Corrugated board printing grooving machine

A corrugated cardboard and slotting machine technology, applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of low production efficiency and inability to reset the push plate, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

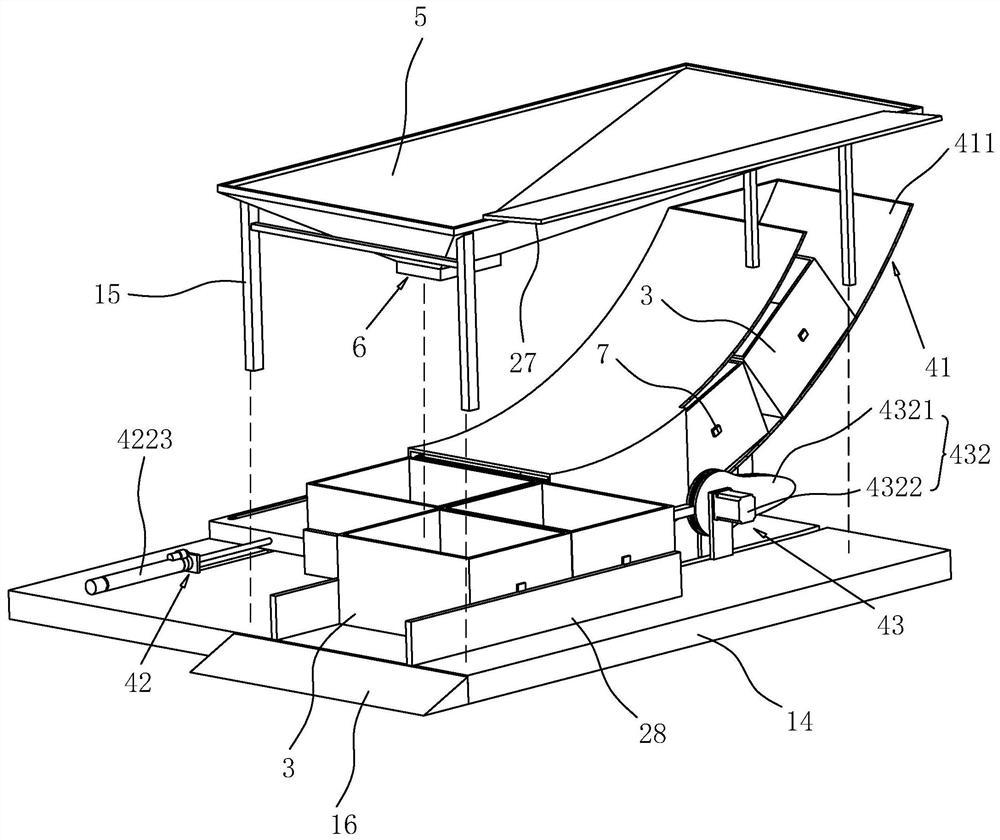

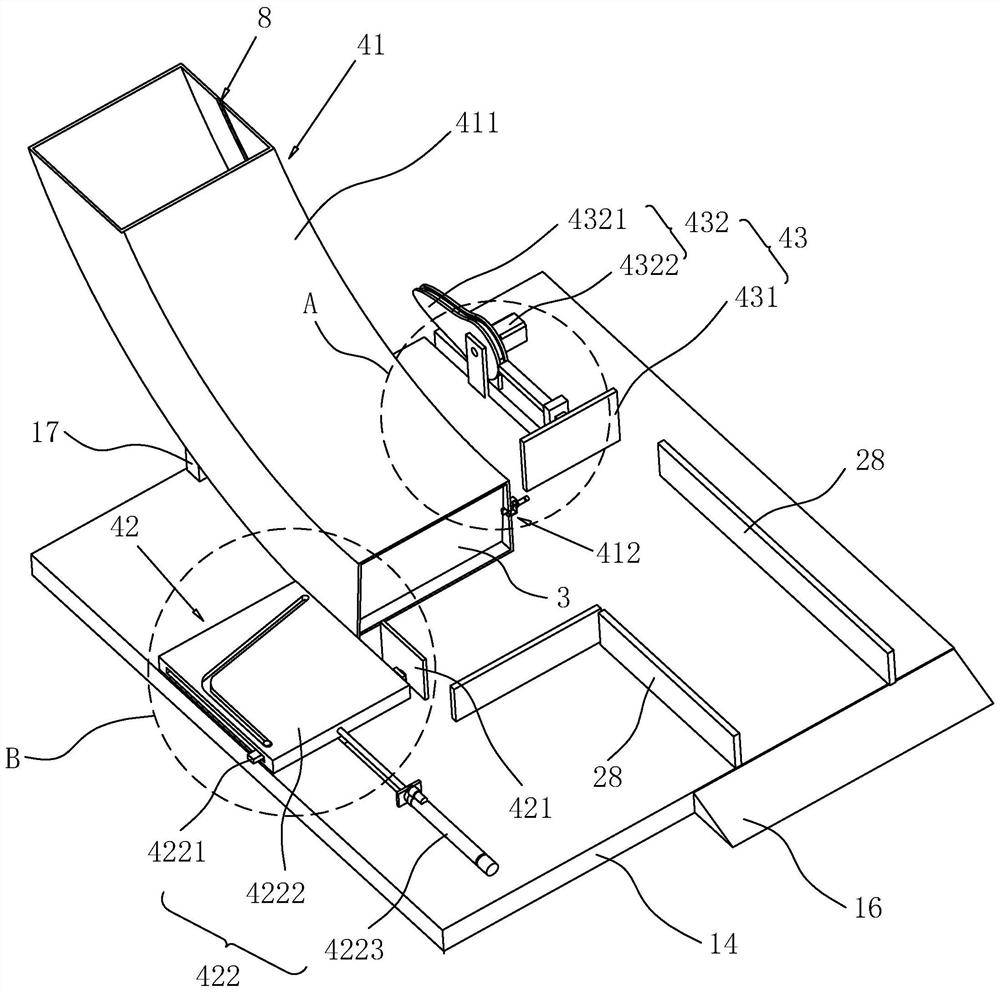

[0034] The following is attached Figure 1-5 The application is described in further detail.

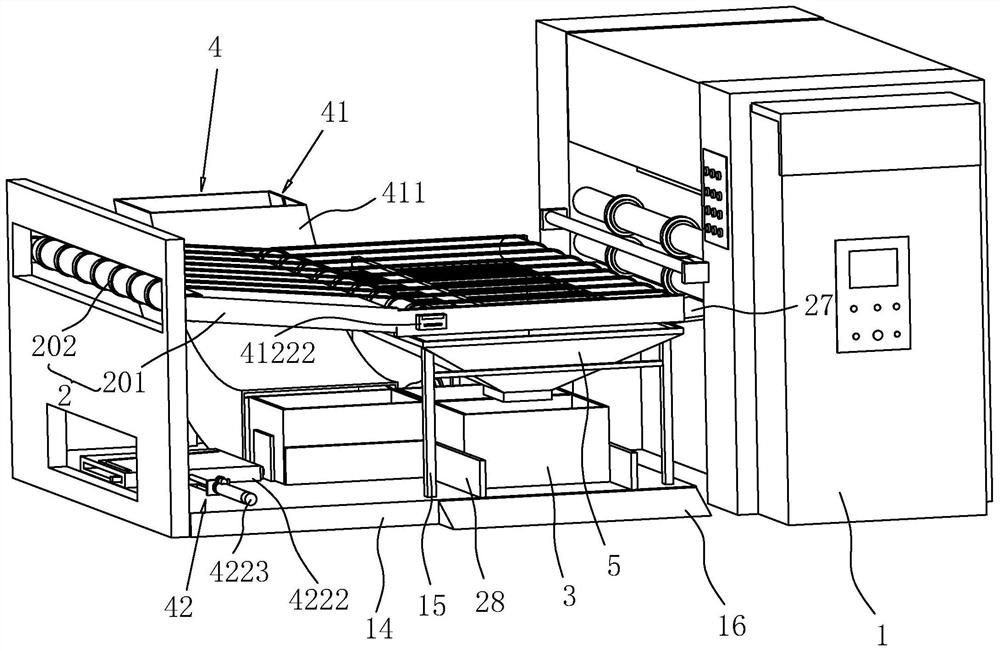

[0035] The embodiment of the present application discloses a corrugated cardboard printing and slotting machine. refer to figure 1 The slotting machine for corrugated cardboard printing includes a slotting machine body 1 and a storage rack 2 connected with the slotting machine body 1. The storage rack 2 includes a support frame 201 and multiple racks arranged at intervals on the support frame 201 for conveying corrugated cardboard. As for the set of conveyor belts 202, since both the slotting machine body 1 and the storage rack 2 belong to the prior art, no more details will be given in this embodiment.

[0036] refer to figure 1 and figure 2 , the bottom end of the support frame 201 is fixedly connected with a base plate 14, the base plate 14 is fixedly connected with a support 15, and the support 15 is fixedly connected with a receiving hopper 5. Falling paper scraps, the hop...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap