Automatic assembling mechanism for automobile parts

A technology for auto parts and automatic assembly, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of slow visual inspection, low assembly efficiency, and inconsistency in size, etc., to achieve lower detection risks, simple assembly methods, and improved The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solution of the invention with reference to the accompanying drawings of the embodiments of the invention.

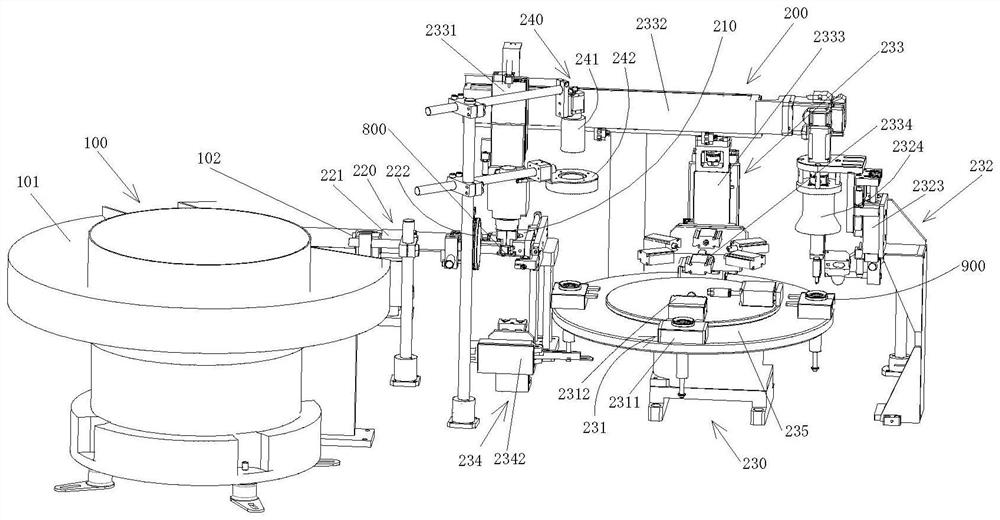

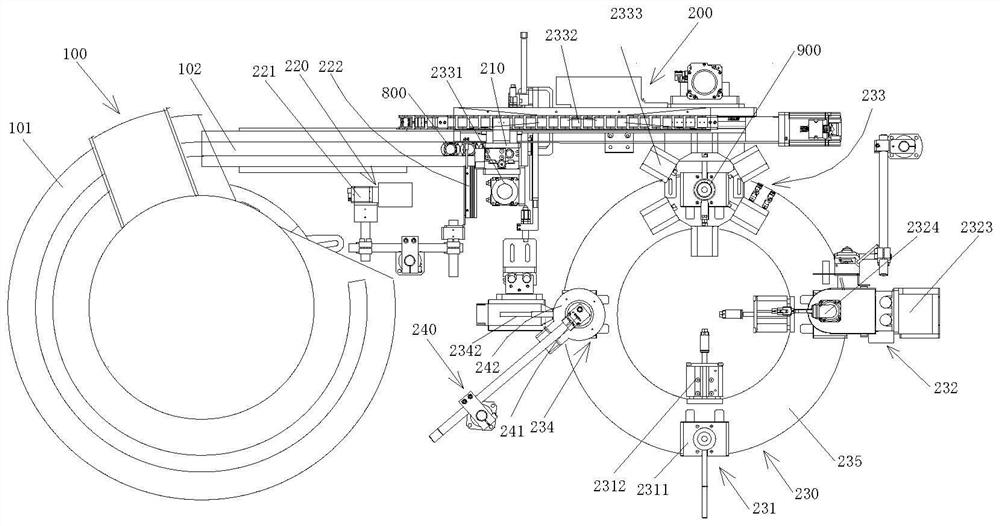

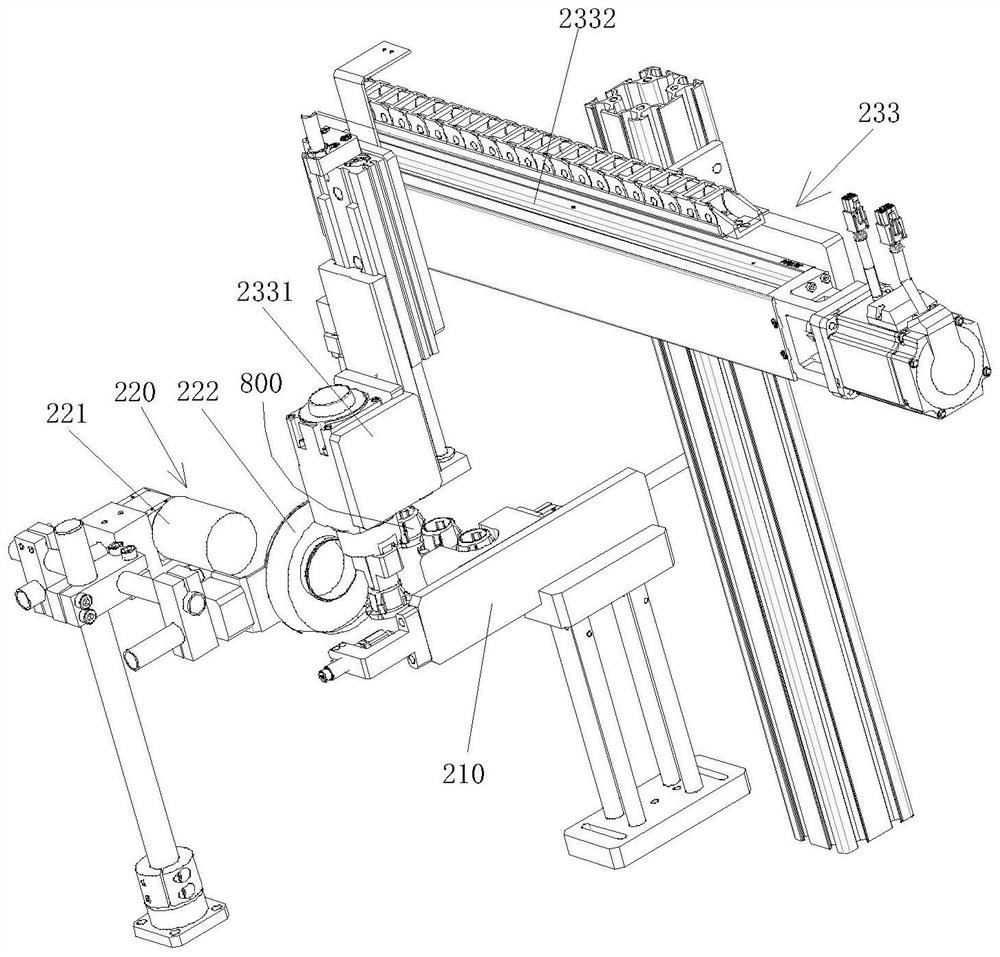

[0037] Such as Figure 1 to Figure 9 Shown is the automatic assembly mechanism for auto parts according to an exemplary embodiment of the present invention, which is used for automatic assembly of buckle 800 and sealing sleeve 900 in auto parts, and its improvement is to include: feeding assembly 100, working mechanism 200 and an external processor mechanism; the feeding assembly 100 is used to deliver the buckle 800 with two or more bayonet openings 820 to the working mechanism 200; the working mechanism 200 is used to detect the buckle 800 and the sealing sleeve 900, and the buckle The buckle 800 is assembled with the sealing sleeve 900; the external processor mechanism is used to compare and process the buckle 800 and the sealing sleeve 900 detected and transmitted by the working mechanism 200 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com