Weft-knitted double-sided four-way stretch fabric and preparation method thereof

A four-sided elastic and double-sided technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of easy color difference, inaccurate color, poor air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

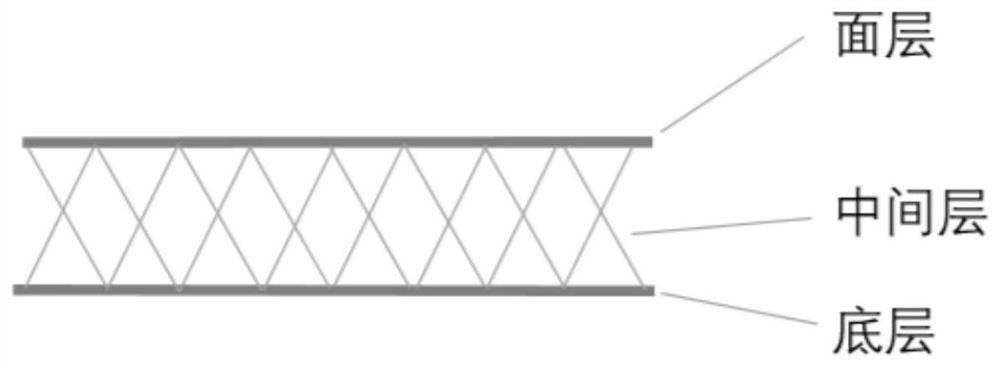

[0031] This embodiment provides a weft-knitted double-sided four-way elastic fabric, which includes a surface layer, a bottom layer and an intermediate layer connecting the surface layer and the bottom layer;

[0032] The surface layer comprises the first spinning yarn and the second spinning yarn, wherein, the first spinning yarn is cotton yarn with a yarn count of 44 British counts, and the second spinning yarn is spandex elastic yarn with a yarn count of 30D;

[0033] The bottom layer includes the third spinning yarn and the fourth spinning yarn, wherein the third spinning yarn is chemical fiber filament with a yarn count of 75D / 36F, and the fourth spinning yarn is spandex elastic yarn with a yarn count of 20D;

[0034] The surface layer and the bottom layer are connected by a connecting yarn, and the connecting yarn is connected to the first spinning yarn and the third spinning yarn, wherein the connecting yarn is a chemical fiber filament, and the yarn count is 30D / 12F;

...

Embodiment 2

[0061] This embodiment provides a weft-knitted double-sided four-way elastic fabric, which includes a surface layer, a bottom layer and an intermediate layer connecting the surface layer and the bottom layer;

[0062] The surface layer comprises the first spinning yarn and the second spinning yarn, wherein, the first spinning yarn is cotton yarn with a yarn count of 44 British counts, and the second spinning yarn is spandex elastic yarn with a yarn count of 30D;

[0063] The bottom layer includes the third spinning yarn and the fourth spinning yarn, wherein the third spinning yarn is chemical fiber filament with a yarn count of 75D / 36F, and the fourth spinning yarn is spandex elastic yarn with a yarn count of 20D;

[0064] The surface layer and the bottom layer are connected by a connecting yarn, and the connecting yarn is connected to the first spinning yarn and the third spinning yarn, wherein the connecting yarn is a chemical fiber filament, and the yarn count is 30D / 12F;

...

Embodiment 3

[0091] This embodiment provides a weft-knitted double-sided four-way elastic fabric, which includes a surface layer, a bottom layer and an intermediate layer connecting the surface layer and the bottom layer;

[0092] The surface layer comprises the first spinning yarn and the second spinning yarn, wherein, the first spinning yarn is cotton yarn with a yarn count of 44 British counts, and the second spinning yarn is spandex elastic yarn with a yarn count of 30D;

[0093] The bottom layer includes the third spinning yarn and the fourth spinning yarn, wherein the third spinning yarn is chemical fiber filament with a yarn count of 75D / 36F, and the fourth spinning yarn is spandex elastic yarn with a yarn count of 20D;

[0094] The surface layer and the bottom layer are connected by a connecting yarn, and the connecting yarn is connected to the first spinning yarn and the third spinning yarn, wherein the connecting yarn is a chemical fiber filament, and the yarn count is 30D / 12F;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com