Impressed current cathodic protection local repair device of floating platform and repair method thereof

A floating platform, cathodic protection technology, applied in the field of marine metal anticorrosion, can solve the problems of different protection currents, pollution, marine environment damage, etc., to reduce the risk of operation, reduce operation time, and ensure the effect of personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Sacrificial anode failure due to ship collision, exhaustion of the anode itself or the surface of the sacrificial anode covered with marine organisms;

[0090] The reliability of the device is verified by simulating the actual sea state test on the scale model, and controlling the on-off of the sacrificial anode and the platform by changing the electrical connection between the sacrificial anode and the model platform to simulate the shedding of the sacrificial anode. The specific repair steps are as follows:

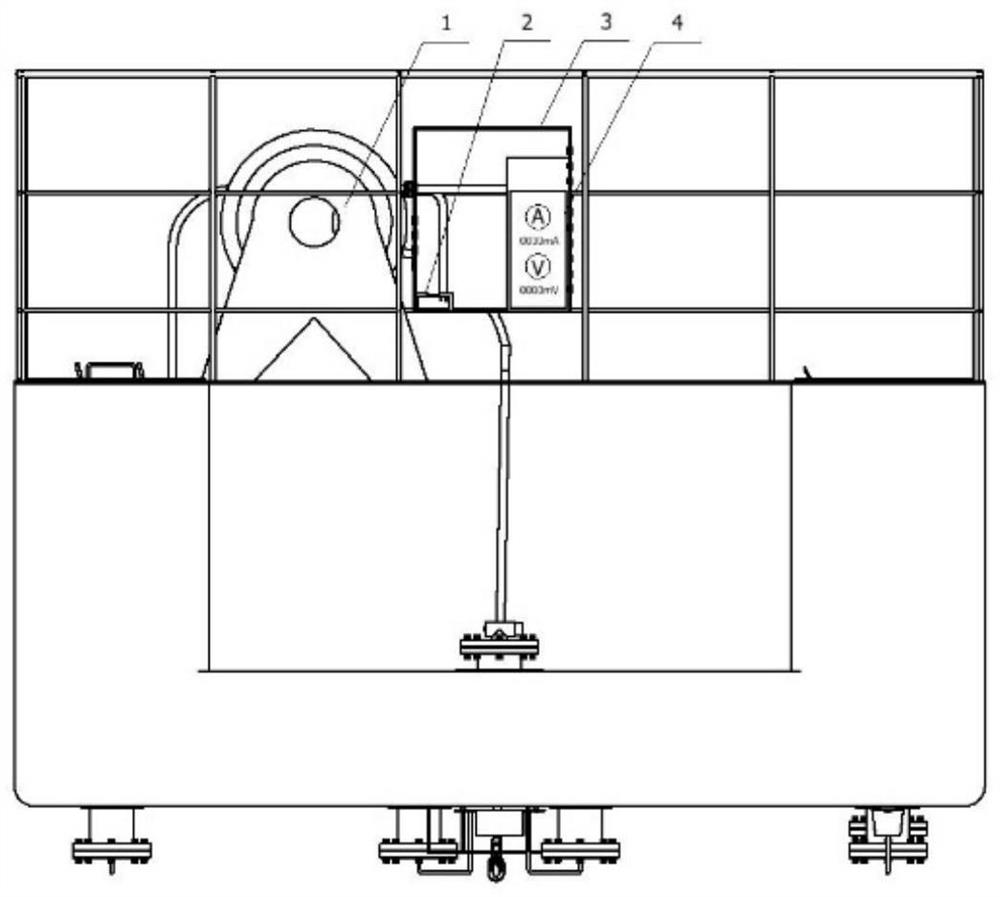

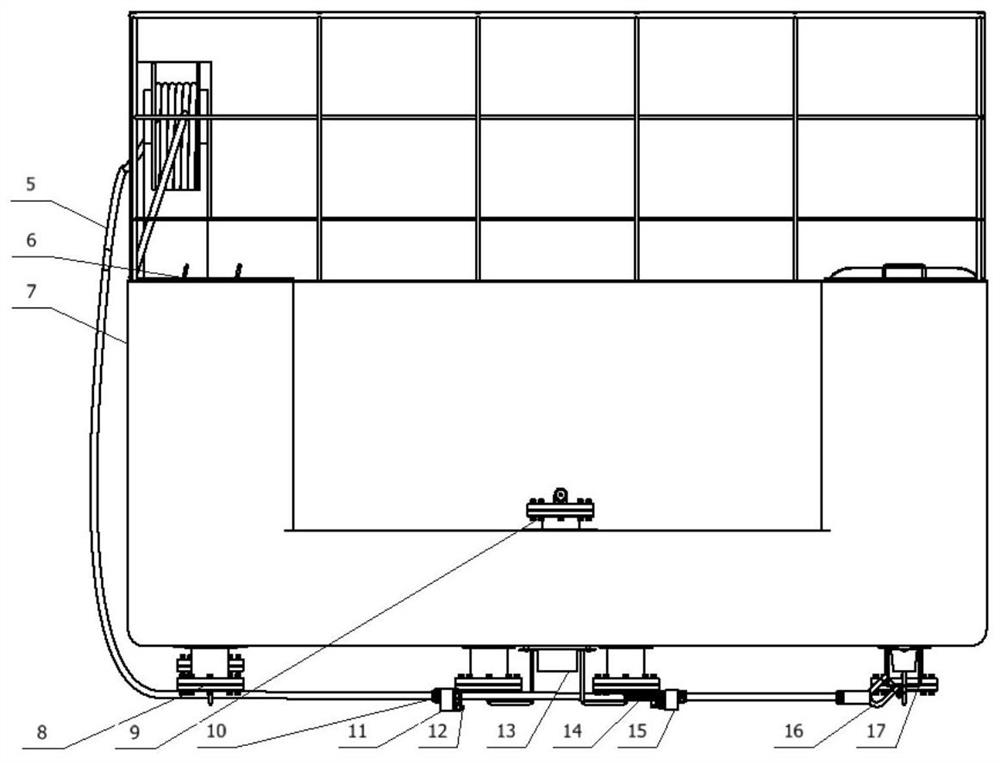

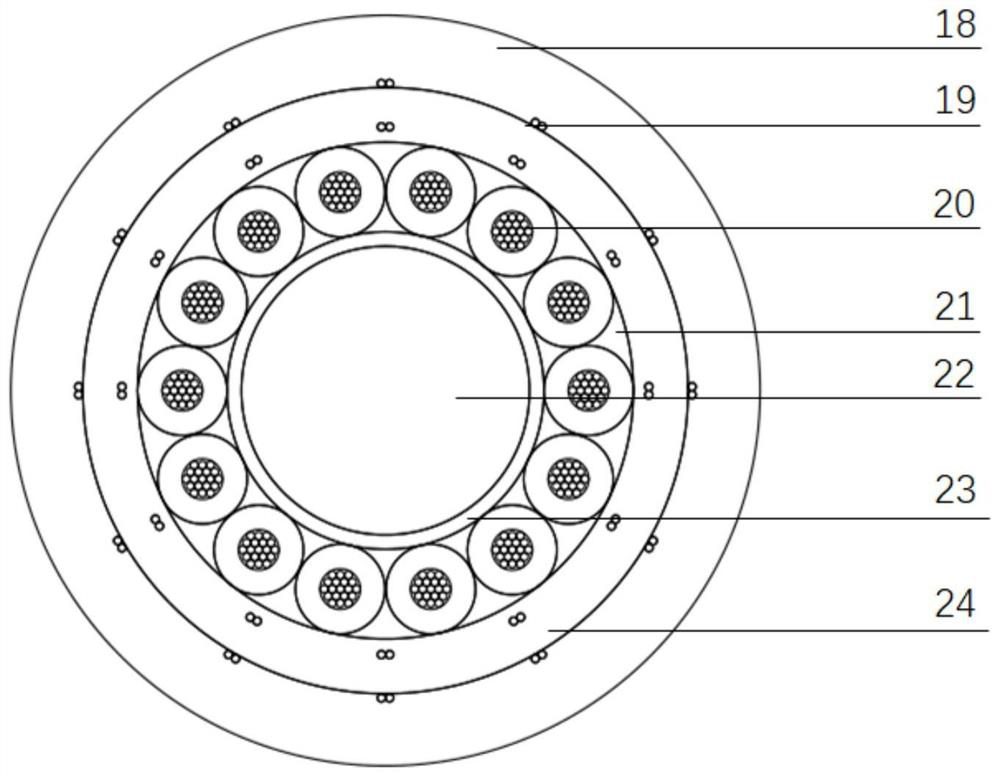

[0091] 1. At this time, the overall potential of the platform is monitored by the potential monitor 4 installed on the ocean floating platform 7, and the real-time feedback information through the potential monitoring software finds that the potential near the sacrificial anode of the platform is -950mV (Ag / AgCl). The electrical connection between the anode and the platform was disconnected, and the potential near the sacrificial anode was found to be -745mV (Ag / ...

Embodiment 2

[0097] Due to the collision of ships, the aging and peeling of the coating itself, and the super typhoon, the local coating on a certain part of the surface of the floating platform is damaged;

[0098] By simulating the actual sea state test on the scale model, the platform damage rate is preliminarily assumed to be 32%, that is, a large area falls off, to verify the reliability of the device. The specific repair steps are as follows:

[0099] 1. At this time, the overall potential of the platform is monitored through the potential monitor 4 installed on the marine floating platform 7, and the information is fed back in real time through the potential monitoring software. It was found that the potential distribution of the whole platform was between -700 and -750mV. At this time, the potential monitor 4 would alarm. The software judged the location of the coating damage through calculation. Personnel entered the water to check to determine the damage of the coating, and desig...

Embodiment 3

[0105] Due to the collision of ships, the aging and peeling of the coating itself, and the super typhoon, the partial coating on the surface of the floating platform was damaged; due to the collision of ships, the exhaustion of the anode itself, or the surface of the sacrificial anode was covered with marine organisms, the sacrificial anode failed.

[0106] By simulating the actual sea state test on the scale model, the damage rate of the platform is preliminarily assumed to be 4%, that is, the local small area falls off, and the sacrificial anode of the test platform is closed, that is, the sacrificial anode fails to verify the reliability of the device; the specific repair Proceed as follows:

[0107] 1. At this time, the overall potential of the platform is monitored by the potential monitor 4 installed on the marine floating platform 7, and the information is fed back in real time through the potential monitoring software; it is found that the potential distribution of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com