Angle-adjustable printing screen and printing device

A screen and angle technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of large adjustment error and reduce the printing quality of cells, and achieve the effect of improving the accuracy of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

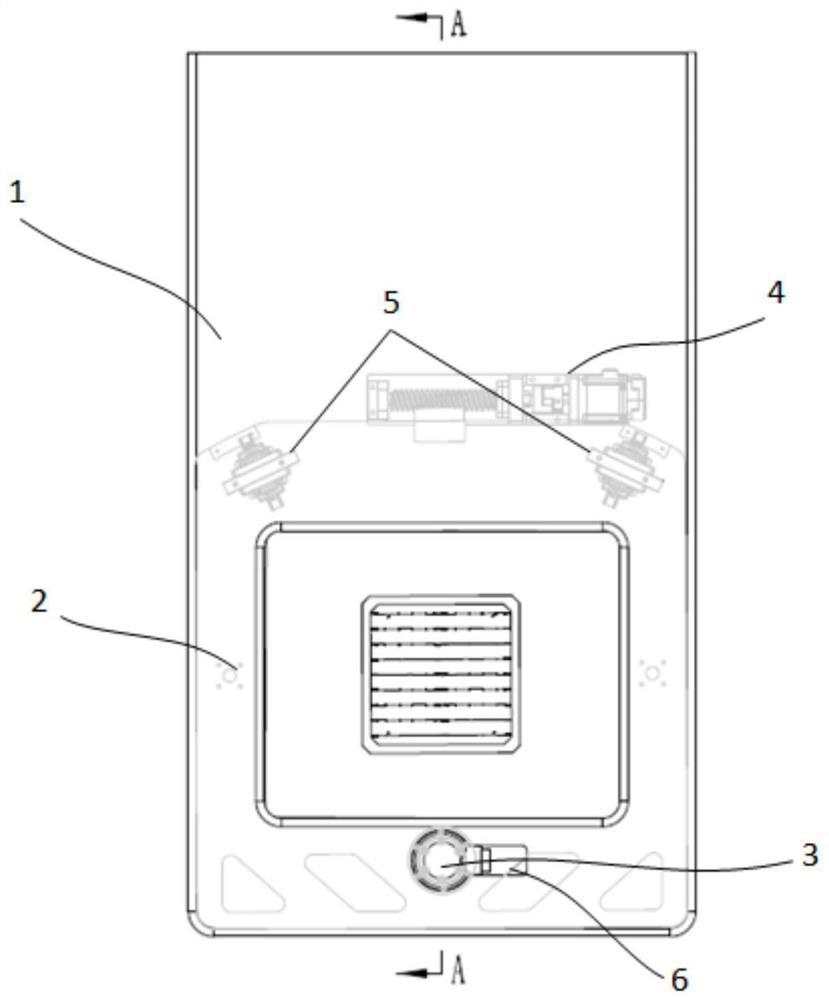

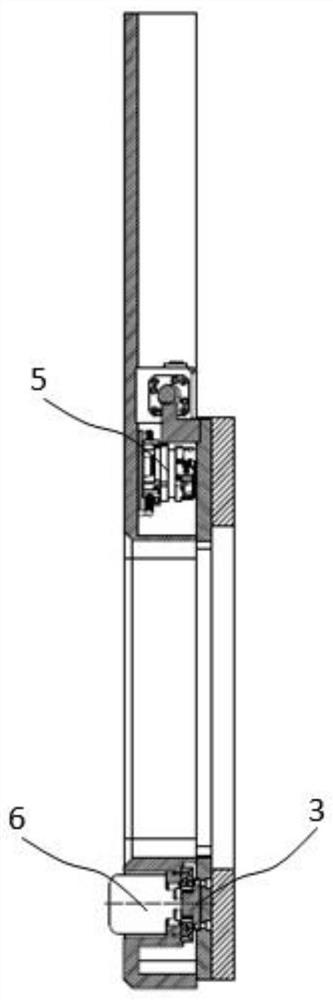

[0056] Such as figure 1As shown, the angle-adjustable printing screen provided by this embodiment includes a substrate 1, a screen assembly 2, a main shaft 3, a driving mechanism 4 and a supporting mechanism 5, wherein: the first end of the screen assembly 2 is rotatably connected to the main shaft 3 on substrate 1. The driving mechanism 4 is arranged on the substrate 1, and the driving mechanism 4 is connected to the second end of the screen assembly 2 opposite to the first end, and the driving mechanism 4 is used to drive the screen assembly 2 to rotate. The supporting mechanism 5 is arranged on the substrate 1 , and the second end of the screen assembly 2 is slidably supported on the supporting mechanism 5 .

[0057] It can be seen that the main shaft 3 as a rotating component is connected to the first end of the screen assembly 2 , and the driving mechanism 4 drives the screen assembly 2 to rotate eccentrically around the main shaft 3 , thereby realizing the angle adjustm...

no. 2 example

[0064] The structure and working principle of the angle-adjustable printing screen provided by the second embodiment of the present invention are basically the same as those of the angle-adjustable printing screen in the above-mentioned first embodiment. For the rest of the same technical points, please refer to the relevant description of the above-mentioned first embodiment.

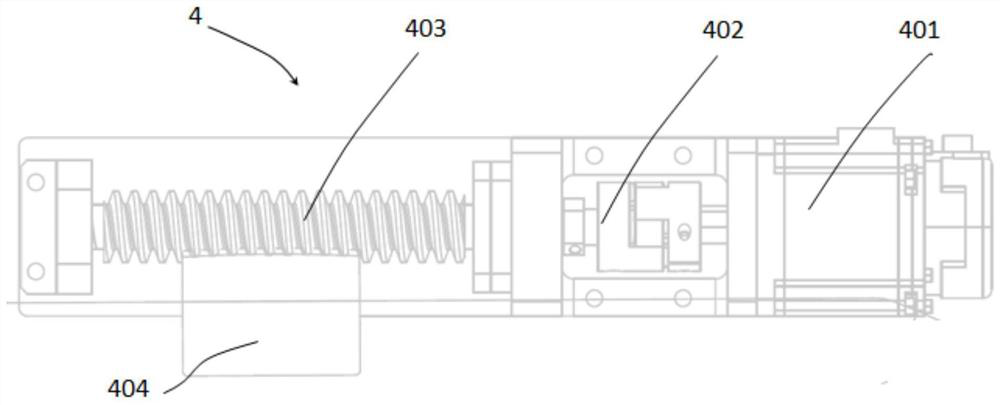

[0065] Figure 7 for Figure 6 Enlarged view of the driving mechanism 4 in, such as Figure 7 As shown, the driving mechanism 4 in this embodiment includes a second servo motor 405 , a second coupling 406 , a screw 407 , a screw nut 408 , a first crossed roller bearing 409 and a sliding rail mechanism 410 .

[0066] Wherein: the second servo motor 405 is connected on the base plate 1 , the screw rod 407 is connected to the driving end of the second servo motor 405 through the second coupling 406 , and the screw nut 408 is screwed on the screw rod 407 . The outer ring body of the first crossed roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com