Paper bag flat rope externally-attached handle conveying device

A technology of conveying device and sticking handle, applied in the directions of transportation and packaging, packaging, papermaking, etc., can solve the problems of reducing paper cost and production cost, unstable finger claws biting the flat rope, affecting the stable work of the machine, etc., to avoid flattening. Rope jamming, reliable conveying, reliable effect of action execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the conveying device for attaching the handle of the paper bag flat rope to the outside of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

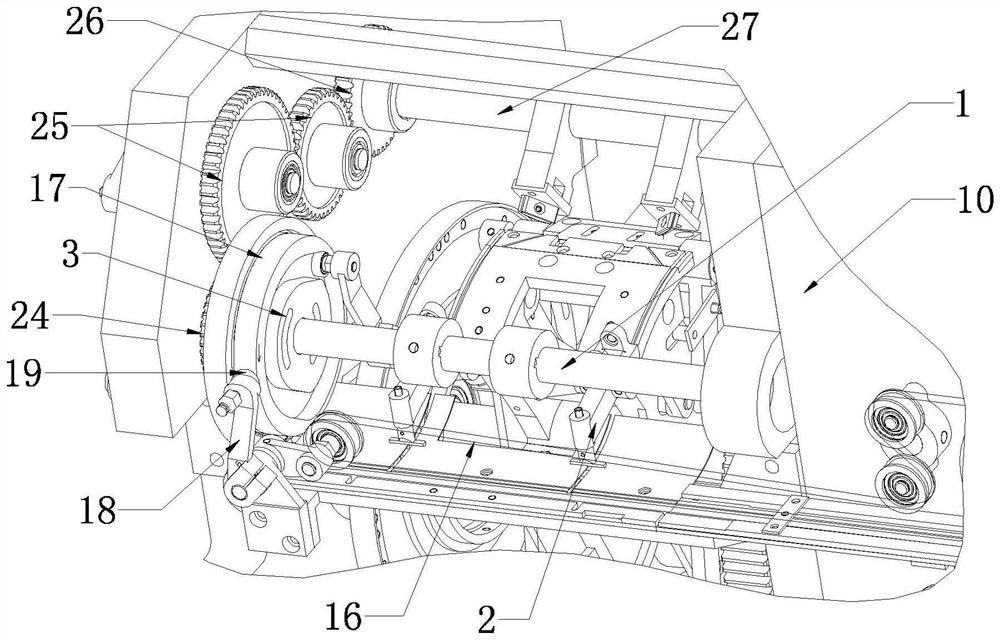

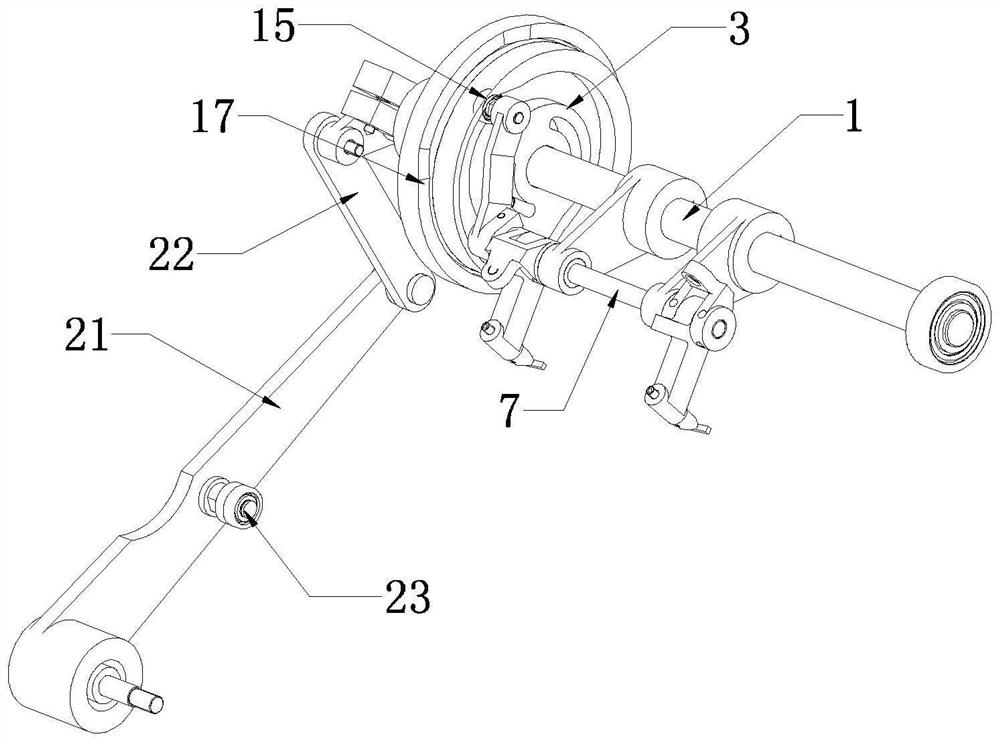

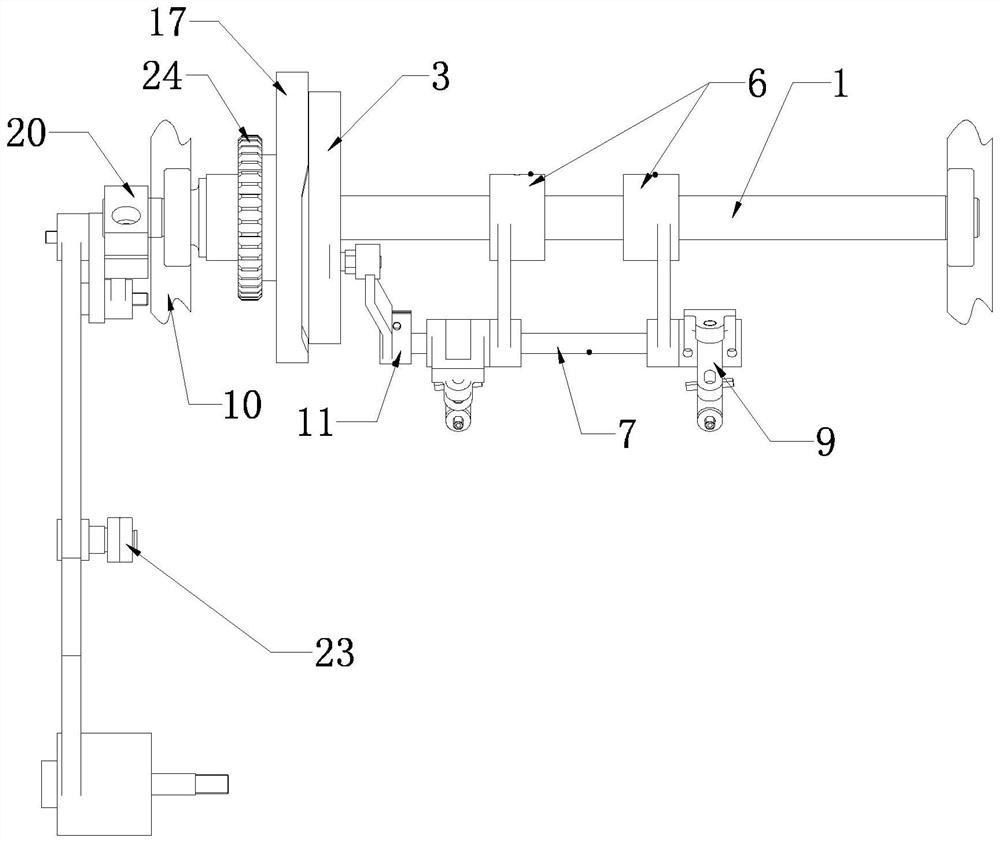

[0027] As shown in the figure, the paper bag flat rope external handle conveying device of the present invention includes two left and right wall panels 10, a main shaft 1 installed between the left and right two wall panels 10 through bearings, and a pin insertion mechanism 2 fixedly installed on the main shaft , the main shaft 1 is covered with a pin swing device 3 for driving the swing of the pin mechanism, which is composed of figure 2 , image 3 , Image 6 It can be seen that the pin insertion mechanism 2 includes a pair of fixed bases 6 with mounting sleeves 5 fixedly installed on the main shaft 1, a connecting shaft 7 installed through two mounting sleeves, and two connecting shafts with insertion sleeves installed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com