Small gas turbine rack

A gas turbine and bench technology, which is applied to gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of difficulty in realizing free adjustment of horizontal position, reducing the installation efficiency of gas turbines, and inconvenient centering work, and the installation method is simple and fast. , The effect of convenient operation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

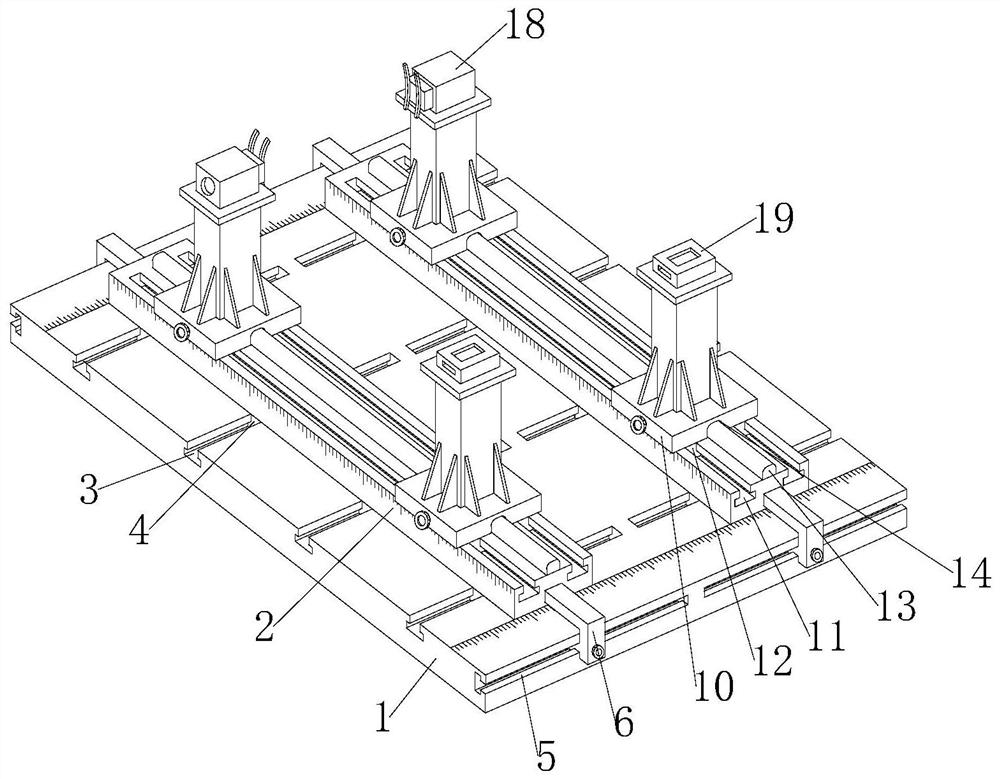

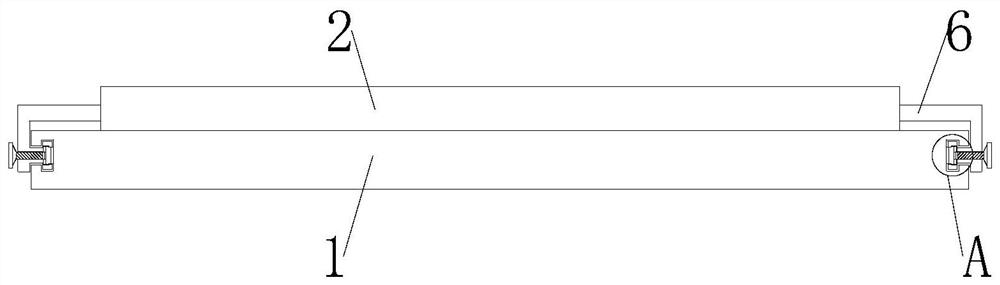

[0024] see Figure 1 to Figure 4 :

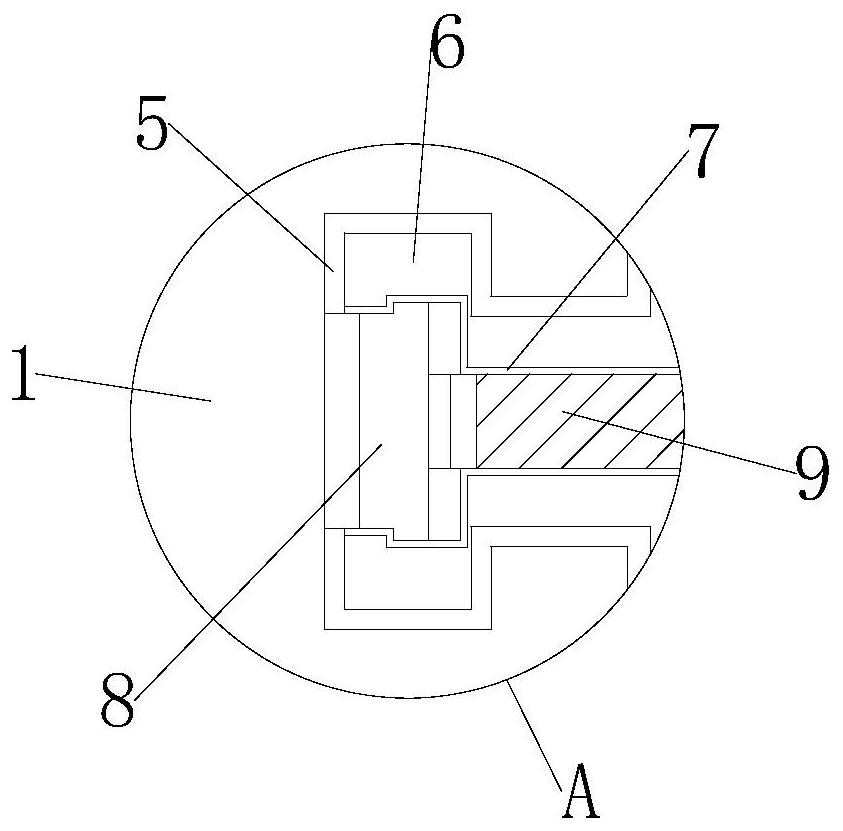

[0025] A small gas turbine stand, including a base 1, an adjustment plate 2 and an adjustment block 10;

[0026] Adjusting plate 2 is provided with two pieces, and two adjusting plates 2 are symmetrically arranged on the front and rear sides above the base 1, and the front and rear ends of the left and right sides of the base 1 are all provided with chute 3 5, and the left and right ends of the adjusting plate 2 are fixed with The sliding frame 6 connected by the chute three 5, the outer side of the sliding frame 6 is penetrated with a groove one 7, the inner end of the groove one 7 is provided with a top block one 8, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com