Kitchen waste treatment and biological breeding production line

A technology for kitchen waste and waste treatment equipment, which is applied in the directions of transportation and packaging, chemical instruments and methods, and solid waste removal, etc., to achieve the effects of improving the breeding effect, improving the service life, and improving the utilization rate of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

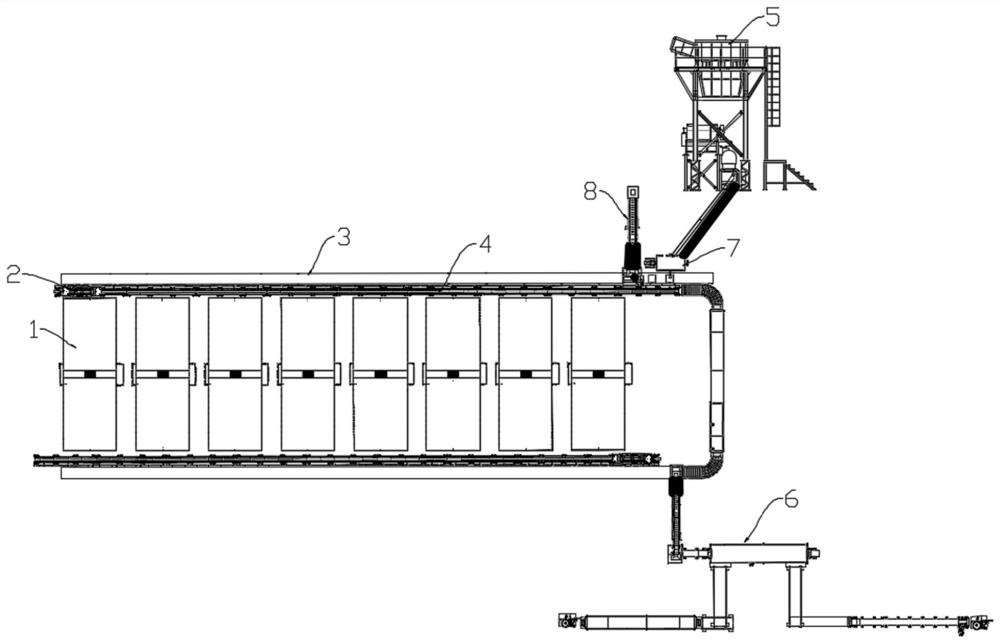

[0049] A food waste treatment and biological breeding production line, which can process the collected food waste and prepare feed for biological breeding, then send the breeding box with feed and larvae into the breeding warehouse, and finally feed the cultured larvae And the remaining organic fertilizer is processed to realize a fully automated assembly line from kitchen waste treatment to biological breeding. The specific structure and working principle are described in detail below.

[0050] Such as figure 1 As shown, the production line mainly includes garbage disposal equipment 5, stirring device 7, larva adding device 8, biological breeding system, post-processing system 6 and automatic control system.

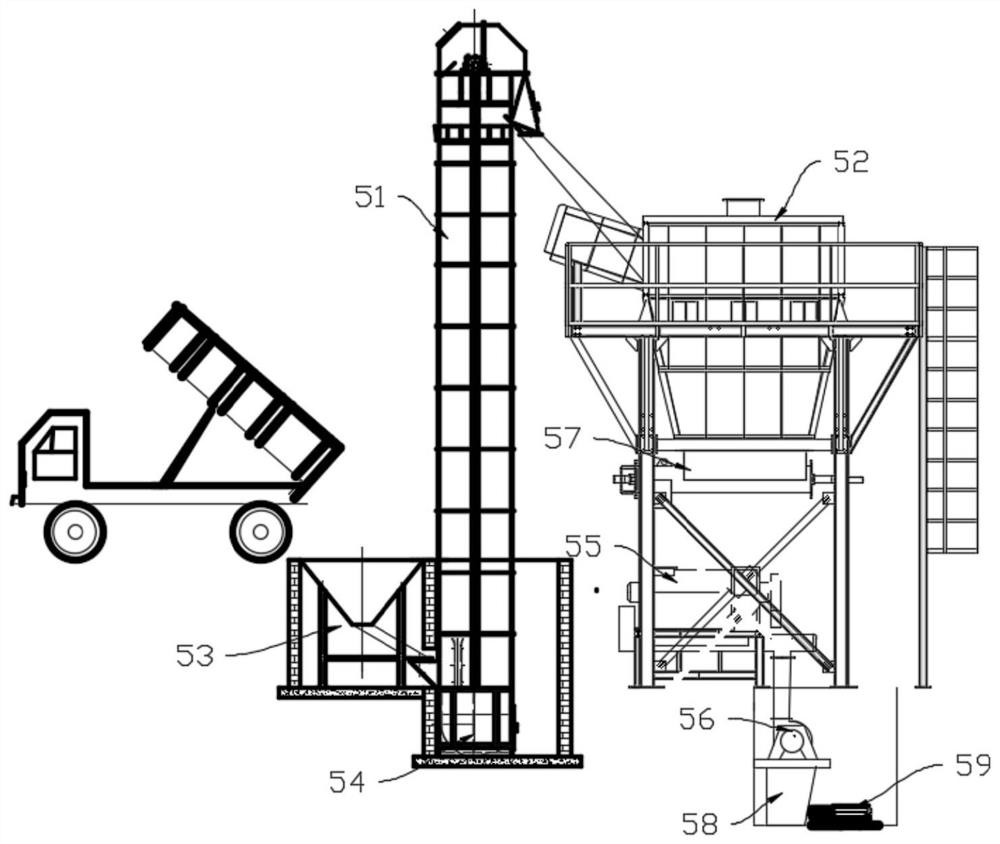

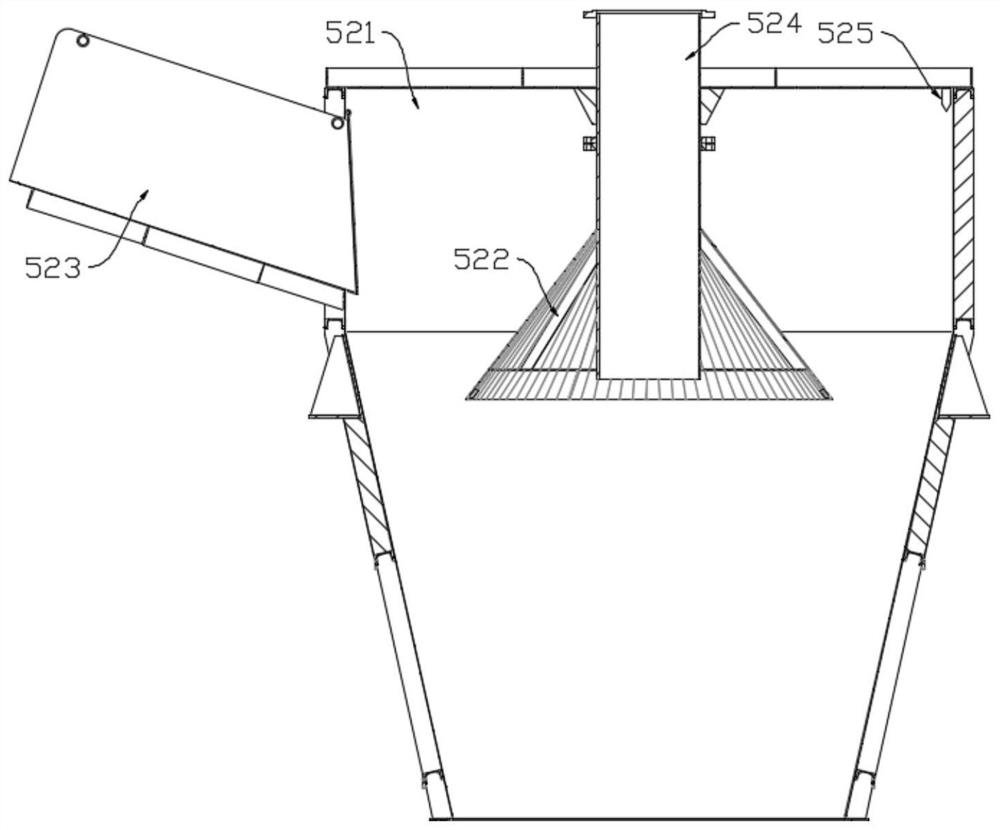

[0051] Among them, such as figure 2 As shown, the garbage treatment equipment 5 includes a conveying device 51 , a hopper 52 , a pulping device, a filtering device 53 and a swill collecting tank 54 . Wherein, the outlet of the feeding device 51 is connected to the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap