Preparation method of waterproof mortar

A technology of waterproof mortar and fine powder, which is applied in the field of waterproof mortar and can solve problems such as the inability to efficiently prepare waterproof mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

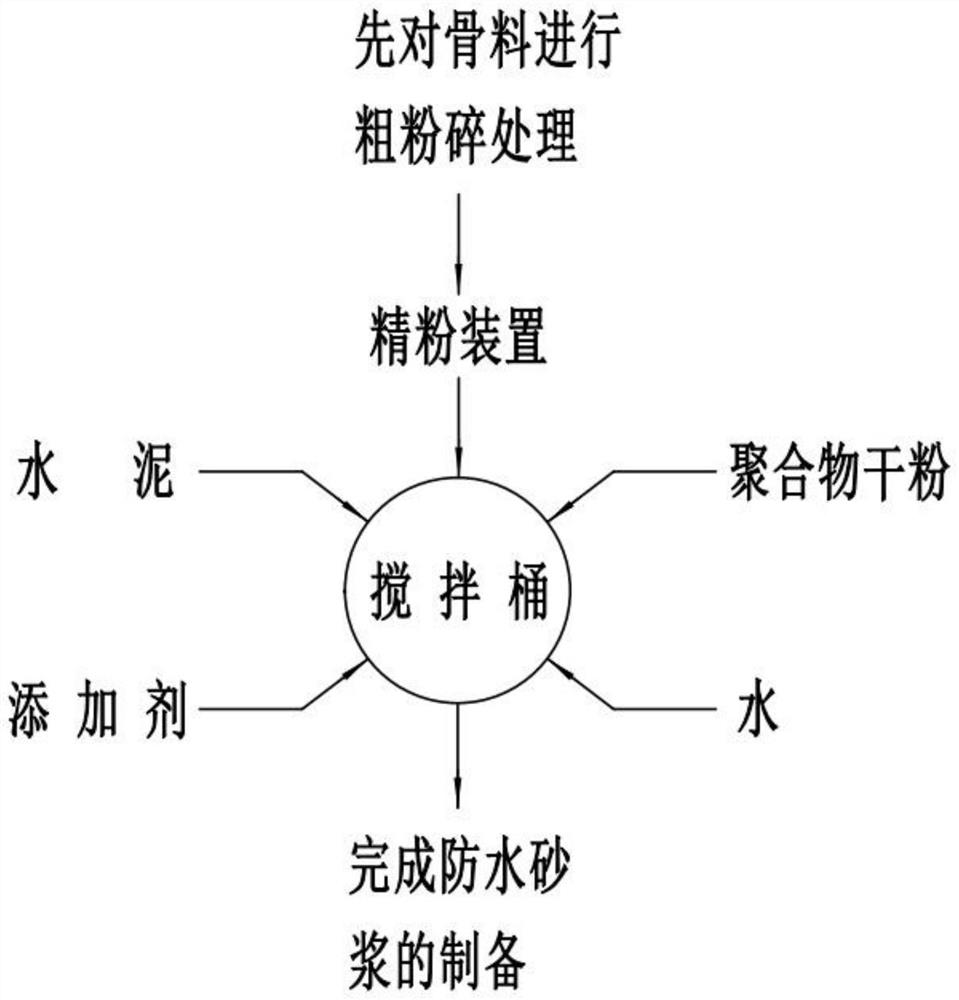

[0044] Attached below figure 1 In detail, a method for preparing waterproof mortar includes the following steps: S1, coarsely pulverizing the aggregate;

[0045] S2. Add the coarsely crushed material to the fine powder device to complete the fine powder treatment of the aggregate;

[0046] S3. Add qualified materials, cement, polymer dry powder, additives and water into the mixing tank;

[0047] S4. Stirring is carried out in the mixing tank, so that various materials are uniformly mixed together, and the preparation of waterproof mortar is completed.

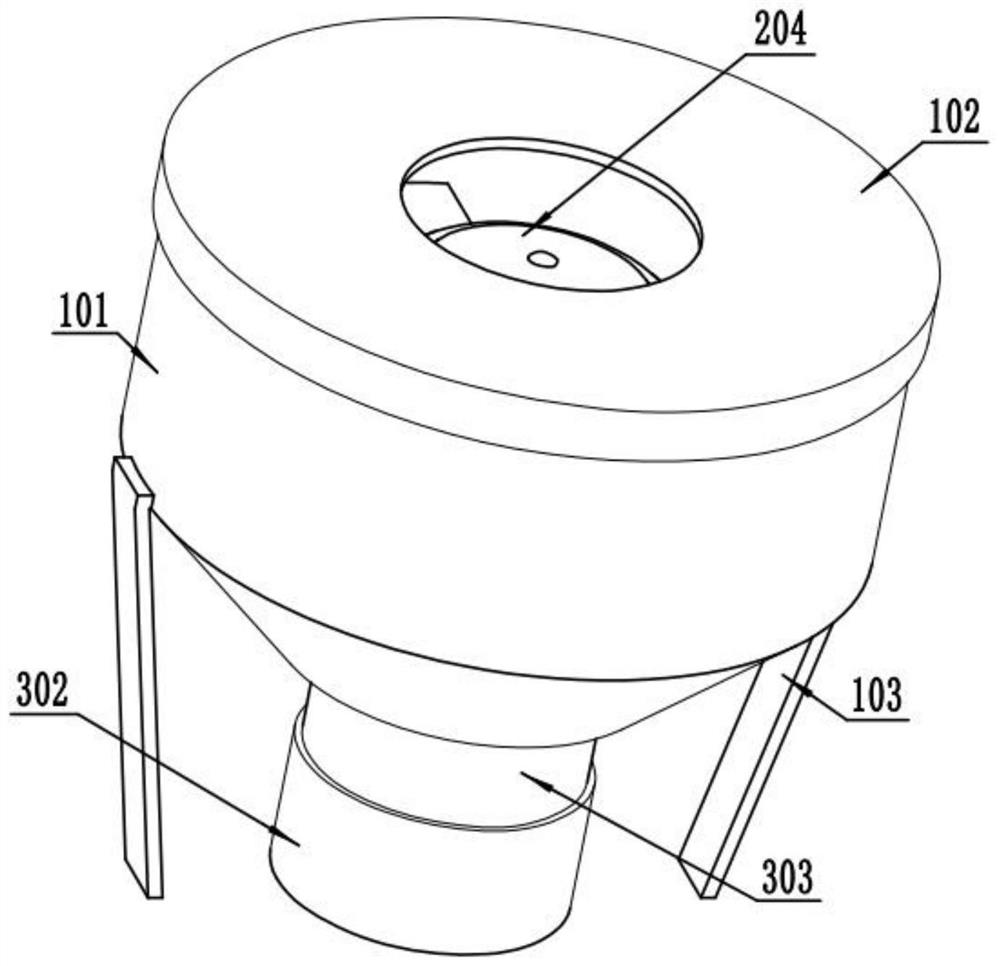

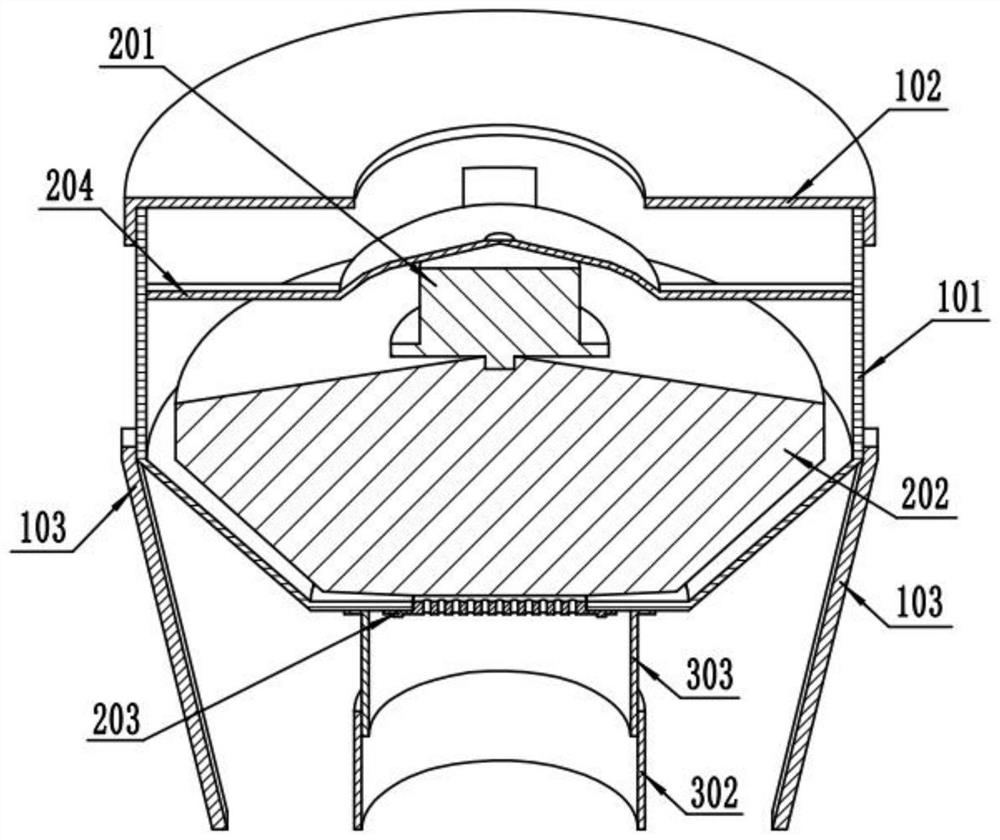

[0048] Attached below figure 2 with 3 In detail, the fine powder device includes a fine powder chamber 101, a shield cover 102, a support leg 103, a grinding member and a filter plate 203, a shield cover 102 is slidably connected to the fine powder chamber 101, and the support leg 103 is provided with Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com