Suspension touch screen and production process thereof

A floating touch, production process technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the touch screen light intensity eye damage, high touch screen replacement price, touch screen Broken screen and other problems, to achieve the effect of simple manufacturing process, soft brightness, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

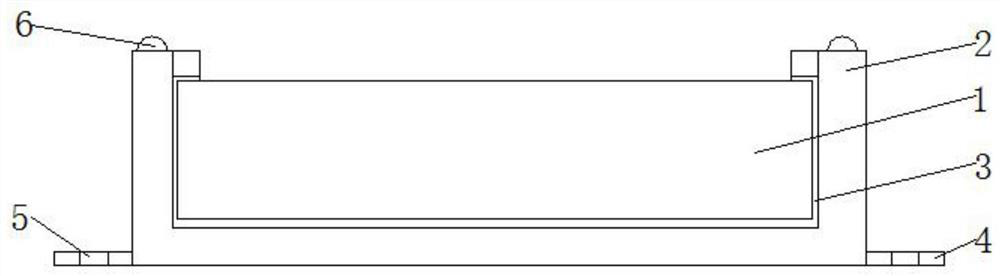

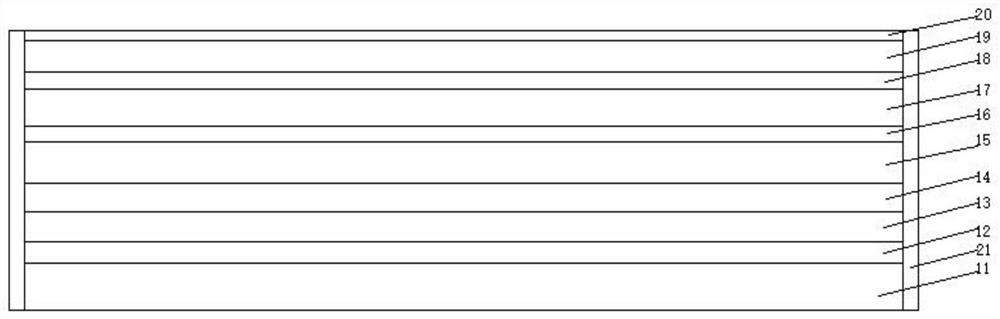

[0021] see Figure 1-2 , the present invention provides a technical solution: a floating touch screen and its production process technical solution, including a touch screen body 1 and a protective frame 2, the inner side of the protective frame 2 is coated with glue 3, the touch screen body 1 Fixedly mounted on the inner side of the protective frame 2 by glue 3, the touch screen body 1 is composed of a display layer 11, a conductive circuit layer 12, a polarizing layer 13, an anti-blue light layer 14, a self-capacitance sensor layer 15, a first shielding layer 16, and an interconnection layer. The capacitive sensor layer 17, the second shielding layer 18, the transparent glass layer 19, the protective film layer 20 and the side shielding layer 21 are composed, the conductive circuit layer 12 is arranged on the top of the display layer 11, and the polarizing layer 13 is arranged on the wire circuit layer 12 At the top, the anti-blue light layer 14 is arranged on the top of the...

Embodiment 2

[0032] see Figure 1-2 , the present invention provides a technical solution: a floating touch screen and its production process technical solution, including a touch screen body 1 and a protective frame 2, the inner side of the protective frame 2 is coated with glue 3, the touch screen body 1 Fixedly mounted on the inner side of the protective frame 2 by glue 3, the touch screen body 1 is composed of a display layer 11, a conductive circuit layer 12, a polarizing layer 13, an anti-blue light layer 14, a self-capacitance sensor layer 15, a first shielding layer 16, and an interconnection layer. The capacitive sensor layer 17, the second shielding layer 18, the transparent glass layer 19, the protective film layer 20 and the side shielding layer 21 are composed, the conductive circuit layer 12 is arranged on the top of the display layer 11, and the polarizing layer 13 is arranged on the wire circuit layer 12 At the top, the anti-blue light layer 14 is arranged on the top of the...

Embodiment 3

[0043] see Figure 1-2 , the present invention provides a technical solution: a floating touch screen and its production process technical solution, including a touch screen body 1 and a protective frame 2, the inner side of the protective frame 2 is coated with glue 3, the touch screen body 1 Fixedly mounted on the inner side of the protective frame 2 by glue 3, the touch screen body 1 is composed of a display layer 11, a conductive circuit layer 12, a polarizing layer 13, an anti-blue light layer 14, a self-capacitance sensor layer 15, a first shielding layer 16, and an interconnection layer. The capacitive sensor layer 17, the second shielding layer 18, the transparent glass layer 19, the protective film layer 20 and the side shielding layer 21 are composed, the conductive circuit layer 12 is arranged on the top of the display layer 11, and the polarizing layer 13 is arranged on the wire circuit layer 12 At the top, the anti-blue light layer 14 is arranged on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com