Totally-enclosed flow guide device for pantograph area of high-speed train

A fully enclosed, flow-guiding device technology, applied in the direction of railway car body, transportation and packaging, railway car body parts, etc., can solve problems such as aerodynamic noise and aerodynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] Aiming at the problems of aerodynamic resistance and aerodynamic noise caused by the existing pantograph, the invention provides a fully enclosed flow guide device in the pantograph area of a high-speed train.

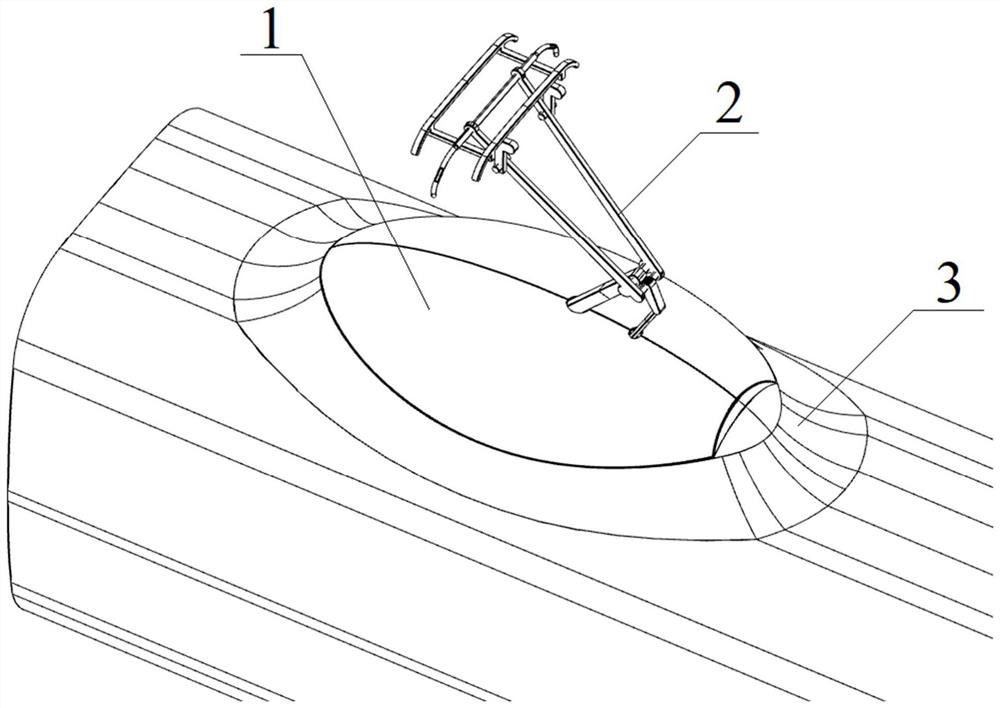

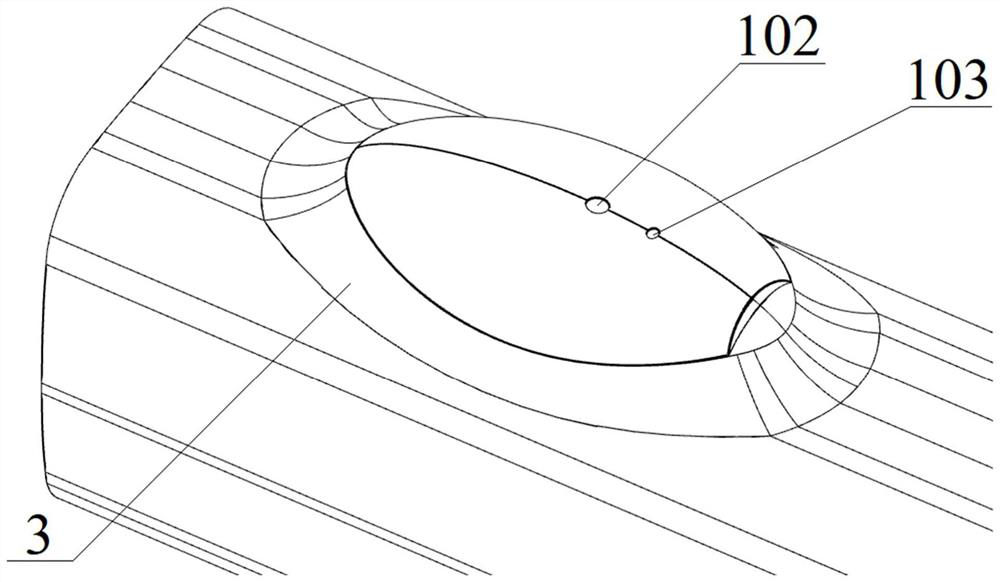

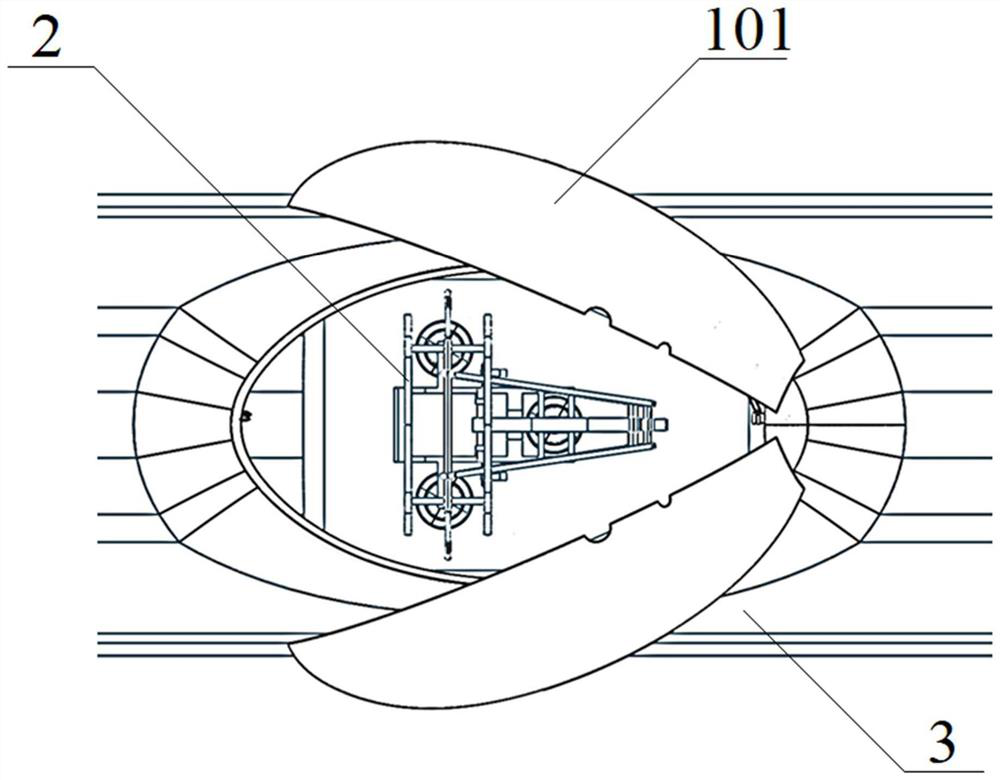

[0031] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a fully-enclosed deflector for the pantograph area of a high-speed train, comprising: a deflector 1, the deflector 1 is symmetrically provided with two side wings 101, and the deflector 1 is arranged in a streamlined circular arch or drop shape. The middle part of the wind deflector 1 is provided with a lower arm frame hole 102 and a tie rod hole 103. The pantograph 2 is arranged in the wind deflector 1. The lower arm frame hole 101 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com