Track-type intelligent logistics robot charging system and charging method

A technology of intelligent logistics and charging system, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of waste of space, high cost of use, low efficiency of logistics robots, etc., to reduce costs, save space, and facilitate the later stage. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following combination of attachments and specific embodiments to further explains the present invention in detail, not to limit the implementation of the invention.

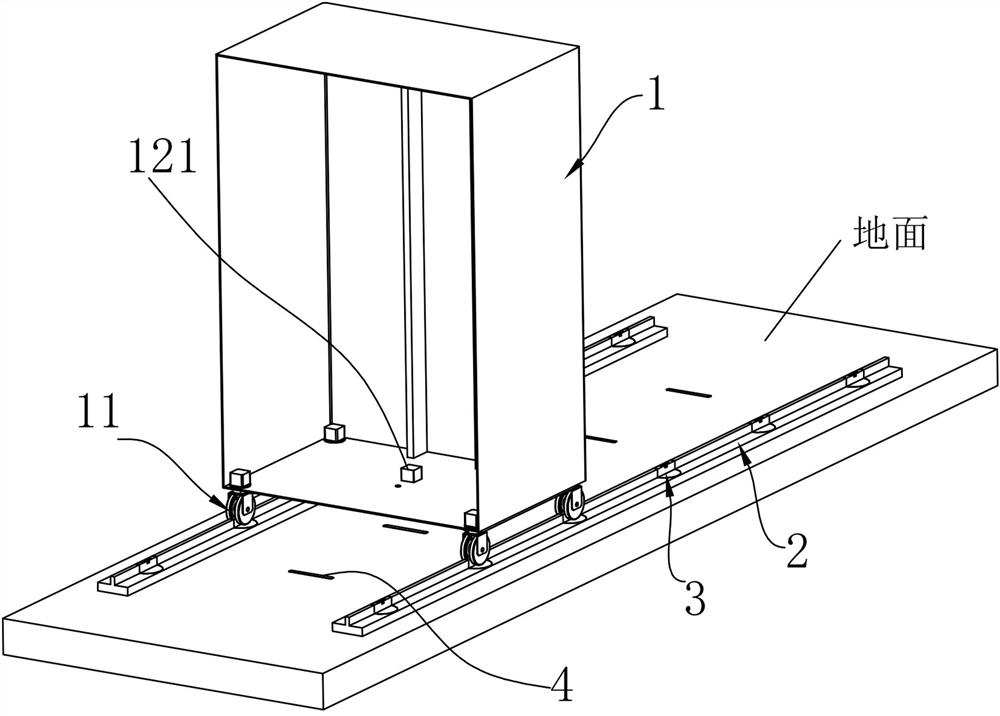

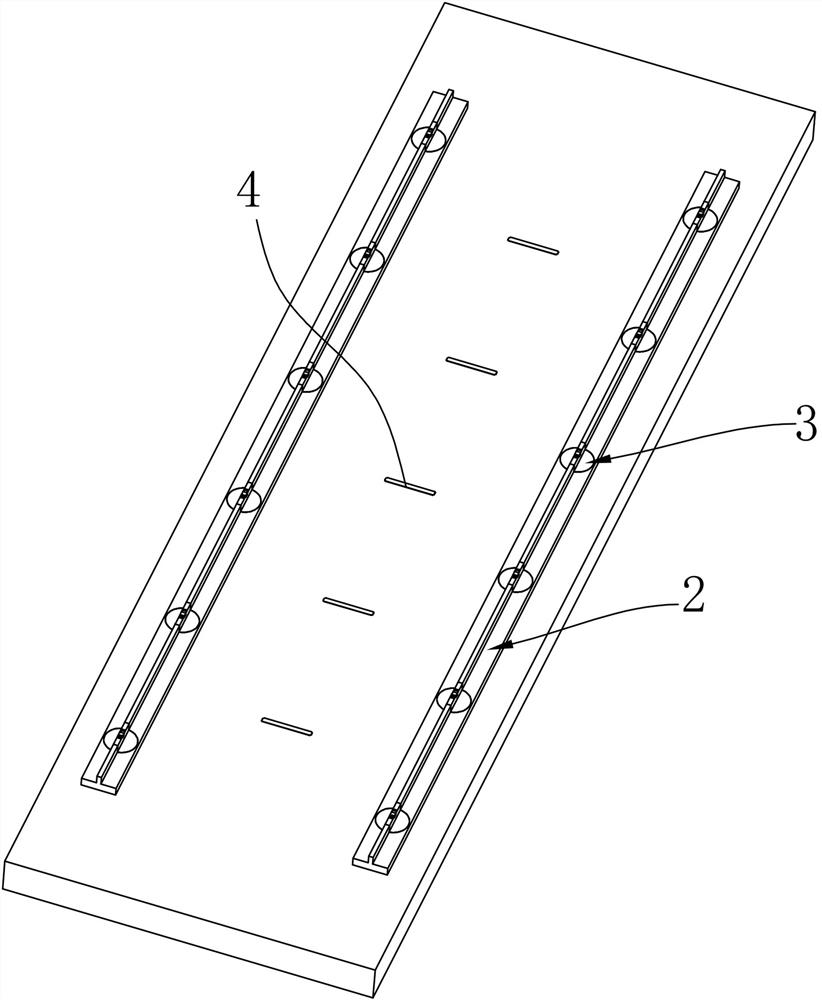

[0035] like Figure 1 to Figure 13 Show, a rail -type intelligent logistics robot charging system described in this example, including the charging track 2 installed on the ground on the ground by transshipment robot 1 and two;

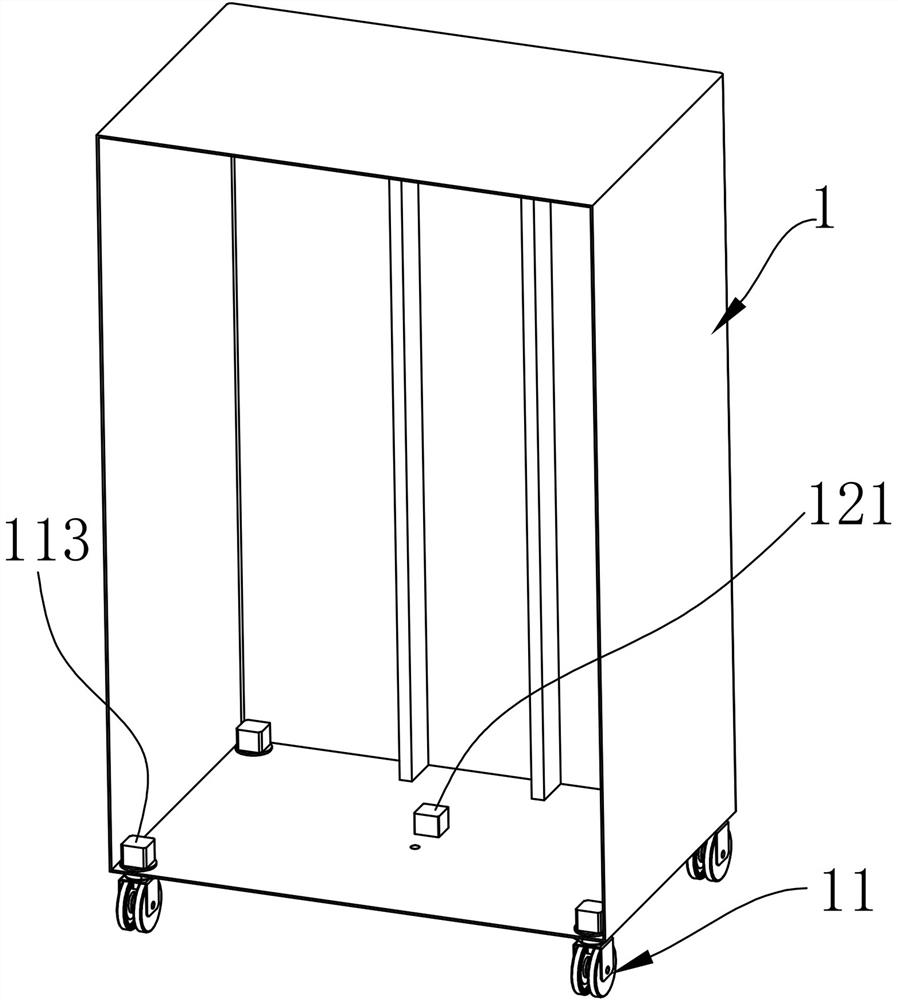

[0036] The four corner positions at the bottom of the transshipment robot 1 are installed to drive the transfer robot 1 with a displacement drive agency 11 along the charging orbit 2. Also installed for the steering drive mechanism of the four displacement drive mechanisms for synchronous drivers. 12;

[0037] Each charging orbit 2 has a charging connection mechanism 3, which is connected to the charging orbit 2, two spacing between the displacement drive mechanism 11 with the same charging orbit 2 slide Equal between the distance between the two charging mechanisms of the same cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com