Rotary sliding type copper alloy pipe extrusion device

An extrusion device, copper alloy technology, applied in metal extrusion, indenter/punch, metal processing equipment, etc., can solve the problems of low operation efficiency, inflexible use, inconvenient replacement of extrusion plates, etc., to achieve stable Good performance, increase the squeeze space, the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

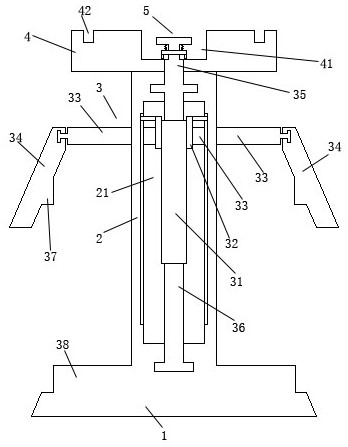

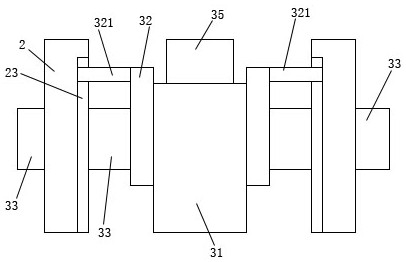

[0025] Such as Figures 1 to 7 As shown, a rotary-sliding copper alloy pipe extrusion device includes an extrusion plate 1, a positioning column 2, a rotary sliding assembly 3, and a pushing flange 4; Connecting rod 33, floating sleeve 32, built-in screw rod 31, drive rod 35, separation column 36, external thread column 38, internal thread ring body 37; The positioning column 2 is installed in the middle of the upper end; the upper end of the positioning column 2 is installed with a push flange 4; the inside of the positioning column 2 is provided with a floating cavity 21 distributed from top to bottom; the middle of the two sides of the floating cavity 21 There are piercing openings 24 distributed from top to bottom respectively; the built-in screw 31 is rotatably clamped and installed in the middle of the floating cavity 21; the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com