Rotary tool head and floating device

A technology of floating devices and rotating tools, which is applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc. It can solve the problems of low tool head life, reduce flash, avoid vibration and wear, and facilitate installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

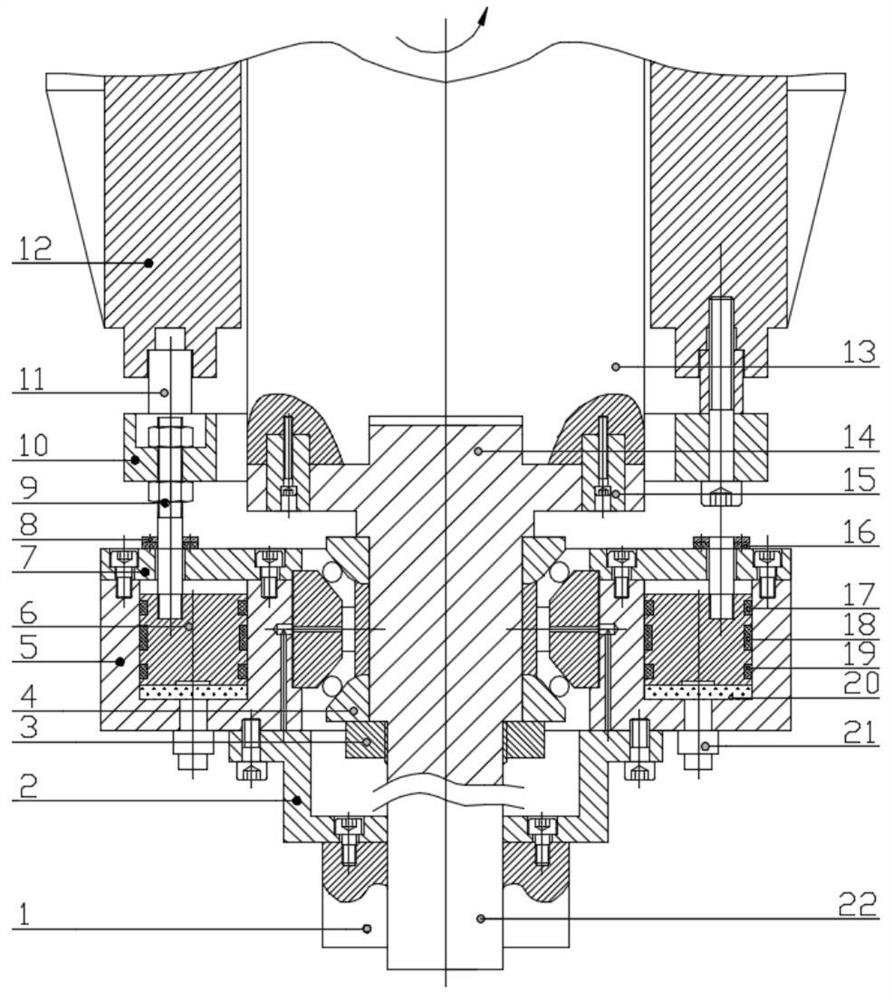

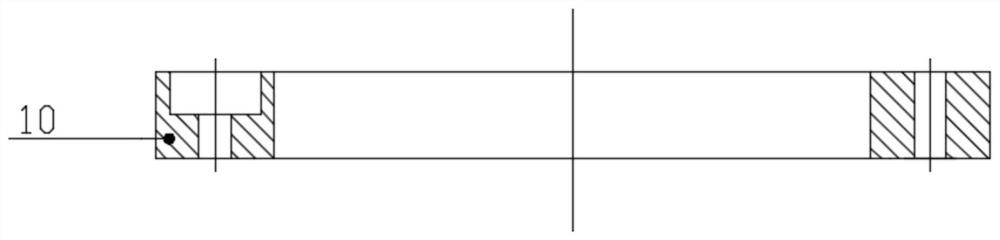

[0027] like Figure 1-8 As shown, a rotating tool head and its floating device include a mold base structure, a rotating structure and a tool head 22, the rotating structure drives the tool head 22 to rotate, and the rotating structure includes a rotating mechanism 13 and a transmission shaft 14, The lower end surface of the rotating mechanism 13 is screwed to the transmission key 15, and the transmission key 15 is used to drive the transmission shaft 14 to rotate. The upper end surface of the transmission shaft 14 is axially separated from the lower end surface of the rotation mechanism 13 and leaves a certain The gap is for the transmission shaft 14 to move in the axial direction. The transmission shaft 14 is connected to the tool head 22, and both are solid structures. The outer side of the transmission shaft 14 is sleeved with a floating structure, and the floating The structure is connected to the formwork structure, the transmission shaft 14 and the tool head 22 move in ...

Embodiment 2

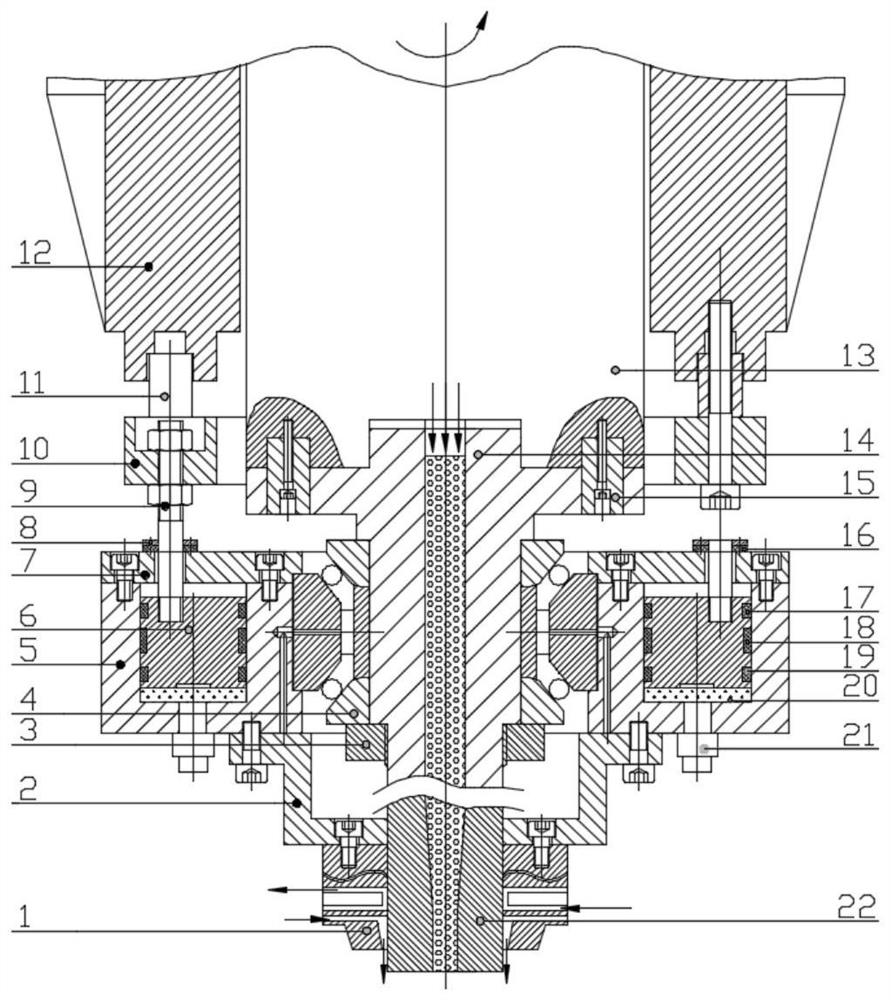

[0037] like figure 2 As shown, referring to the rotary tool head and its floating device in Embodiment 1, the rotary mechanism 13, the transmission shaft 14 and the tool head 22 are hollow structures connected with each other, and the outer side of the tool head 22 is pierced with an annular shell 1, A cooling water system and a gas protection system are arranged in the annular housing 1, the cooling water system includes a water inlet and a water outlet, the water flows around the tool head 22, the gas protection system includes an air inlet and an air outlet, The air outlet faces the working direction of the tool head 22 and is used for cooling the tool head 22 and preventing the influence of oxidation inclusions. The annular housing 1 , the fixed ring 2 and the annular cylinder 5 are connected into one body.

[0038] The tool head 22 is a hollow structure, suitable for friction additives, and its working process includes the following stages:

[0039] (1) Preparatory stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com