Self-rotating blowing type ash removal device for observation window of coal feeder

A technology of cleaning device and observation window, which is applied in the direction of cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., which can solve the problems of affecting the normal operation of the unit to generate electricity, delaying the timing of troubleshooting, and losing the coal feeder Monitoring functions and other issues, to achieve ideal cleaning effect, improve reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 - connection purge treatment:

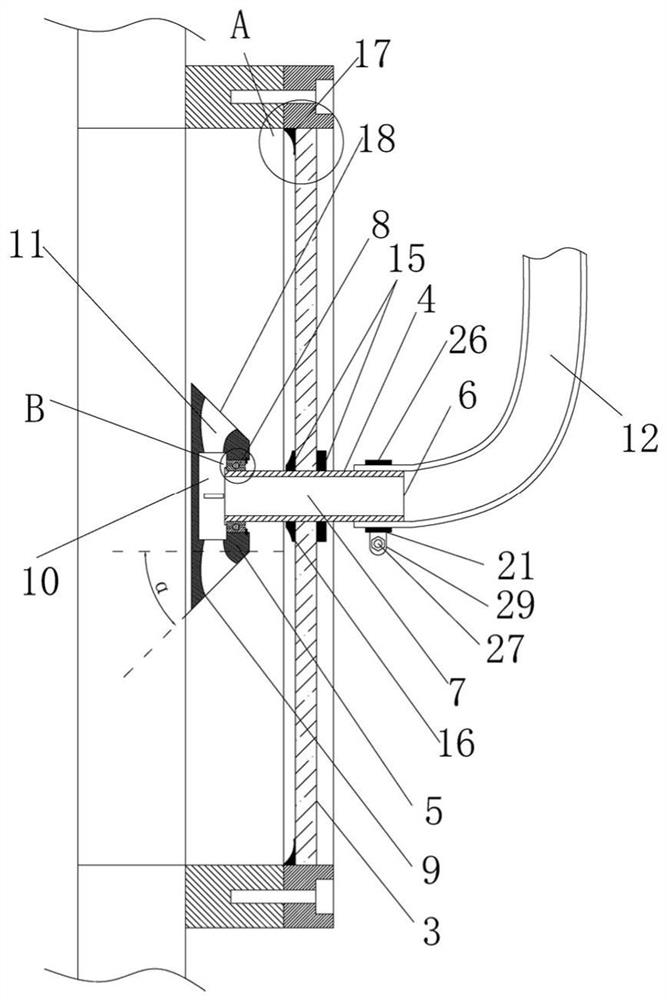

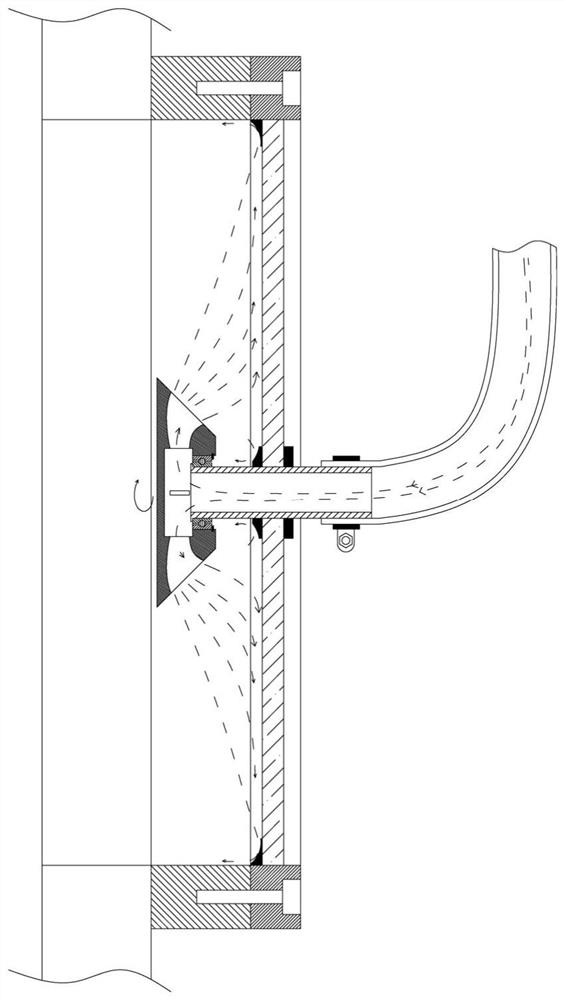

[0061] Such as Figure 2-5 As shown, when assembling the self-rotation purge type dust cleaning device, the connecting wall of the self-rotation purge part 5 of the present invention and the outer connection wall of the rotation connection part 8 are interference fit, and the connection of the self-rotation purge part 5 There is a snap ring installation groove 24 above the wall, and a snap ring 22 is horizontally arranged in the snap ring installation groove 24. The lower end surface of the snap ring 22 is pressed against the outer upper end surface of the rotating connection part 8, and the snap ring 22 It can further improve the fixing effect of the connection position between the rotation purge part 5 and the rotation connection part 8, and effectively avoid the displacement or loosening of the rotation purge part 5 due to the force of the airflow during the blowing process, so The outer wall of the purging connecting shaft ...

Embodiment 2

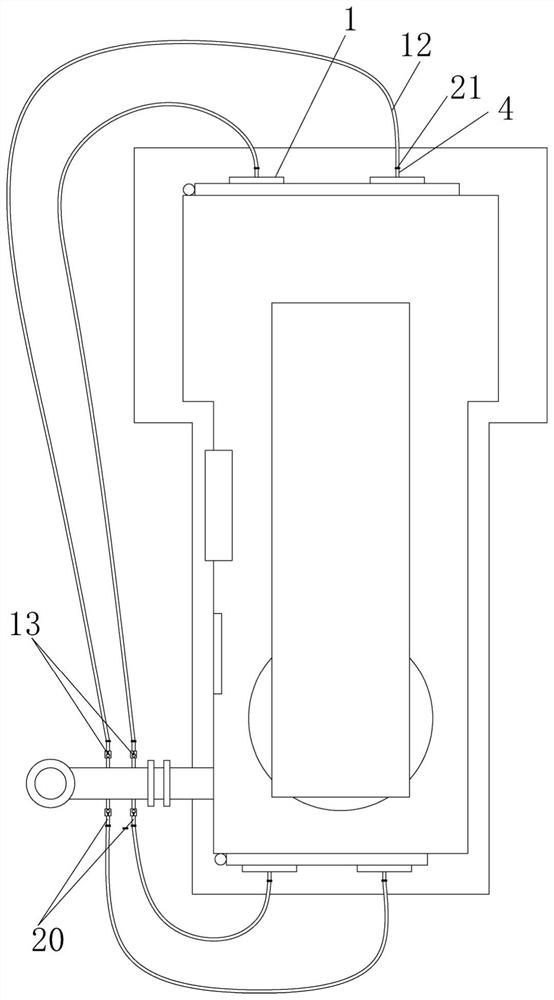

[0069] Such as Figure 8-11 As shown, this embodiment is similar to Embodiment 1, the difference is that in this embodiment, as Figure 8 As shown, when connecting the self-rotating purge mechanism and the air supply mechanism, it is only necessary to set up a sealed air supply branch pipe 14, install the control valve 13 on the sealed air supply branch pipe 14, and install the control valve 13 on the sealed air supply branch pipe 14. The front end is connected with a multi-port branching pipe 20, and the front end of the multi-port branching pipe 20 is provided with four branching nozzles 28, and the branching nozzles 28 of the multi-port branching pipe 20 are connected with the air inlet end of the air supply conduit 12, through the locking part 21 After the locking and fixing operation is completed, the locking collar 26 is set on the outer wall of the air supply conduit 12, and then the locking blocks 29 at both ends of the locking collar are locked by the locking connecti...

Embodiment 3

[0072] Embodiment 3 - Overhaul and maintenance treatment:

[0073] Such as Figure 1-2 As shown, when the device is shut down or used for a long time, it is necessary to disassemble and repair the coal feeder observation window of the present invention when the self-rotating purge type ash removal device. First close all the control valves 13, then loosen the locking part 21, then open the observation window, take out the upper sealing fastening ring 15, pull out the self-rotating purge mechanism from the bottom of the observation glass 2, and then clean up or replace.

[0074] In the present invention, the air supply conduit 12 is preferably made of a translucent hose. During the air supply process, the operator can intuitively observe the internal circulation of the air supply conduit 12. Once a blockage occurs, it can be quickly closed and cleared.

[0075] Through the self-rotating purge type ash cleaning device of the present invention, when the coal feeder is shut down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com