Prefabricated limiting piece, spar cap, fan blade and manufacturing method, and prefabricated panel fixing method

A technology for fan blades and a manufacturing method, applied in the field of fan blades, can solve the problems of slow interlayer perfusion, poor interlayer resin infiltration, and reduced sheet bonding strength, so as to reduce mold investment costs, reduce personnel costs, and improve stability. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] Such as Figure 8A , 8B As shown in , 8C, this embodiment provides a prefabricated limiting member 8, which at least includes a pair of upper and lower locking grooves arranged continuously along the groove width direction. The groove width direction Y of the prefabricated limiting member is shown in the figure. The width of the upper slot and the lower slot are both set to a multiple of the width of at least one prefabricated panel 7, and the heights of the upper slot and the lower slot are both set to the height of the prefabricated panel 7. In this embodiment, an embodiment in the form of a slot of the prefabricated limiting member 8 is provided, and the slot structure is used to prevent relative slippage and edge protrusion caused by misalignment of the prefabricated board 7 .

[0153] In this embodiment, the prefabricated limiting member 8 includes at least one first folded edge 810, at least one second folded edge 820, at least one first concave surface 840, at l...

Embodiment 2

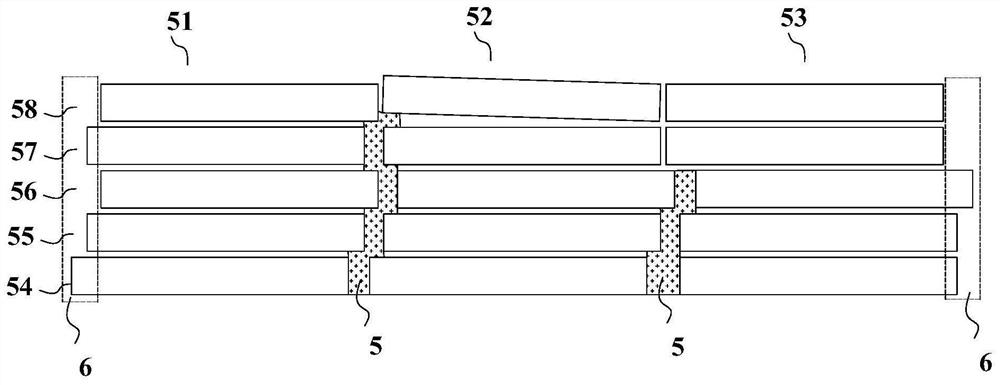

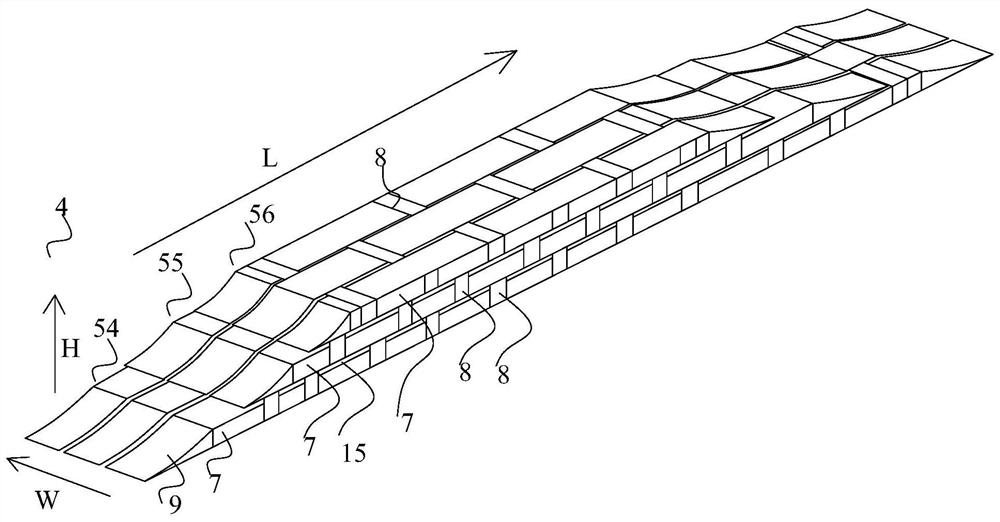

[0158] Such as image 3 , 4 , 5A, 5B, 6, 7A, 7B, the present embodiment provides a spar cap 4, the spar cap 4 includes at least two stacks arranged along the longitudinal direction of the spar cap 4, wherein at least two The stacks are arranged adjacent to each other in the width direction of the spar caps 4 and each of the at least two stacks comprises pultruded fiber-reinforced polymers stacked on top of each other in the height direction of the spar caps 4 Plates, stacking a plurality of adjacent prefabricated plates 7 located on the same layer in the width direction is to fix the prefabricated plates 7 to each other in a certain way in the width or height direction by the prefabricated limiting parts 8 and end fixing parts 10 interspersed therebetween; , the prefabricated limiting parts 8 on two adjacent prefabricated panels 7 do not overlap in the thickness direction; at the same time, a resin flow channel 15 will be formed between the upper and lower adjacent prefabrica...

Embodiment 3

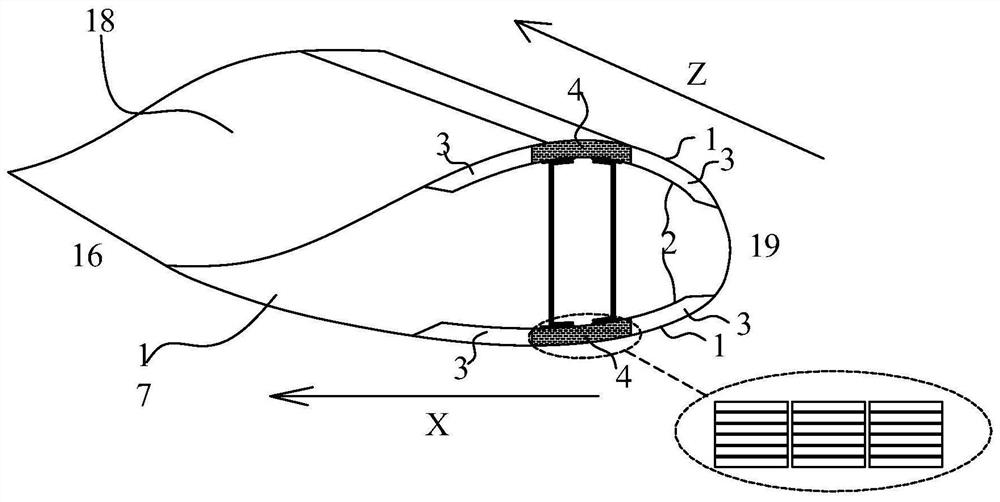

[0170] Such as figure 1 , 2 As shown, the present embodiment provides a fan blade, especially a wind turbine blade, comprising an outer skin 1, an outer skin 2, a core material, a resin, and a spar, wherein the spar has any of the above-mentioned wings The spar cap 4 is a spar cap 4 structure in which a plurality of prefabricated plates 7 are stacked for the wind turbine blade, and at least one pair of adjacent prefabricated plates 7 in the plurality of prefabricated plates 7 is bounded by a prefabricated limiting member 8 and / or a fixing member fixed;

[0171] In this embodiment, after the prefabricated plates 7 are stacked and assembled, they are put into the shell mold for integral molding, which reduces the investment in the fan blade spar cap 4 mold, reduces the mold investment cost, and further reduces the personnel cost input; the prefabricated plates are stacked and The formed spar cap 4 structure and the material content of the reinforcement are stable, which can i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com