Cast-in-place prestressed concrete sandwiched composite beamless floor slab structure

A beamless floor slab and concrete technology, which is applied in the direction of floor slabs, building components, building structures, etc., can solve problems such as steel bar erosion, achieve the effects of reducing project cost, easy handling, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

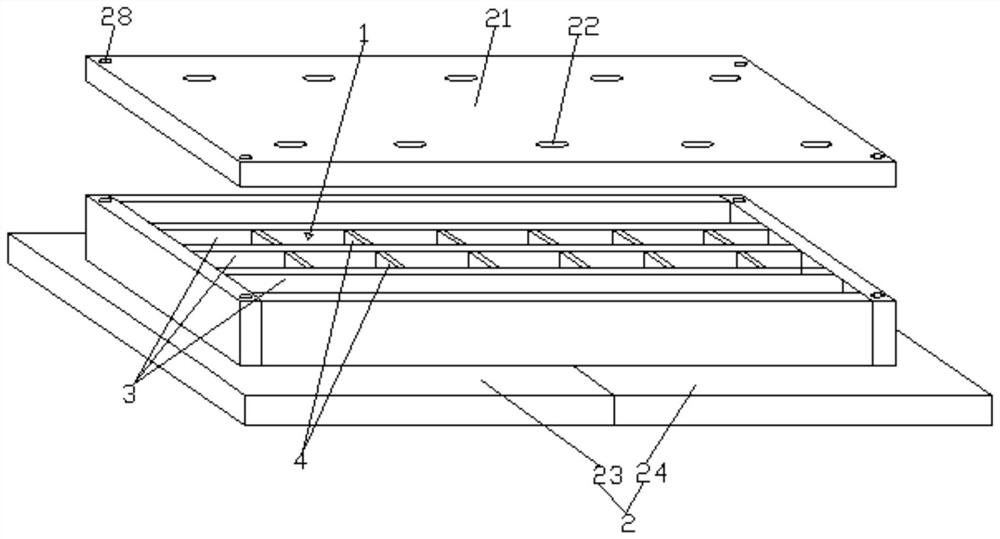

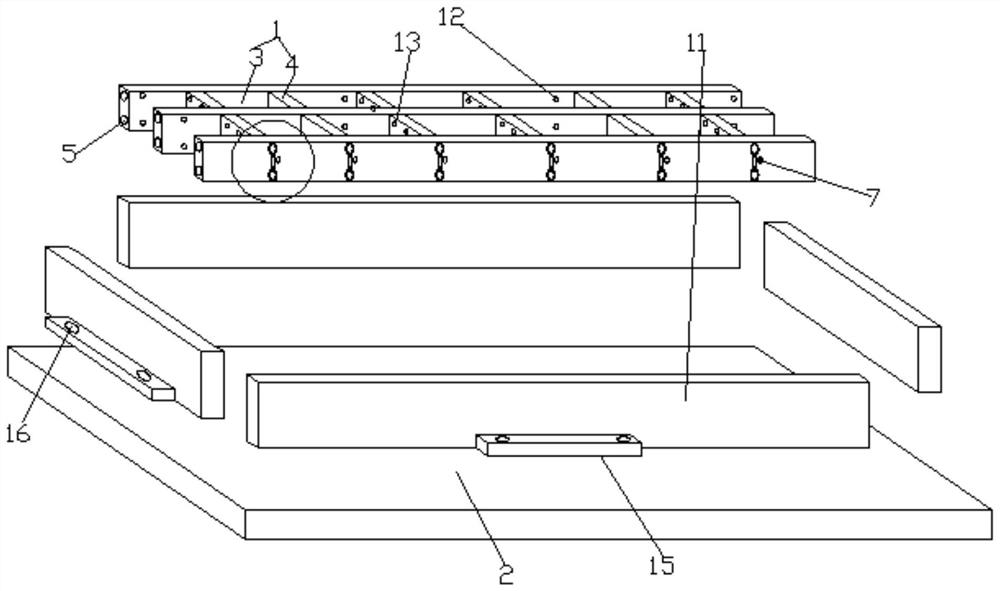

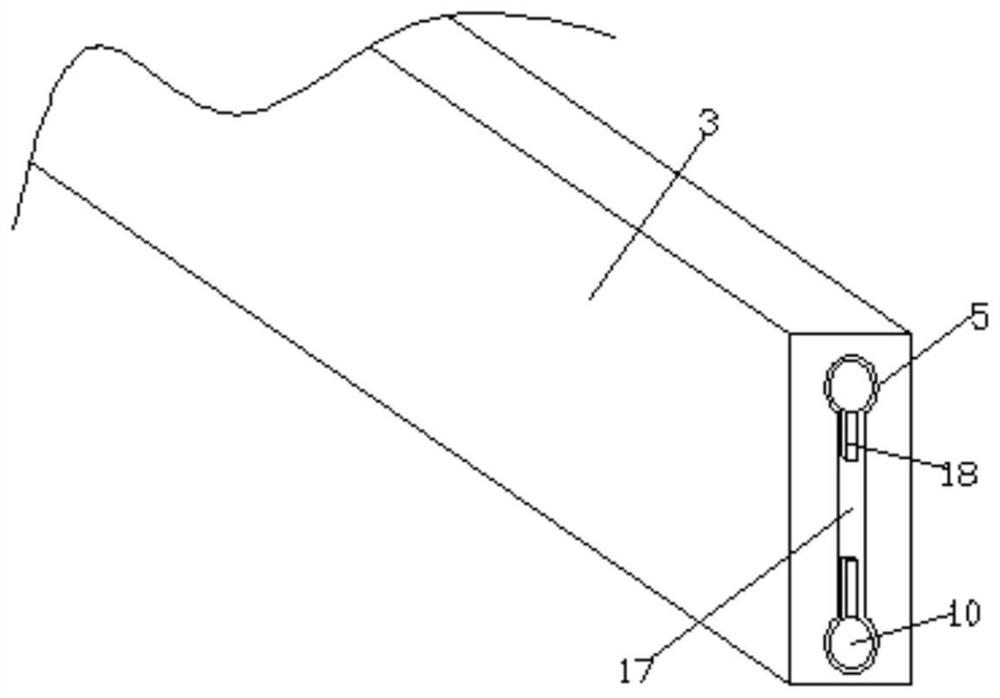

[0033] see Figure 1-6 , according to an embodiment of the present invention, a cast-in-situ prestressed concrete sandwich composite beamless floor structure includes a beamless floor body 1 and a bottom formwork 2, the bottom formwork 2 is arranged at the bottom of the beamless floor body 1, and the The beamless floor body 1 includes several transverse partition panels 3, and the adjacent transverse partition panels 3 are fixedly connected by several reinforcing panels 4, and the interior of the transverse partition panels 3 and the reinforcing panels 4 Both are cavity structures, the transverse partition plate 3 is provided with a transverse reinforcement hole 5, and the common connection between the reinforcement plate 4 and the transverse partition plate 3 is provided with a vertical reinforcement hole 6 and a pipeline hole 7, so A line pipe 8 is arranged in the pipeline hole 7, a vertical steel bar 9 is arranged in the vertical steel bar hole 6, a horizontal steel bar 10 ...

Embodiment 2

[0035] see Figure 1-4, the number is four on the outer wall of the surrounding board 11 is fixed with a mounting plate 15, the mounting plate 15 is provided with a threaded hole 16, each of the lateral partitions 3 provided with the lateral The number of reinforcing bar holes 5 is two, and connecting grooves 17 are arranged between the transverse reinforcing bar holes 5 on each of the transverse dividing plates 3, and the connecting grooves 17 communicate with the outside, and the transverse reinforcing bars 10 Inserted into the horizontal steel bar hole 5, and the corresponding side of the horizontal steel bar 10 is evenly distributed with in-line reinforcing ribs 18, and the vertical steel bar holes provided on each of the reinforcing plates 4 The number of 6 is two, and a secondary connection groove 19 is provided between the vertical reinforcement holes 6 on each of the reinforcing plates 4, and the secondary connection groove 19 communicates with the outside, and the ver...

Embodiment 3

[0038] see Figure 1-5 , the pillars 14 pass through the bottom formwork 2 and the beamless floor body 1 together, the bottom formwork 2 is divided into a left formwork 23 and a right formwork 24, and the junction of the left formwork 23 and the right formwork 24 Both are provided with a half-through slot, and the two half-through slots are merged into a full-through slot. The pillar 14 passes through the full-through slot. The sound insulation mechanism includes a sound insulation board 25, the bottom of the sound insulation board 25, the The beamless floor body 1 is fixed with a corresponding corresponding plate 26, and the corresponding plate 26 and the pillar 14 are provided with several corresponding openings, and steel bars are provided in the openings. The interior of the sound insulation board 25 is filled with sound insulation cotton, and several leak grooves are evenly distributed on the sound insulation board 25, and the secondary penetration opening 27 for the pill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com