Antiskid angle gauge

A technology of angle meter and guide slide rail, which is applied in the direction of instruments, measuring inclination, transmission devices, etc., can solve the problems of poor angle accuracy, insufficient support of test platform, and reduce the accuracy of detection, etc., to achieve high accuracy of angle adjustment , stable angle and high angle accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

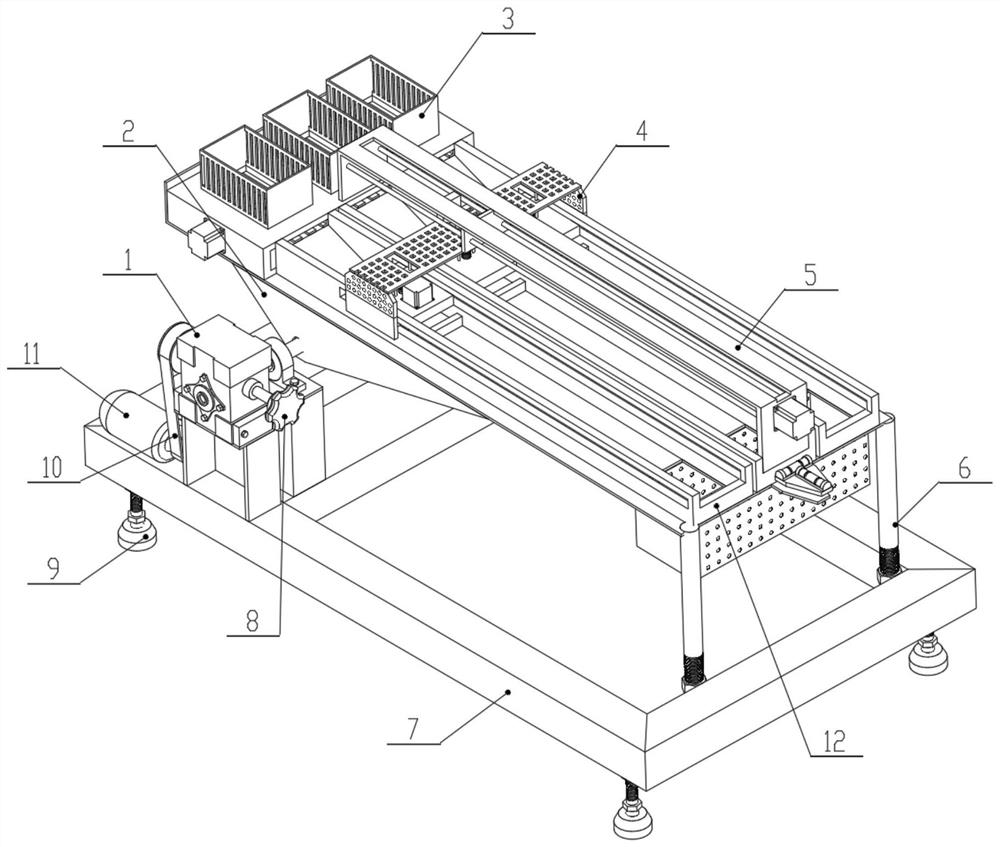

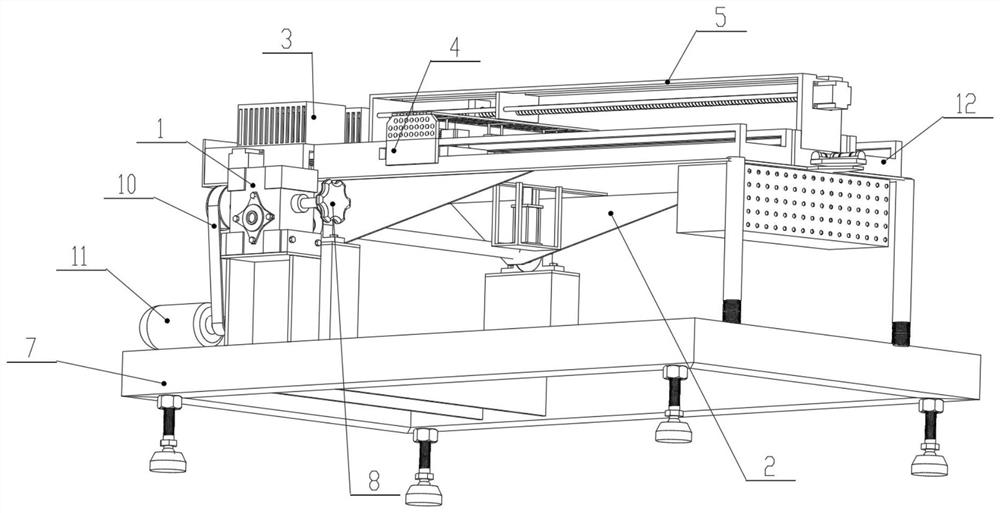

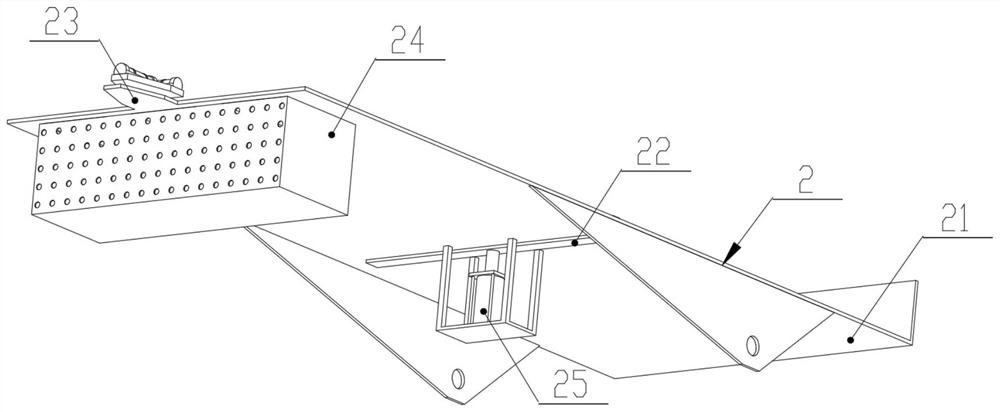

[0048] see figure 1 , image 3 , Figure 5 and Figure 6 , an embodiment provided by the present invention: an anti-slip angle meter, including a worm gear reducer 1, a supporting device 2, a paper feeding device 3, a limiting device 4, a guiding device 5, a connecting screw 6, and a supporting chassis 7 , hand wheel 8, support feet 9, connecting belt 10, servo motor 11 and guide rail 12;

[0049] The four corners of the lower end surface of the support chassis 7 are fixedly equipped with support feet 9 for supporting, and the upper end surface of the support chassis 7 is fixedly installed with a worm gear reducer 1 near the front end. A servo motor 11 is fixedly installed on the front end near the bottom, and the servo motor 11 is meshed with the worm gear reducer 1 through the connecting belt 10. The rear end face of the worm gear reducer 1 is fixedly equipped with a hand wheel 8 and an electronic angle meter. And the side end surface of the worm gear reducer 1 is provid...

Embodiment 2

[0070] On the basis of Example 1, such as Figure 10 As shown, the pushing guide plate 53 includes a supporting spring 531, a baffle plate 532 and a sliding plate 533, and the inner end surface of the sliding plate 533 is fixedly equipped with three groups of supporting springs 531 evenly and equidistantly, and the side ends of the three groups of supporting springs 531 are fixedly connected with Baffle plate 532 .

[0071] During the implementation of this embodiment, when detecting samples of different lengths to be detected, the support motor 51 can drive the sliding plate 533 to move to the front or rear accurately through the limit of the connection screw 54 and the guide slider 55 , to facilitate the positioning of the follow-up threaded slide shaft 46 to the upper center of the sample to be detected, while the support spring 531 and the baffle plate 532 can effectively improve the protection of the limiting device 4 through the action of elastic force, and improve the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com