Double-rocker-arm cutting-off mechanism for braiding connecting piece of circulator plastic package shell

A technology of cutting mechanism and connecting piece, which is applied in the directions of cutting and unpacking, unpacking of objects, and sending objects. It can solve problems such as low extraction efficiency and structural damage to products, and achieve the effect of improving breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

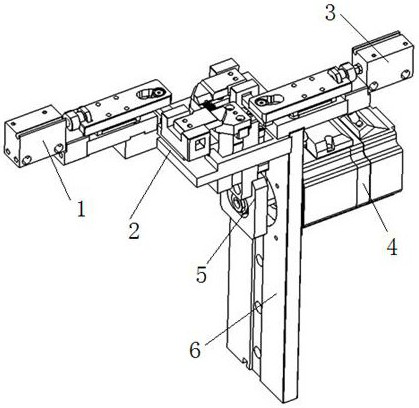

[0020] see figure 1 , a double-rocker arm cutting mechanism for a circulator plastic-encapsulated shell braided with a connecting piece, including a left rocker arm mechanism 1, a left rocker arm fixing seat 2, a right rocker arm mechanism 3, an eccentric drive motor 4, an eccentric up-and-down movement mechanism 5 and a mounting stand plate 6, wherein, the left rocker arm mechanism 1 is installed on the left rocker arm fixing seat 2, the right rocker arm mechanism 3 is installed on the installation vertical plate 6, and the eccentric drive motor 4 is installed on the installation vertical plate 6, and is connected with The eccentric up and down movement mechanism 5 is connected;

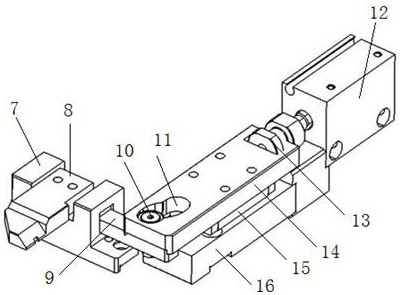

[0021] In this embodiment, the structures of the left rocker mechanism 1 and the right rocker mechanism 3 are as follows: figure 2 As shown, it is connected by upper rocker arm guide seat 7, upper rocker arm 8, upper rocker arm installation strip 9, cam follower 10, cam follower installation groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com