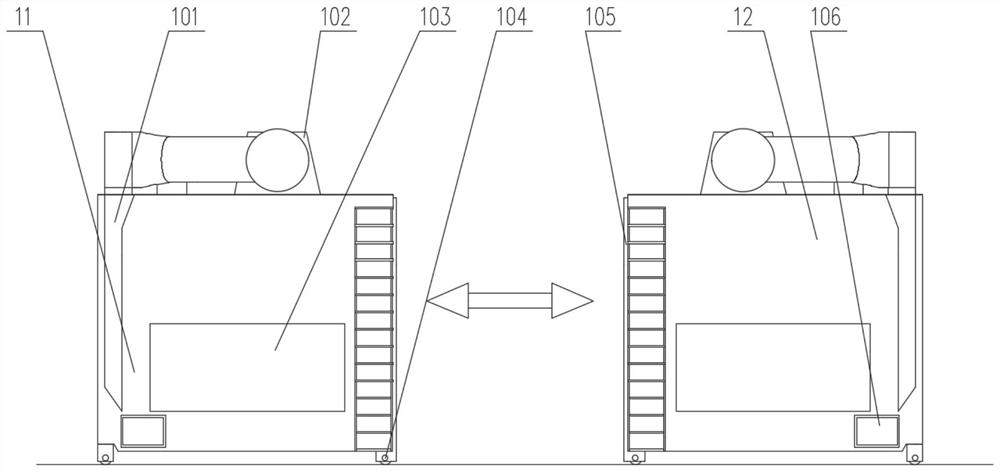

[0055] Wherein said discharge dust suppression system includes a left mirror images of moving cover 11, the right movable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com