Working method of movable intelligent butt joint cable reels

A working method and a technology of moving cables, which are applied in the direction of cable laying equipment, etc., can solve the problems that mobile robots cannot carry equipment with too much power, low continuous working ability, synchronization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

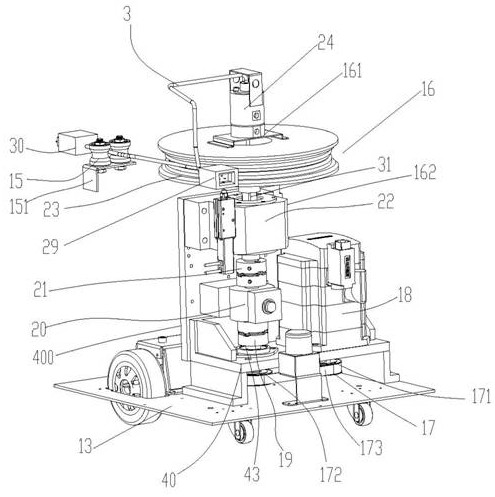

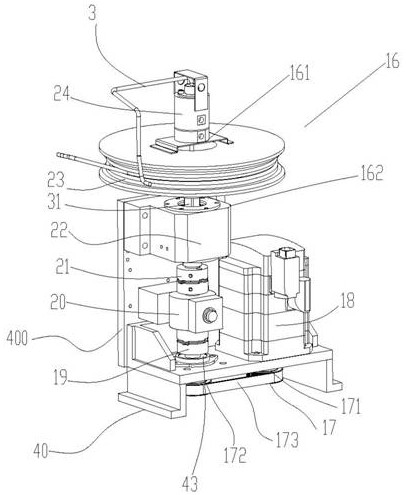

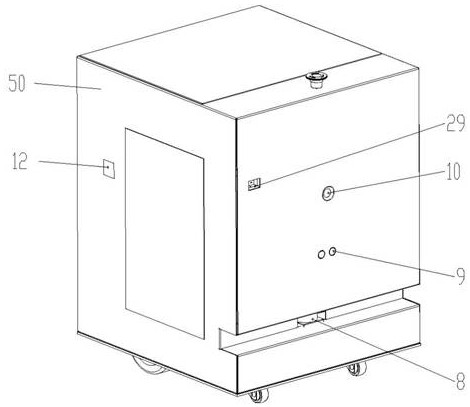

[0040] Such as Figure 1-8 As shown, a movable intelligent docking cable reel includes more than one intelligent mobile cable reel 2, cable rope 3, construction robot 5 and distribution box 1, and each intelligent mobile cable reel 2 is connected to each other through cable rope 3 connected, each of the intelligent mobile cable reels 2 is connected by a cable 3 to form an uninterrupted line, the intelligent mobile cable reel 2 at the front end of the line is connected to the distribution box 1 through the cable 3, and the intelligent mobile cable reel 2 at the end of the line is connected to the distribution box 1 The mobile cable reel is connected to the construction robot 5 through the cable rope 3, and the intelligent mobile cable reel 2 includes a cable reel automatic winding mechanism 16, an external housing 50 and a mobile chass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap