Cast-in-place pile over-filling prevention device and using method of device

A cast-in-situ pile and anti-overrunning technology, which is applied in the direction of sheet pile wall, foundation structure test, construction, etc., can solve the problems of high cost, insufficient measurement accuracy, and improved operation requirements, and achieve accurate and timely results, simple device structure, and measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

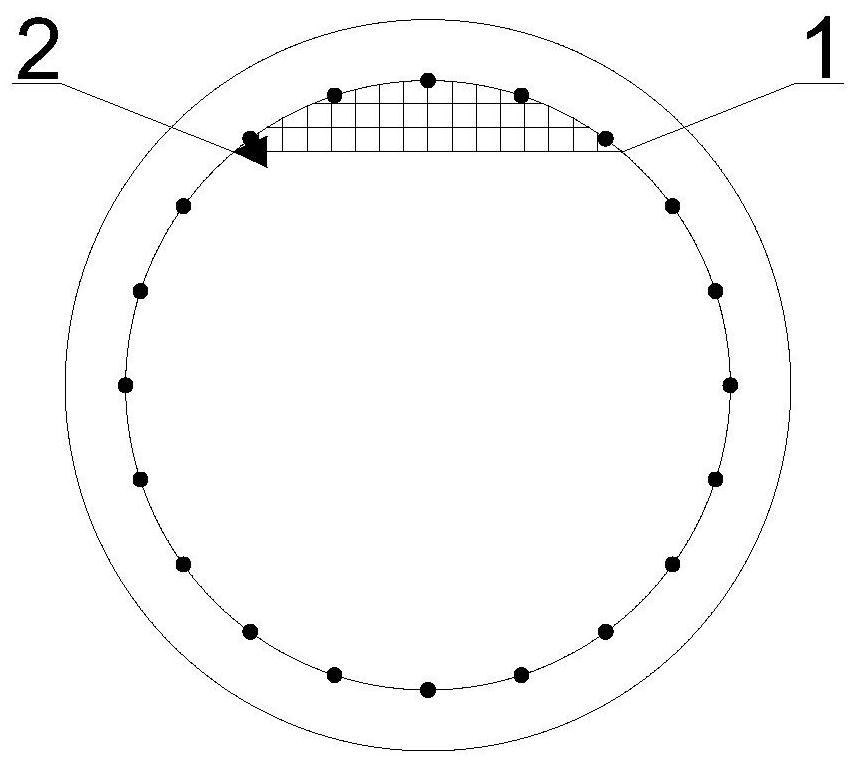

[0027] Such as figure 1 As shown, a device for preventing overfilling of cast-in-situ piles includes a metal mesh 1 and a triangular steel sheet 2 .

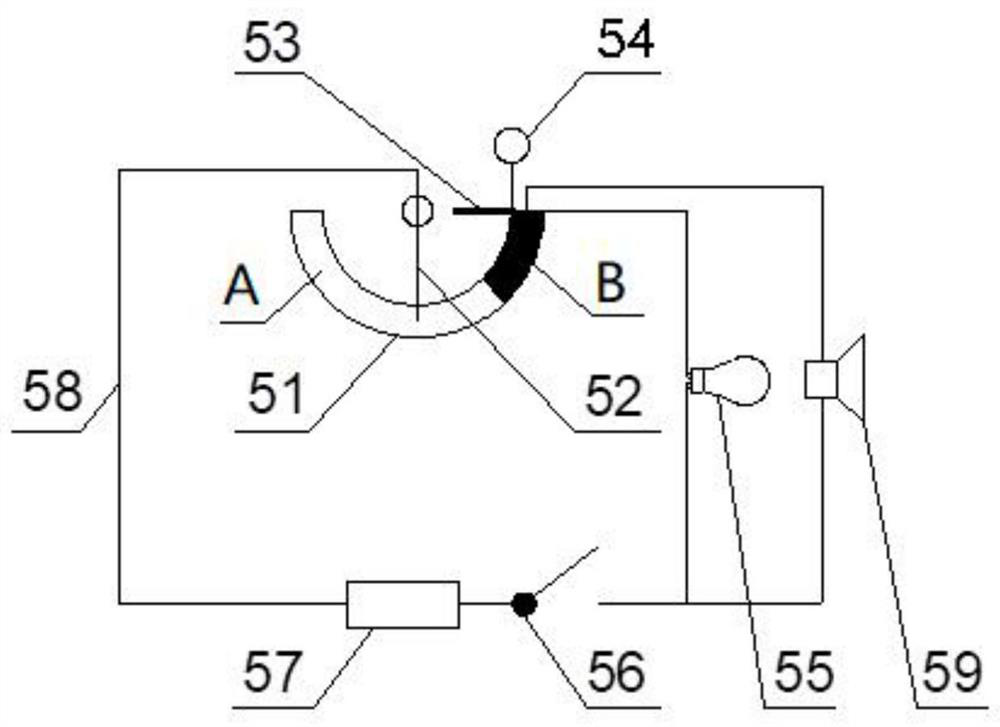

[0028] Such as figure 2 As shown, the superfill prompting instrument 5 includes a sliding rheostat 51, a slide bar 52, a one-way valve 53, a pulley 54, a reminder light 55, a closing switch 56, a storage battery 57, a closing circuit 58, and a warning bell 59.

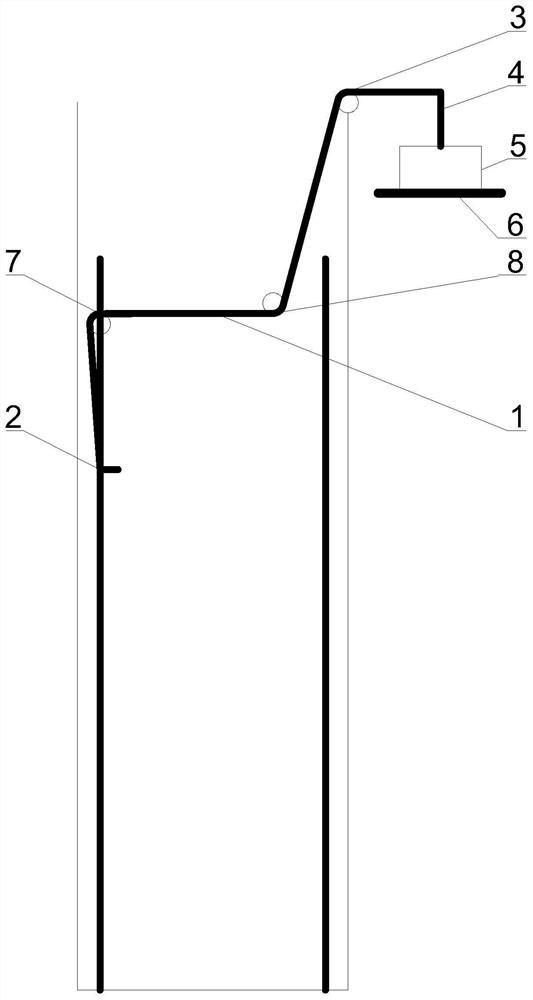

[0029] Such as image 3 As shown, a device for preventing overfilling of cast-in-situ piles includes a steel mesh 1, a triangular steel sheet 2, a pulley 3, a non-elastic stay rope 4, an overfilling prompter 5, a support 6, a pulley 7, and a pulley 8. The superfill prompting instrument 5 is placed on the support 6 and fixed with bolts. The super irrigation prompting instrument 5 is a portable super irrigation prompting instrument.

[0030] Determine the position of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com